- Stock: In Stock

- Model: PEACO-1-FC280-2S/4T-7.5G/11P

- SKU: PEACO-VFD-1075

Available Options

Specifications

| Basics | Model | PEACO-1-FC280-2S/4T-7.5G/11P | |

| Rated Capacity | 10 hp (7.5 kW) | ||

| Rated Input Current | 53.0A | ||

| Rated Output Current | 17.0A | ||

| Certification | CE | ||

| Warranty | 24 months | ||

| Applicable Motor Output | 7.5kW | ||

| Power | Input Rated Voltage* | Single phase AC 220 V (-15%~+20%) and Split voltage |

|

| Output Rated Voltage* | Three phase AC 380V (-15%~+15%) |

||

| Rated Frequency | 1.0~3200Hz | ||

| Robust Design | IGBT current > 2 times of inverter output current, Capacitor > 50uF/A | ||

| PCB aging test | 100% test, 50°C, 12 hours. | ||

| Finished products aging test | 100% test, 50°C, 24 hours. | ||

| Control Feature | Control System | VF Control / Open Sensor Vector Control / Closed loop Vector (PG card) | |

| Output Frequency Resolution | 0.1Hz | ||

| Torque Characteristics | Including the auto-torque, auto-slip compensation, starting torque can be 0.5 Hz/150% (V/f), 1 Hz/150% (SVC),0 Hz/180% (FVC) | ||

| Overload Endurance | 150% / 120s, 160% / 60s, 180% / 10s, 200% / 1s | ||

| Acc/ Dec Time | 0.1~65000s. (can be set individually) | ||

| Torque Boost | Automatically torque boost, manually torque boost: 0.1%~30.0% | ||

| Stall Prevention Level | 20~200%, setting of Rated Current | ||

| Operating Feature | Input / Output Terminals | Keypad | Removable |

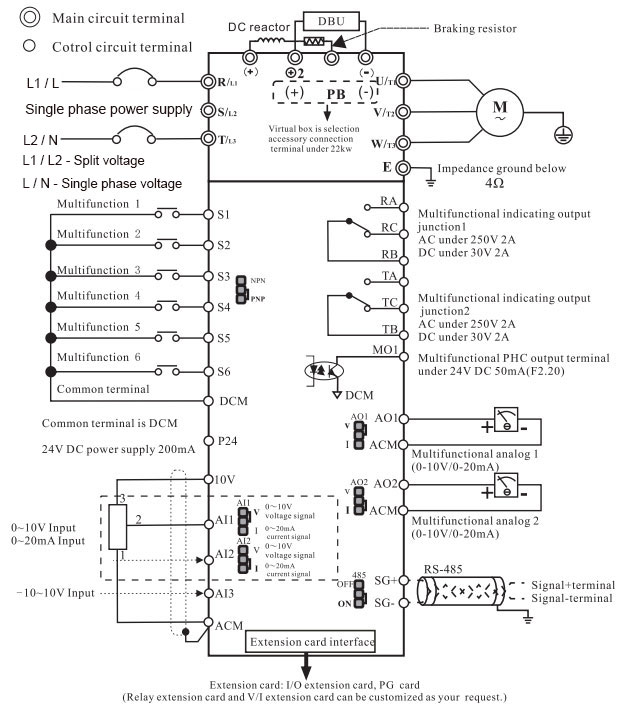

| Input terminals | 6 multifunctional inputs, one can be work as high speed pulse Input. 3 programmable analog input: AI1, AI2, AI3: 0~10V / 4~20mA. |

||

| Output terminals | 2 Groups relay outputs, 1 open collector outputs. 2 Analog outputs, 0~10V / 4~20mA. |

||

| Communication Terminals | Build-in standard RS485 communication interface. MODBUS-RTU communication protocol. | ||

| Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | ||

| Jog Operation | Jog operation frequency: 0.0Hz~maximum frequency. Jog acceleration/deceleration time: 0.1s~3600.0s. | ||

| Other Function | AVR, S-curve, Over-Voltage Stall Prevention, DC Braking, Fault Records, Adjustable Carried Frequency, Starting Frequency Setting of DC Braking, Over-Current Stall Prevention, Momentary Power Loss Restart, Reverse Inhibition, Frequency Limits, Parameter Lock/Reset. | ||

| Protection | Over Voltage, Over Current, Under Voltage, Overload, Electronic thermal, Overheating, Self-testing. | ||

| Others | Including EMC Filter (C2/C3 Standard) | ||

| Cooling | Forced air-cooling | ||

| Installation Location | Altitude 1,000 m or below, keep from corrosive gasses, liquid and dust. | ||

| Ambient Temperature | -10°C~+40°C (Non-Condensing and not frozen) | ||

| Storage Temperature | -20°C~+60°C | ||

| Ambient Humidity | Below 90% RH (non-condensing) | ||

| Vibration | 9.80665m/s2 (1G) less than 20Hz, 5.88m/s2 (0.6Gat) 20 to 50Hz | ||

| External Accessories* |

Matched optional input EMC filter, output EMC filter, input AC reactor, output AC reactor, energy regenerated reactor, harmonic filter, sine wave filter (excluding VFD price). |

||

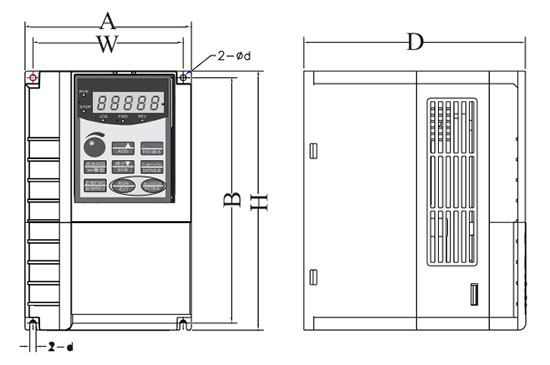

AC Drive Dimension (Unit: mm)

| A | H | D | W | B | Φ | Weight |

| 160 | 247 | 177 | 148 | 235 | Φ5.5 | 3.5kg |

Control Circuit Diagram for Industrial Motor

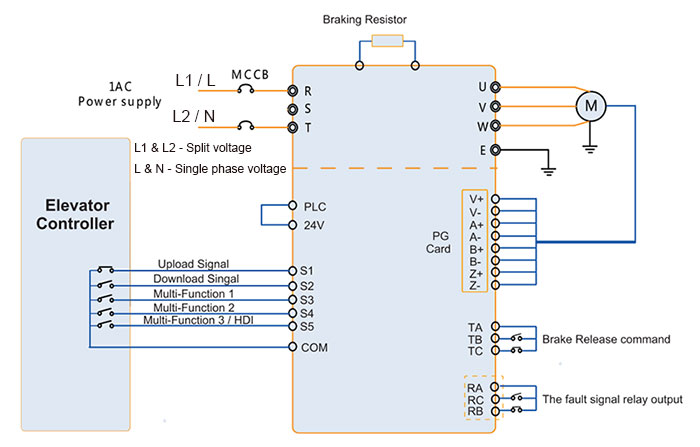

Control Circuit Diagram for Lift or Elevator Motor

KNOWLEDGE BASE --- Can a 380v motor run on 220v?

Many people ask this question---Can 220v be converted to 380v with a frequency converter to drive a three-phase motor? The answer is YES.

A variable frequency drive (VFD) can completely convert 220V household electricity into 380V industrial electricity, which is used to drive three-phase asynchronous motors. The output is an analog sine wave three-phase alternating current (AC) with adjustable frequency and voltage. It is not a standard sine wave. Usually it can only be used to control a three-phase asynchronous motor and the motor speed can be adjusted by changing the output frequency of the inverter. It cannot be connected to use on single-phase loads.

The main circuit of the AC drive generally adopts the AC-DC-AC working mode, namely, the alternating current (AC) is converted into direct current (DC) and then the high-power switch tube inside the inverter is turned on or off according to a certain procedure and the inverter is turned into a simulated 3-phase sine wave AC output.

There are many kinds of VFDs on peacosupport.com, single phase VFD, 1 phase to 3 phase VFD, three phase VFD, 1-phase 220V to 3-phase 380V VFD, 1-phase 220V to 3-phase 400V VFD, 1-phase 220V to 3-phase 440V VFD, etc., which are usually designed for AC motor speed control in the industry. Most of them use industrial three-phase AC as the input power source, thus the design capacity of inverter drive needs to be increased.