- Stock: In Stock

- Model: PEACO-D60M-01930

- SKU: PEACO-DCSERVO-600

Available Options

Features

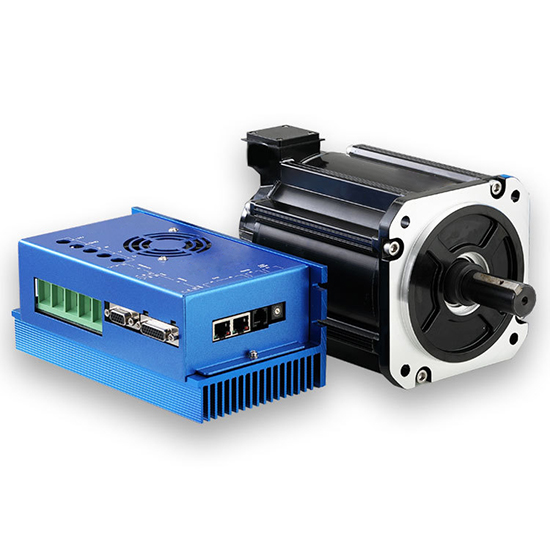

The DC servo motor control system, which is composed of a DC permanent magnet brushless synchronous servo motor and a corresponding servo drive, can be widely used in machine tools, textiles, plastics, printing and dyeing, printing, building materials, packaging, woodworking, chemical fields.

- The servo motor is composed of stator, rotor, feedback components, such as incremental photoelectric encoder, resolver, etc.

- The use of stator cores without shell allows large temperature gradients, high heat dissipation efficiency.

- DC servo motor has compact structure, high power density.

- Servo motor features small moment of inertia, fast response speed.

- Brushless DC servo motor comes with high-performance rare earth permanent magnetic materials, strong anti-demagnetization ability.

- DC servo motor with encoder has constant torque output in the entire speed range.

- 12 volt/ 24 volt servo motor provides high balance accuracy, stable high-speed operation, low noise, small vibration, fully sealed design.

- Servo motors are used in various industrial equipment, medical equipment, industrial tailoring machines, robotics, new energy, laser equipment, logistics automation, AGV vehicles, motion axes, and servo control systems. Such motors can convert voltage signals into torque and speed to control the mechanical components, so as to achieve the purpose of operation.

Specification

| Model | PEACO-D60M-01930-24V | PEACO-D60M-01930-48V | PEACO-D60M-01930-72V |

| Rated Power | 600W | 600W | 600W |

| Rated Voltage | 24V DC | 48V DC | 72V DC |

| Rated Torque | 1.91N.M | 1.91N.M | 1.91N.M |

| Rated Speed | 3000 rpm | 3000 rpm | 3000 rpm |

| Rated Current | 35A ± 10% | 16A ± 10% | 11A ± 10% |

| Moment Coefficient | 0.058A ± 10% N.m/A | 0.13A ± 10% N.m/A | 0.18A ± 10% N.m/A |

| Rotor Moment of Inertia | 0.82 ± 10% kg.m2x10-4 | 0.85 ± 10% kg.m2x10-4 | 0.85 ± 10% kg.m2x10-4 |

| Line Back EMF | 3.5 ± 10% V/krpm | 7.9 ± 10% V/krpm | 11.0 ± 10% V/krpm |

| Line Inductance | ± 10% mH | 0.4 ± 10% mH | ± 10% mH |

| Line Resistance | ± 10% Ω | 0.17 ± 10% Ω | ± 10% Ω |

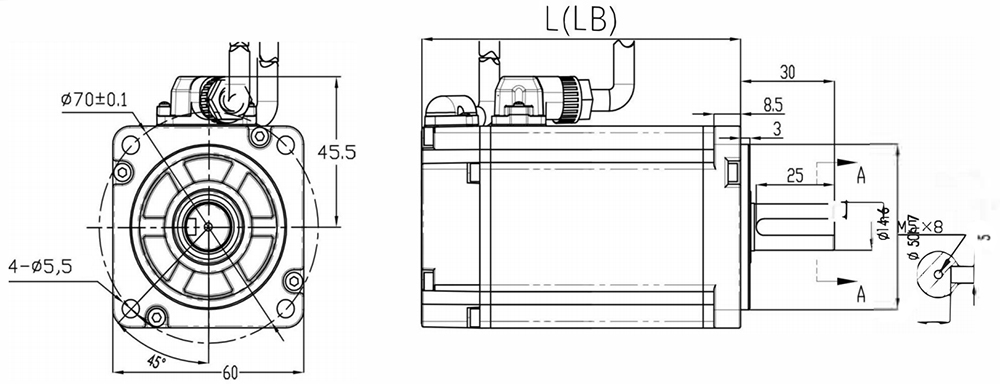

| Motor Length (L) | 137 (128) mm | 125 (116) mm | 125 (116) mm |

| Motor Length with Brake (LB)* | 127 (118) mm | 163 (153) mm | 163 (153) mm |

| Weight | 1.75kg/2.15kg | 1.75kg/2.15kg | 1.75kg/2.15kg |

| Feedback Element X * (Optional) | Photoelectric incremental 2500 lines (E) / absolute value 17bit (A17) / rotary transformer (R) | ||

| Insulation Resistance | DC 500V,>20MΩ (F) | ||

| Operating Environment | -20℃~45℃, humidity -20℃~80℃ (No condensation) | ||

| Rotation Direction | Counterlockwise (CCW) | ||

| Protection Grade | IP65 (except for shaft opening), totally enclosed, self-cooled | ||

| Certification | CE | ||

| Warranty | 1 year | ||

DC Servo Motor Dimension (Unit: mm)Note: * denotes optional or customized parameters and you can select every parameter in drop-down lists to complete your order.

KNOWLEDGE BASE --- DC Servo Motor TypesIn the CNC machine tools, some types of DC servo motors are used in the feed system commonly.

1. Small Inertia DC Servo Motor

Small inertia DC servo motor is generally the hydromagnetic type and the armature windings are available in phase-free armature type, printed armature type and hollow cup armature type. Because the small inertia DC motor minimizes the rotational inertia of the armature. Therefore, the fastest response speed can be obtained. In the early CNC machine tools, this type of servo motor is more widely used.

2. DC Torque Motor

DC torque motor is also known as large inertia and wide speed regulation DC servo motor. On the one hand, because of its larger rotor diameter, the number of turns of the coil winding is increased, the torque is larger and it can work for a long time at a large overload torque. Therefore, it can be directly connected with the screw and no intermediate gearing is required. On the other hand, because it has no loss of excitation circuit, its size is smaller than other similar DC servo motors. It also has an outstanding feature, which is able to achieve smooth operation at a lower speed, and the minimum speed can reach 1r/min, or even 0.1r/min. Therefore, this kind of servo motor has been widely used in CNC machine tools.

3. Brushless DC Servo Motor

The brushless DC servo motor is also called no rectifier motor, which does not have commutator, is composed of synchronous motor and inverter and the inverter is controlled by the rotor position sensor mounted on the rotor. This kind of DC servo motor is essentially a kind of AC speed control motor, because its speed control performance can reach the level of DC servo generator. There are no commutation device and brush parts, which greatly improves the service life of the motor.