- Stock: In Stock

- Model: PEACO-130TM-15020C5

- SKU: PEACO-DCSERVO-315

Available Options

Features

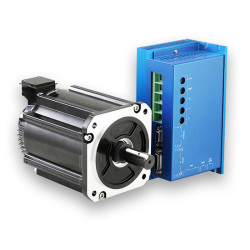

The DC servo motor control system, which is composed of a DC permanent magnet brushless synchronous servo motor and a corresponding servo drive, can be widely used in machine tools, textiles, plastics, printing and dyeing, printing, building materials, packaging, woodworking, chemical fields.

- The brushless DC servomotor is composed of stator, rotor, feedback components, such as incremental photoelectric encoder, resolver, etc.

- The use of stator cores without shell allows large temperature gradients, high heat dissipation efficiency.

- DC servo motor has compact structure, high power density.

- Servo motor features small moment of inertia, fast response speed.

- Brushless DC servo motor comes with high-performance rare earth permanent magnetic materials, strong anti-demagnetization ability.

- DC servo motor with encoder has constant torque output in the entire speed range.

- Reliable DC servo motor provides high balance accuracy, stable high-speed operation, low noise, small vibration, fully sealed design, can provide high performance with BLDC servo drive.

- Servo motors are used in various industrial equipment, medical equipment, industrial tailoring machines, robotics, new energy, laser equipment, logistics automation, AGV vehicles, motion axes, and servo control systems. Such motors can convert voltage signals into torque and speed to control the mechanical components, so as to achieve the purpose of operation.

Specification

Model: PEACO-130TM-15020C5

| Rated Output (kW) | 3.15 | Number of Poles | 10 |

| Rated Voltage (V) | DC 48/72 | Insulation Class | F |

| Rated Speed (rpm) | 2000 | Max. Speed (rpm) | 2200 |

| Rated Current (A) | 75.5 ± 10% | Instantaneous Max. Current (A) | 151 ± 10% |

| Rated Torque (N.m)* | 15 | Instantaneous Peak Torque (N.m) | 30 |

| Line Resistance (Ω) | 0.018 ± 10% (25℃) | Line Inductance (mH) | 0.079 ± 10% |

| Line Back EMF (V/krpm) | 12±10% | Torque Coefficient (Nm/A) | 0.2 ± 10% |

| Rotor Moment of Inertia (kg.m2x10-4) | 18.2 ± 10% | Feedback Component | Incremental encoder, 2500 PPR / absolute encoder |

| Static Torque (N.m) | >19 | Brake Working Voltage | DC24V 2A |

| Insulation Resistance (MΩ) | DC 500V, > 20MΩ | Noise (dB) | ≤ 60dB, none special noise |

| Working Time | Continuous | Vibration Class | V15 |

| Environment Temperature | -20℃~40℃ | Environment Humidity | -20℃~80℃ (No condensation) |

| Excitation | Permanent Magnet | Mouting | Flange method |

| Drive Method | Direct Drive | Motor Weight (kg) | 12.8 |

| Certification | CE | Warranty | 1 year |

| Enclosure | Tolly Enclosed, Self-cooled, IP 65 (except for shaft opening) | ||

| Rotation Direction | Counterlockwise (CCW) | ||

Note: * Rated torque is the continuous allowable torque at 40℃ with a Fe heatsink of 400*400*20.

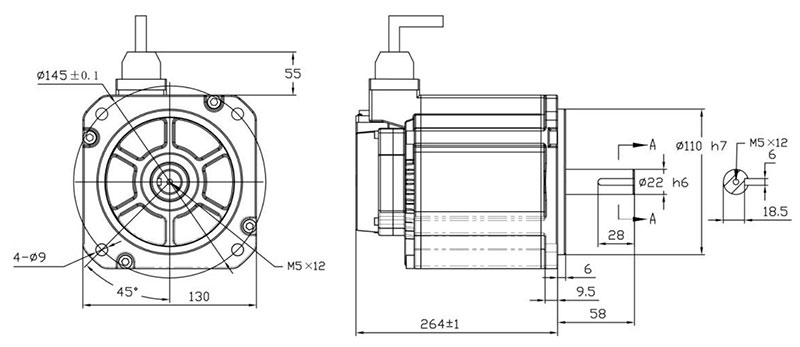

BLDC Servomotor Dimension (Unit: mm)

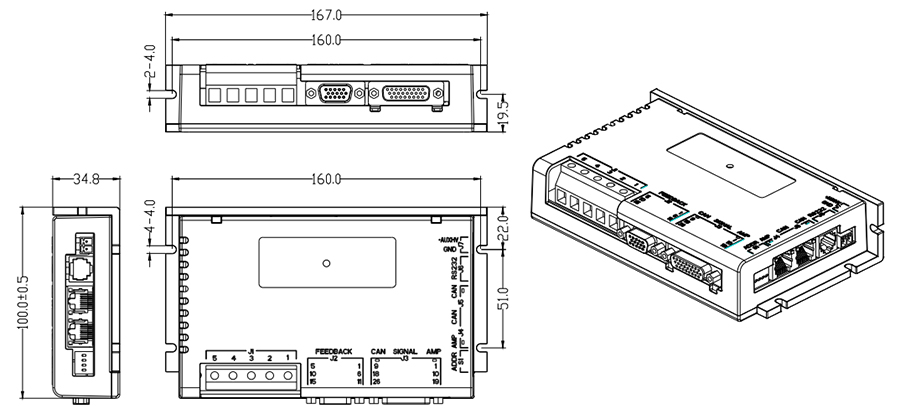

BLDC Servomotor Driver Dimension (Unit: mm)

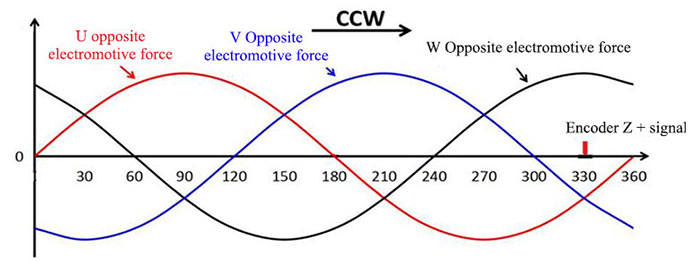

Relationship between Encoder Zero Point and Motor Phase

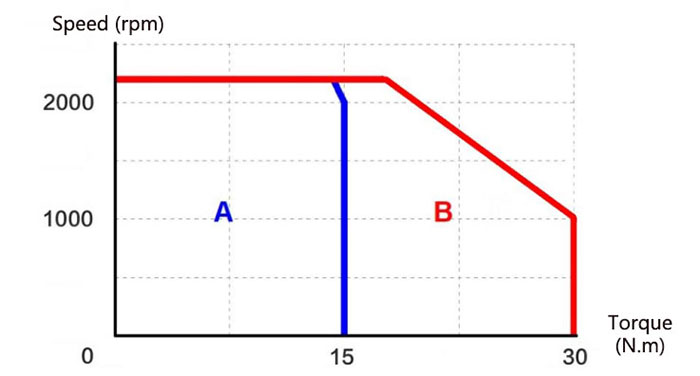

BLDC Servomotor Torque - Speed Graph

A: Continuous Duty Zone, B: Intermittent Duty Zone

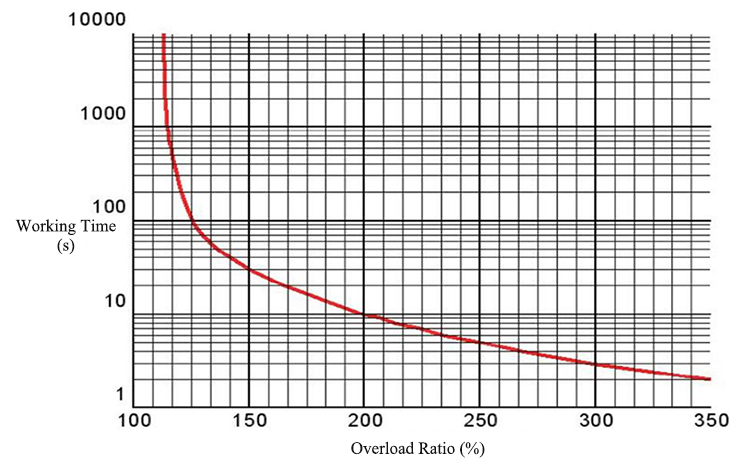

BLDC Servomotor Overload Characteristics

Note:

1. The characteristics are measured in the warm-boot conditions at 40℃.

2. The above characteristics do not supply 100% output for continuous running.

3. Please make sure that the effective torque is in the range of T-N characteristics' continuous duty zone.

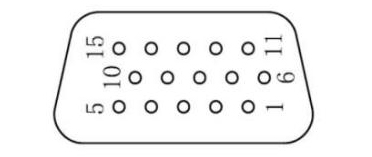

Connectors

| Power Line Socket | Socket Numbers | Yellow Green | Red | Blue | Black |

| Signal Leads | PE | U | V | W |

| Socket Numbers | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| Signal Leads | U+ | 5V | 0V | V+ | Z- | Z+ | W+ | B- | B+ | A- | A+ |