With the rapid development of new energy vehicles and charging facilities nowadays, the market capacity of electric vehicle DC contactors, one of their key electrical components, has also expanded continually. DC contactors for electric vehicles are widely used in power grids and new energy equipment. Given the special needs in this emerging industry, how will design engineers of DC electrical appliances choose suitable DC contactor relays for electric vehicles for their design ideals? The following are the principles, application, and adaptability of DC contactors for electric vehicles.

DC Contactor Working Principle

When the contactor coil is energized, the coil current generates a magnetic field, which makes the static iron core generate electromagnetic attraction to attract the moving iron core and then drives the contact action - the normally closed contact is disconnected, the normally open contact is closed and both are linked. When the coil is powered off, the electromagnetic suction force disappears and the armature is released under the action of the release spring to restore the contacts - the normally open contacts are disconnected and the normally closed contacts are closed.

DC contactor relay has a wide selection of contactor coil voltages, including 12V DC contactor / 24V DC contactor/ 48V DC contactor. The control coil of the DC contactor relay is classified into double coil and single coil. The starting power of the dual coil is large, but the holding power is small. On the contrary, the starting power of a single coil is very small and the holding power is the same as the starting power.

Application of Electric Vehicle DC Contactor

The electric vehicle DC contactor adopts a modular design and design engineers can assemble the contact number and the contact form (normally open, closed, and reversing) according to customer requirements with as few parts as possible. this series of DC contactor replays have high breaking voltage and the arc is extinguished through a transverse blowing magnetic field. The breaking voltage can reach 220VDC. Such DC contactors for electric vehicles are suitable for frequency converters, communication power supplies, battery cars, traction locomotives, and uninterruptible power supply systems.

DC Contactor Application in Electric Vehicles

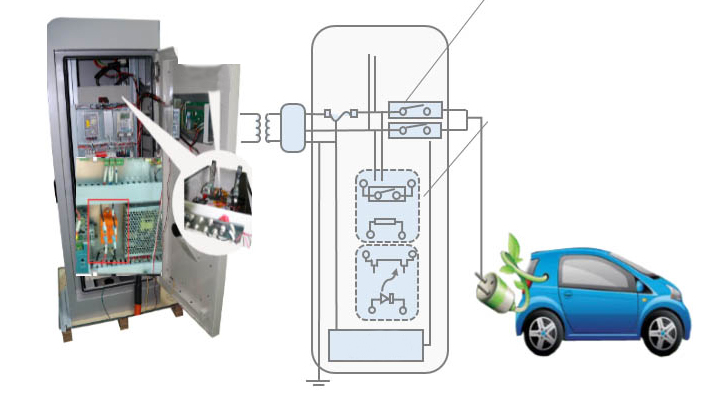

DC contactors for electric vehicles can be configured in the battery system and the inverter of an electric vehicle. On the one hand, when the system stops running, it plays the role of isolation. On the other hand, when the system is running, it plays the role of connection. Therefore, when electric vehicles fail, the energy storage system can be safely separated from the vehicle's electrical system, playing the role of breaking the circuit. Additionally, DC contact can work as a power control device in other auxiliary circuits.

DC Contactor Application in Charging Piles

High-voltage DC contactors are also used for the DC output side of the DC charging pile, charging station, and car charger. When the contactor is closed, it connects the charging pile with the car. On the contrary, when disconnected, it isolates the connection between the charging pile and the outside for safety protection.

Important Technical Indicators

a) High voltage DC contactor plays the role of isolating the power supply terminal and the load terminal after the system stops running (rated insulation voltage Ui).

b) The DC contactor plays the role of connecting the power supply terminal and the load terminal when the system is running (resistive current Ith).

c) It also has the function of breaking the circuit in case of failure (the highest operating voltage U).

Adaptive Design of High Voltage DC Contactor

1. Environmental Adaptability Design

Compared with general industrial contactors, the DC contactor for electric vehicles has higher requirements on the environmental conditions and must meet basic conditions, such as a wide temperature range, high protection level, and high vibration resistance.

1) High and low-temperature design: It is necessary to meet the temperature requirements for the normal use of electric vehicles and charging piles in harsh environments. As for the DC contactor, its storage environment temperature is up to -55℃~+125℃, the normal working environment temperature is -25~+40℃ and the ambient temperature is -40~+85℃ under extreme conditions.

2) Protection grade design: The high voltage DC contactor can be used normally in harsh environments, including rain and dust environments. Additionally, the DC contactor should completely prevent dust from entering and meet the requirements of short-term water immersion. Besides, the protection grade reaches IP67.

3) Anti-vibration performance design: The high voltage DC contactor needs to have strong anti-vibration and shock resistance, satisfying the special needs of the car for bumpy vibration in various road conditions.

2. Safety and Reliability Design

Safety and reliability are the first and most critical factors to measure the DC contactor of electric vehicles, which mainly reflects the arc extinguishing ability and insulation voltage.

The DC arc has some features, for example, there is no zero-crossing point and the arc is difficult to extinguish after arcing. The DC contactor structure is designed as a double-breakpoint direct-acting motion form. The arc-extinguishing technology of filling the compressed gas in the sealed arc-extinguishing cavity can achieve good arc-extinguishing ability.

The main principle is: that the arc and the filled gas generate high-pressure gas after the arc is heated, the increase of the gas pressure makes the thermal dissociation greatly decrease, and the pressure difference between the arc gap and the arc extinguishing chamber accelerates the gas movement, then the cooling effect is intensified and the arc is quickly extinguished.