- Stock: In Stock

- Model: PEACO-1-FC280-2S/4T-11G/15P

- SKU: PEACO-VFD-1511

Available Options

1-Phase 220V to 3-Phase 380V VFD is a customizable VFD for 3 phase motor speed control with optional input and output voltages, featuring 15 hp (11.2kW) rated power. Cost-effective VFD adopts unique control method to realize high moment of force, high precision and wide speed regulating range driving, especially used for elevator.

Our VFD are suitable for single phase and split phase input power supply.

Navigation: Motor Controls > Variable Frequency Drives > 1-Phase 220V to 3-Phase 380V VFD > 15 hp (11 kW) VFD, 1-Phase 220V to 3-Phase 380V/440V VFD

Specifications

| Basics | Model | PEACO-1-FC280-2S/4T-11G/15P | |

| Rated Capacity | 15 hp (11 kW) | ||

| Rated Input Current | 77.0A | ||

| Rated Output Current | 25.0A | ||

| Certification | CE | ||

| Warranty | 24 months | ||

| Applicable Motor Output | 11kW | ||

| Power | Input Rated Voltage* | Single phase AC 220 V (-15%~+20%) and Split voltage | |

| Output Rated Voltage* | Three phase AC 380V (-15%~+15%) | ||

| Rated Frequency | 1.0~3200Hz | ||

| Robust Design | IGBT current > 2 times of inverter output current, Capacitor > 50uF/A | ||

| PCB aging test | 100% test, 50°C, 12 hours. | ||

| Finished products aging test | 100% test, 50°C, 24 hours. | ||

| Control Feature | Control System | VF Control / Open Sensor Vector Control / Closed loop Vector (PG card - for lift/elevator) | |

| Output Frequency Resolution | 0.1Hz | ||

| Torque Characteristics | Including the auto-torque, auto-slip compensation, starting torque can be 0.5 Hz/150% (V/f), 1 Hz/150% (SVC),0 Hz/180% (FVC) | ||

| Overload Endurance | 150% / 120s, 160% / 60s, 180% / 10s, 200% / 1s | ||

| Accel / Decel Time | 0.1~65000s. (can be set individually) | ||

| Torque Boost | Automatically torque boost, manually torque boost: 0.1%~30.0% | ||

| Stall Prevention Level | 20~200%, setting of Rated Current | ||

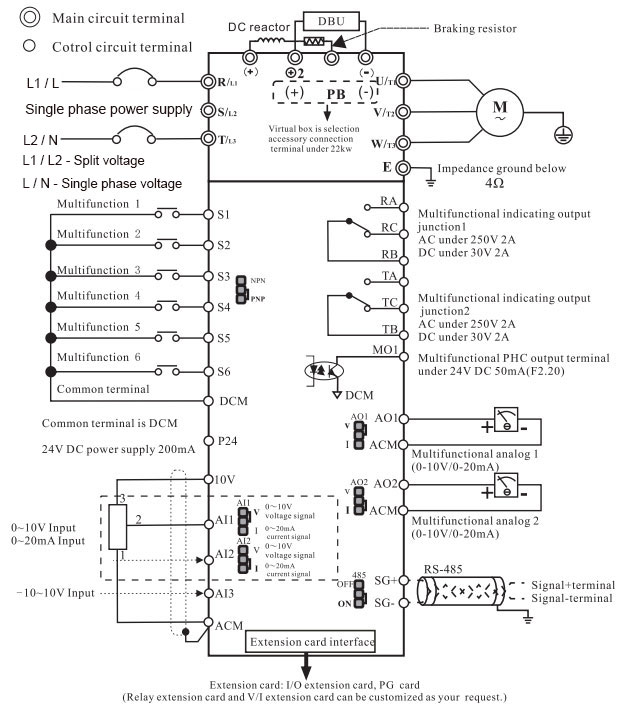

| Operating Feature | Input / Output Terminals | Keypad | Removable |

| Input terminals | 6 multifunctional inputs, one can be work as high speed pulse Input. 3 programmable analog input: AI1, AI2, AI3: 0~10V / 4~20mA. |

||

| Output terminals | 2 Groups relay outputs, 1 open collector outputs. 2 Analog outputs, 0~10V / 4~20mA. |

||

| Communication Terminals | Build-in standard RS485 communication interface. MODBUS-RTU communication protocol. | ||

| Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | ||

| Jog Operation | Jog operation frequency: 0.0Hz~maximum frequency. Jog acceleration/deceleration time: 0.1s~3600.0s. | ||

| Other Function | AVR, S-curve, Over-Voltage Stall Prevention, DC Braking, Fault Records, Adjustable Carried Frequency, Starting Frequency Setting of DC Braking, Over-Current Stall Prevention, Momentary Power Loss Restart, Reverse Inhibition, Frequency Limits, Parameter Lock/Reset. | ||

| Protection | Over Voltage, Over Current, Under Voltage, Overload, Electronic thermal, Overheating, Self-testing. | ||

| Others | Including EMC Filter (C2/C3 Standard) | ||

| Cooling | Forced air-cooling | ||

| Installation Location | Altitude 1,000 m or below, keep from corrosive gasses, liquid and dust. | ||

| Ambient Temperature | -10°C~+40°C (Non-Condensing and not frozen) | ||

| Storage Temperature | -20°C~+60°C | ||

| Ambient Humidity | Below 90% RH (non-condensing) | ||

| Vibration | 9.80665m/s2 (1G) less than 20Hz, 5.88m/s2 (0.6Gat) 20 to 50Hz | ||

| External Accessories* |

Matched optional input EMC filter, output EMC filter, input AC reactor, output AC reactor, energy regenerated reactor, harmonic filter, sine wave filter (excluding VFD price). |

||

1. * denotes the parameters are optional or customized and please select every parameter in drop-down lists to complete your order.

2. Please contact us for external accessories catalogue and price.

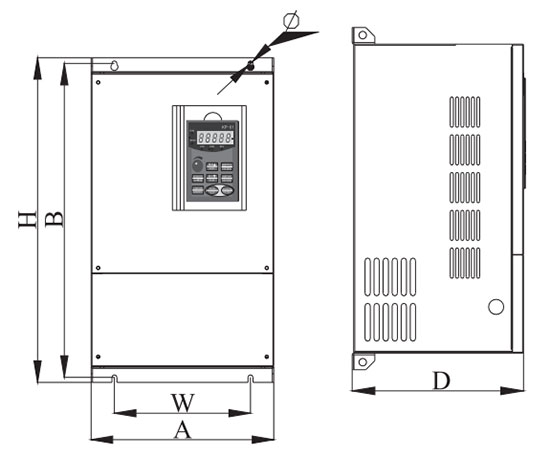

AC Drive Dimension (Unit: mm)

| A | H | D | W | B | Φ | Weight |

| 160 | 247 | 177 | 148 | 235 | Φ5.5 | 3.5kg |

Control Circuit Diagram for Industrial Motor

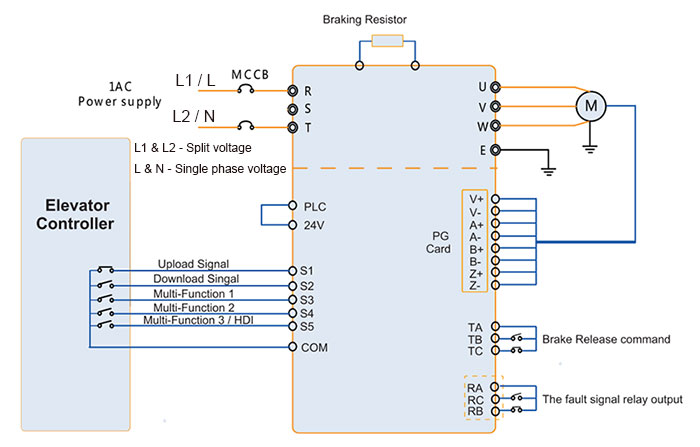

Control Circuit Diagram for Lift or Elevator Motor

KNOWLEDGE BASE

Single Phase 220V to Three Phase 380V Converter

The principle of frequency converter is to adopts the principle of frequency conversion technology and microelectronics technology to control the power control equipment of AC motors by changing the working power frequency of the motor and converts the industrial frequency AC power with fixed voltage and frequency into Alternating Current with variable frequency and voltage.

The output waveform of variable frequency drive (VFD) is an analog sine wave, which is mainly used for 3 phase motor speed control, also called variable speed drive (VSD), AC drive, micro drive or inverter drive. The frequency converter is mainly composed of rectifier (AC to DC), filtering, inverter (DC to AC), braking unit, drive unit, detection unit and micro processing unit, etc. The phase converter mainly adopts the AC-DC-AC method (VVVF frequency conversion or vector control frequency conversion). First of all, the industrial frequency AC power supply is converted into a DC power supply through a rectifier and then the DC power supply is converted into an AC power supply with controllable frequency and voltage to supply electric motor.

The single phase 220V to three phase 380V converter converts the power frequency AC 220V power supply into a DC power supply through a rectifier (voltage doubler rectification) and then converts the DC power supply into a three-phase 380V AC power supply with controllable frequency and voltage to supply the motor.