- Stock: In Stock

- Model: Peaco-TS-N502

- SKU: PEACO-DYN-502

Available Options

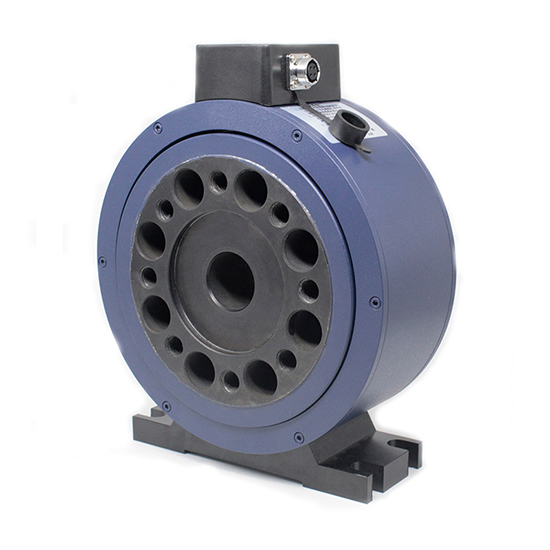

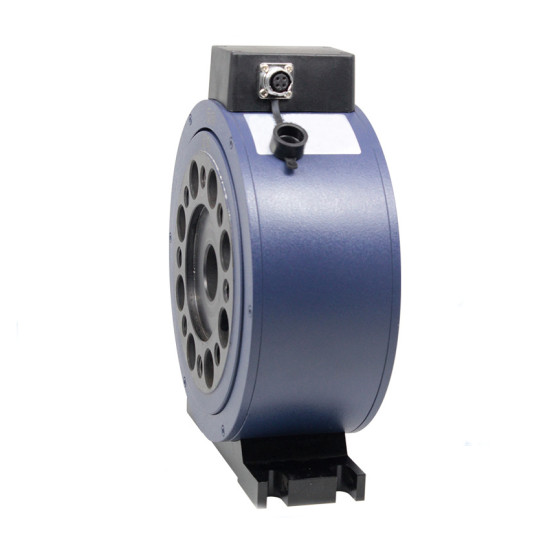

Rotary torque sensor is a non-contact torque sensor, installed between a power source and a load to accurately measure torque. 5 Nm-50000 Nm capacity, easy to get forward and reverse torque signal without repeated zero adjustment, no bearings between stationary housing and rotating disc, suitable for high-speed rotating and for static measurement and dynamic measurement.

Rotary Torque Sensor Features- Wide range of torque sensor capacity. 5 Nm-50000 Nm. 5 Nm, 100 Nm, 200 Nm, 500 Nm, 1000 Nm, 2000 Nm, 3000 Nm, 5000 Nm, 10000 Nm, 20000 Nm, 30000 Nm, 50000 Nm available for your choice.

- A transmitter to output standard signals to PLC, DCS, and other systems will be provided for you to obtain direct readings. The output signal can be 0~5V, 0~10V, 4-20mA, and 5~15kHz.

- Strong anti-interference (power and signal isolation greatly reduce interference), high precision (overall accuracy 0.2%F.S.), wireless transmission without slip ring and high-speed response, good stability, digital output signal function, small size, lightweight, easy to install.

- Non-contact energy and signal transmission.

- The forward and reverse torque signals can be continuously transmitted without repeated zero adjustment.

- There are no bearings between the shell and the rotating disk, which can be suitable for long-term high-speed operation.

- The rotary torque sensor can transmit a non-rotating torque signal and a rotating torque signal with a transmitter/amplifier.

- Model: Peaco-TS-N502

- Capacity: 5 Nm-50000 Nm. 5 Nm, 100 Nm, 200 Nm, 500 Nm, 1000 Nm, 2000 Nm, 3000 Nm, 5000 Nm, 10000 Nm, 20000 Nm, 30000 Nm, 50000 Nm (Optional and 60000~250000N.m can be customized.)

- Output signal: 0-20mA, or with transmitter for 0-10V, 0-5V, 4-20mA, RS485 or 5~15Hz (Optional)

- Material: Alloy steel

- Power supply: 24V DC/±15V

- Current consumption: <0.2A

- Speed signal: 60 pulse/turn (≤180 pulse/turn when ≥10000 Nm)

- Torque signal: 5~15kHz

- Zero balance: 0.2% F.S.

- Non-linearity: 0.2%F.S.

- Hysteresis: 0.05% F.S.

- Repeatibilty: 0.05% F.S.

- Creep (30min): 0.05% F.S.

- Temperature effect on zero: 0.05% F.S./10℃

- Temperature drift on zero: 0.05% F.S./10℃

- Maximum speed: 15000rpm

- Response performance: 1kHz

- Impedance: 350/700±10Ω

- Insulation resistance: ≥5000MΩ/100VDC

- Annual stability: 0.3%/year

- Operating temperature: -20℃~+90℃

- Relative humidity: 0~90% RH

- Safe overload: 120%

- Maximum overload: 150%

- Cable specifications: Φ5*3

- Cable limit tension: 98N

- Weight: 10~45kg

- Warranty: 12 months

Note:

* For speed testing, the user can choose a current signal, voltage signal, or pulse signal (30 pulse/turn). For torque testing, the user may choose a current signal, voltage signal, or frequency signal (5~15kHz).

* If speed testing is needed, the user may choose the gear switch (Hall sensor) to test speed.

* Please contact us for the user manual of the rotary torque sensor and the matched digital transmitter/amplifier.

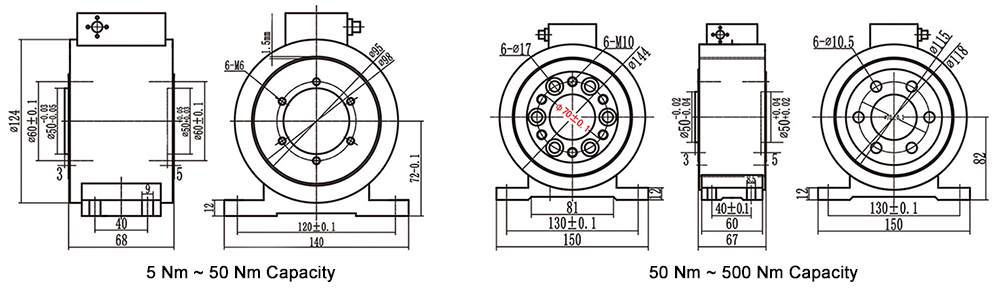

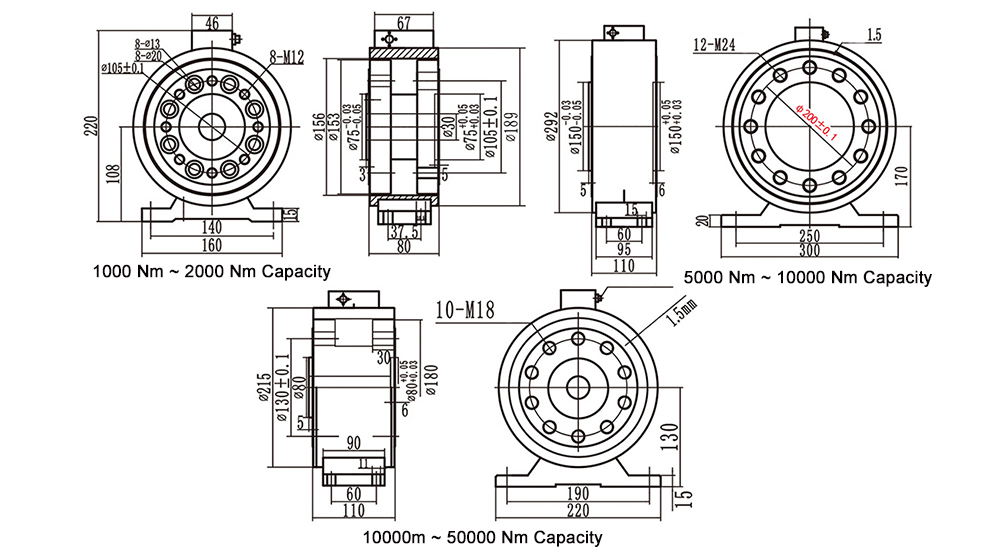

Rotary Torque Sensor Dimension (unit: mm)