NEMA 14 Hybrid Stepper Motor, 0.9°, 35*35mm, 2.7V/3.8V/5V/10V, 4 & 6 Wires

- Stock: In Stock

- Model: P-35BYGHM20-36

- SKU: P-35BYGHM20-36

$76.84

Ex Tax: $76.84

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Nema 14 stepper motor provides 0.9 deg step angle, 35*35mm frame size, 4 or 6 wires, 0.4A /0.5A / 0.8A 1.0A rated current and 2.7V / 3.8V / 5.0V or 10V rated voltage, with holding torque 7-15oz.in. 2 phase stepper motor with high quality, best price and wide applications. Cheap stepper motor price, high quality with CE, RoHS certified.

For more details, please visit here

Technical Parameter

- Step Angle Accuracy: ±5% (full step.no load)

- Resistance Accuracy: ±10%

- Inductance Accuracy: ±20%

- Temnerature Rise: 80℃ Max. (rated current, 2 phase on)

- Ambient Temperature: -10℃~+50℃

- Insulation Resistance: 100MΩ Min.500VDC

- Dielectric Strength: 500VAC·5mA for one Min.

- Shaft Radial Play: 0.06Max. (450 g-load)

- Shaft Axial Play: 0.08Max. (450 g-load)

- Insulation Class: Class B 130°

- Warranty: 12 months

- Certificate: CE, ROHs, ISO/SGS9001

Technical Specification

| Model | Rated Voltage | Rated Current | Phase Resistance | Inductance | Holding Torque | Motor Leads | Rotor Inertia | Weight | Length | ||

| Single Shaft | Double Shaft | ||||||||||

| P-35BYGHM20-1004A | P-35BYGHM20-1004B | 10V | 1A | 10Ω | 8mH | 7oz-in | 0.5kg-cm | 4 | 9g-cm2 | 0.1kg | 20mm |

| P-35BYGHM26-0804A | P-35BYGHM26-0804B | 3.8V | 0.8A | 4.8Ω | 10mH | 7oz-in | 0.5kg-cm | 4 | 9g-cm2 | 0.12kg | 26mm |

| P-35BYGHM28-0404A | P-35BYGHM28-0404B | 5V | 0.4A | 12.5Ω | 10mH | 13oz-in | 0.9kg-cm | 4 | 12g-cm2 | 0.14kg | 28mm |

| P-35BYGHM28-0504A | P-35BYGHM28-0504B | 10V | 0.5A | 20Ω | 10mH | 14oz-in | 1kg-cm | 4 | 12g-cm2 | 0.14kg | 28mm |

| P-35BYGHM34-0406A | P-35BYGHM34-0406B | 10V | 0.4A | 25Ω | 14mH | 15oz-in | 1.1kg-cm | 6 | 18g-cm2 | 0.17kg | 34mm |

| P-35BYGHM36-1004A | P-35BYGHM36-1004B | 2.7V | 1A | 2.7Ω | 14mH | 17oz-in | 1.2kg-cm | 4 | 18g-cm2 | 0.18kg | 36mm |

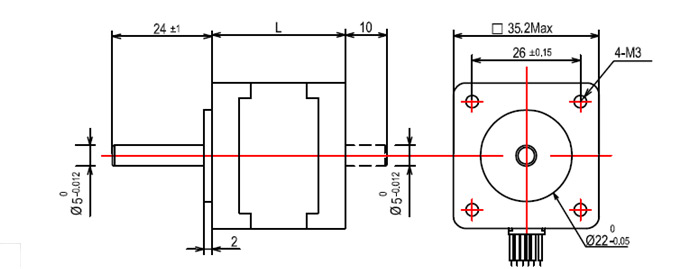

NEMA 14 Stepper Motor Dimension (Unit=mm)

NEMA 14 Stepper Motor Wiring Diagram

KNOWLEDGE BASE --- Heating principle of stepper motor driver

All types of motors that are usually used by users have iron cores and winding coils inside. Windings have resistance, energization will produce loss, the loss is proportional to the resistance and the square of the current, which is what we often call copper loss. If the current is not a standard DC or sine wave, it will also produce harmonic loss. What's more, iron core has hysteresis vortex effect and also produces loss in the alternating magnetic field and its magnitude is related to the material, current, frequency as well as voltage, which is called iron loss. Both copper loss and iron loss will show up in the form of heat, which affects the motor efficiency. Stepper motors generally are used for positioning accuracy and torque output, with relatively low efficiency, relatively large currents and high harmonic components. The frequency of current alternation also changes with the speed accordingly. Therefore, stepper motors generally have heat generation and the situation is more vortex than normal AC motors.