The reversing contactor is a very common electrical control component used to control the direction of motor operation, which plays an important role in various mechanical equipment and automation systems. Its main function is to control the opening and closing of the circuit and realize the functions of forward reverse, and start-stop control of electrical equipment.

Reversing Contactor Structure

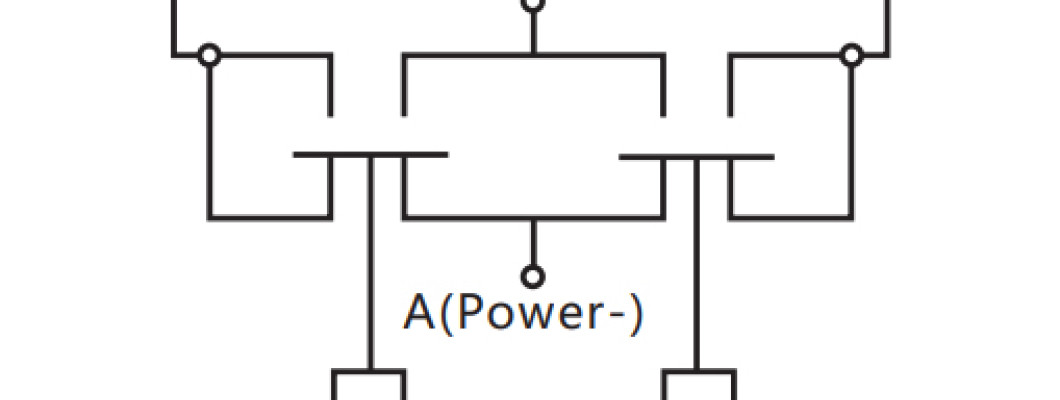

The structure of the reversing contactor mainly includes electromagnets, contacts, electromagnetic coils, and shells. The electromagnet is the critical component of the reversing contactor, which is composed of an iron core, coil, and terminal. The contact is a key part of the reversing contactor, which is usually made of silver alloy material with good electrical conductivity and wear resistance. The electromagnetic coil is the control part of the reversing contactor. When the electromagnetic coil is energized, it will generate a magnetic field to attract the iron core, causing the contact between the stator and the rotor to move, thereby realizing the switching of the circuit. The shell is usually made of plastic or metal materials and it is the internal parts to protect the contactor.

Reversing Contactor Working Principle

The principle of the reversing contactor is based on the characteristics of the current flow direction. By alternately switching the power line, it can be used for the forward and reverse control of the DC motor.

Under normal circumstances, when the electromagnet is not energized, the reversing contactor is in the disconnected state. However, when the electromagnet is energized, the magnetic field generated by the electromagnet will attract the transmission mechanism, so that the contacts are closed, the circuit is energized, and the equipment starts to work. When the electromagnet is powered off, the transmission mechanism rebounds, the contacts are disconnected, the circuit is powered off, and the equipment stops working.

Applications of DC Reversing Contactor

The reversing contactor is one of the contractors and has the advantages of simple structure, convenient use, maintenance-free, and high reliability. As an important component to control the running direction of the motor, the forward reverse contactor has important application value in industrial production and is widely used in stacker trucks, bridge boarding trucks, car tailgates, car lifts, tire stripping machines, lifting platforms, dump trucks, cranes, aerial work platforms, presses, home elevators, truck-mounted cranes, etc., etc. Among these devices, the reversing contactor is mainly used for forward and reverse rotation and start-stop control. For example, a reversing contactor is used to control the forward and reverse of the motor in a crane. In the machine tool, the reversing contactor is used to control the start and stop and forward and reverse of the motor. In the elevator, the reversing contactor is used to control the start and stop of the motor, etc.

Related Posts:

- Difference between Auxiliary and Main Contacts

- What is DC Reversing Contactor?

- High Voltage DC Contactor Price

- What is Contactor?

- DC Contactor for Electric Vehicles

- DC Contactor Working Principle

- How to Check AC Contactor?

- What is high voltage dc contactor ?