- Stock: In Stock

- Model: PEACO-D80M-04030

- SKU: PEACO-DCSERVO-1250

Available Options

Features

The DC servo motor control system, which is composed of a DC permanent magnet brushless synchronous servo motor and a corresponding servo drive, can be widely used in machine tools, textiles, plastics, printing and dyeing, printing, building materials, packaging, woodworking, chemical fields.

- The servo motor is composed of stator, rotor, feedback components, such as incremental photoelectric encoder, resolver, etc.

- The use of stator cores without shell allows large temperature gradients, high heat dissipation efficiency.

- DC servo motor has compact structure, high power density.

- Servo motor features small moment of inertia, fast response speed.

- Brushless DC servo motor comes with high-performance rare earth permanent magnetic materials, strong anti-demagnetization ability.

- DC servo motor with encoder has constant torque output in the entire speed range.

- 48 volt/ 72 volt servo motor provides high balance accuracy, stable high-speed operation, low noise, small vibration, fully sealed design.

- Servo motors are used in various industrial equipment, medical equipment, industrial tailoring machines, robotics, new energy, laser equipment, logistics automation, AGV vehicles, motion axes, and servo control systems. Such motors can convert voltage signals into torque and speed to control the mechanical components, so as to achieve the purpose of operation.

Specification

| Model | PEACO-D80M-04030-48V | PEACO-D80M-04030-72V |

| Rated Power | 1250W | 1250W |

| Rated Voltage | 48V DC | 72V DC |

| Rated Torque | 4.0N.M | 4.0N.M |

| Rated Speed | 3000 rpm | 3000 rpm |

| Rated Current | 32A ± 10% | 22A ± 10% |

| Moment Coefficient | 0.14A ± 10% N.m/A | 0.08A ± 10% N.m/A |

| Rotor Moment of Inertia | 2.8 ± 10% kg.m2x10-4 | 2.55 ± 10% kg.m2x10-4 |

| Line Back EMF | 7.15 ± 10% V/krpm | 10.5 ± 10% V/krpm |

| Line Inductance | 0.12± 10% mH | 0.12 ± 10% mH |

| Line Resistance | 0.033± 10% Ω | 0.033 ± 10% Ω |

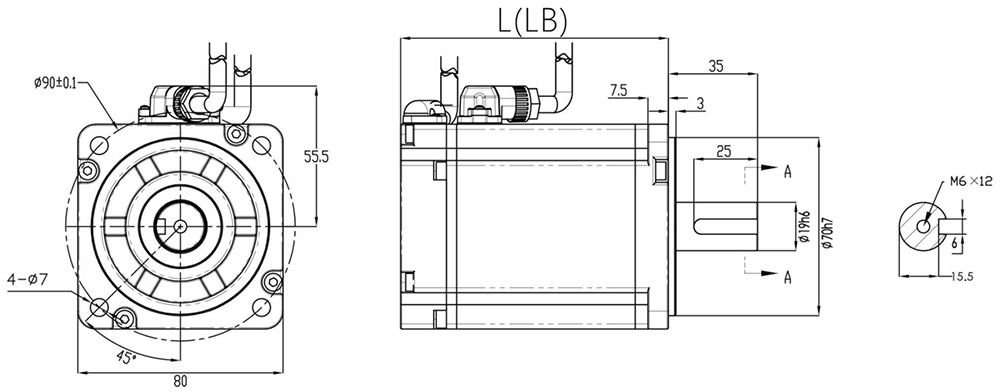

| Motor Length (L) | 174 (165) mm | 174 (165) mm |

| Motor Length with Brake (LB)* | 215 (205) mm | 215 (205) mm |

| Weight | 6.5kg/7.3kg | 6.5kg/7.3kg |

| Feedback Element X * (Optional) | Photoelectric incremental 2500 lines (E) / absolute value 17bit (A17) / rotary transformer (R) | |

| Insulation Resistance | DC 500V,>20MΩ (F) | |

| Operating Environment | -20℃~45℃, humidity -20℃~80℃ (No condensation) | |

| Rotation Direction | Counterlockwise (CCW) | |

| Protection Grade | IP65 (except for shaft opening), totally enclosed, self-cooled | |

| Certification | CE | |

| Warranty | 1 year | |

DC Servo Motor Dimension (Unit: mm)Note: * denotes optional or customized parameters and you can select every parameter in drop-down lists to complete your order.

KNOWLEDGE BASE --- DC Servo Motor Speed Control Method

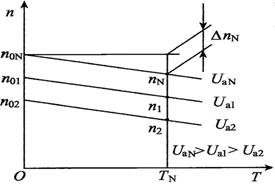

According to the speed formula of the DC servo motor, there are three basic speed adjustment methods of the DC motor, namely, adjusting the resistance R, adjusting the armature voltage U and adjusting the value of the magnetic flux Φ. But the speed regulation of armature resistance is not economical and the speed regulation range is limited. Therefore, it is rarely used.

1. When adjusting the armature voltage, if the armature current I is kept constant, the magnetic field flux Φ remains unchanged. It can be seen that the electromagnetic torque T of the motor remains unchanged and is a constant value. Therefore, the voltage regulation and speed regulation are also called speed regulation for constant torque.

2. When adjusting the magnetic and speed, the armature voltage U is usually kept at the rated voltage. Since the current in the excitation circuit can not exceed the rated value, the excitation current is always adjusted to a decreasing trend, which reduces the magnetic flux. It is called field weakening. At this time, the torque T also decreases, while the rotation speed increases. During the speed regulation process, the armature voltage U remains unchanged and if the armature current I remains unchanged, the output power remains the same. Therefore, the magnet and speed regulation are also called speed regulation with constant power.

The figure shows the mechanical characteristic curve of the DC motor in adjusting the armature voltage and adjusting the magnetic flux for speed regulation mode. In the figure, nN is the rated torque, TN is the rated speed, and △nN is the rated speed difference. It can be seen from the figure that when the armature voltage is adjusted, the mechanical characteristics of the DC motor are a set of parallel lines, that is, the slope of the mechanical characteristic curve remains unchanged, but only the ideal speed of the motor is changed, maintaining the original mechanical features. Therefore, the speed control of the servo feed system of the CNC machine tool adopts the speed control method of adjusting the armature voltage. The mechanical characteristics of permanent magnet DC servo motors just meet this speed regulation requirement. Therefore, the feed system of CNC machine tools often uses permanent magnet DC motors.

It can be seen from the figure that the magnetic and speed regulation not only changes the ideal speed of the motor, but also softens the mechanical characteristics of the DC motor. Therefore, the magnetic and speed regulation is mainly used for the speed regulation of the spindle motor of the machine tool.