Rotary Torque Sensor, Shaft to Shaft, 0 Nm-800 Nm

- Stock: In Stock

- Model: PEACO-DYN-206

- SKU: PEACO-DYN-206

$1,099.19

Ex Tax: $1,099.19

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Rotary torque sensor with shaft-to-shaft design for torque, speed, and power measurement for motor, generator, reducer, diesel engine, torque wrench, etc., comes with a matched transmitter/amplifier. There are 2 Nm, 5 Nm, 10 Nm, 50 Nm, 100 Nm, 200 Nm to 800 Nm capacity, and it outputs both forward and reverse torque signals. Instantaneous speed of the shaft torque sensor up to 3000rpm, high precision, and stable and reliable performance. With transmitter for output signal DC 4-20mA, 0-5V, 0-10V, RS485.

Rotary Torque Sensor Features- Wide range of torque sensor capacity. 2 Nm~500 Nm. 2 Nm, 5 Nm, 10 Nm, 100 Nm, 200 Nm, and 800 Nm are available for your choice.

- A transmitter to output standard signals to PLC, DCS, and other systems will be provided for the user if the user wants to obtain direct readings. The output signal can be 0~5V, 0~10V, 4-20mA, and RS485.

- Resistance strain is integrated with sensitive elements and integrated circuits, with high precision and stable and reliable performance.

- The motor torque sensor can run at high speed for a long time and output both forward and reverse torque signals.

- Both ends are key connections. The maximum speed is ≤ 3000 rpm.

- Wide applications. 1. Detect the torque in the working process of various automatic machine tools. 2. Used for electric and pneumatic torque wrenches. 3. Detect rotating power equipment, such as electric motors and internal combustion engines.

- Model: PEACO-DYN-206

- Capacity: 2 Nm, 5 Nm, 10 Nm, 20 Nm, 30 Nm, 50 Nm, 100 Nm, 200 Nm, 300Nm, 400Nm, 500Nm, etc. (Optional)

- Output Sensitivity: 1.0-1.5 mV/V

- Output signal: ±5V DC, 0~10V, 0~5V, 4~20mA, RS485 (Optional)

- Speed signal: 0~3000rpm

- Torque signal:<2.0mV/V

- Material: Stainless steel

- Zero balance: ±0.5% F.S

- Non-linearity: 0.1% F.S

- Hysteresis: 0.5% F.S.

- Repeatability: 0.05% F.S

- Creep (30min): 0.05%FS

- Temperature effect on zero: 0.05% F.S/10℃

- Temperature effect on output: 0.05% F.S/10℃

- Response frequency: 1kHz

- Annual stability: 0.3%/year

- Impedance: 700Ω

- Insulation resistance: ≥5000MΩ/100VDC

- Excitation voltage: DC 5-15V

- Operating temperature: -10℃~+60℃

- Relative humidity: 0~90%RH

- Safety overload: 150% F.S

- Maximum overload: 200% F.S

- Protection class: IP65

- Cable ultimate tension: 10kg

- Cable size: Φ5mm x 3m

- Wiring: Exc+: Red, Exc-: Black, Sig+: Green, Sig-: White

- Warranty: 12 months

Note: Please contact us for the user manual of the digital transmitter.

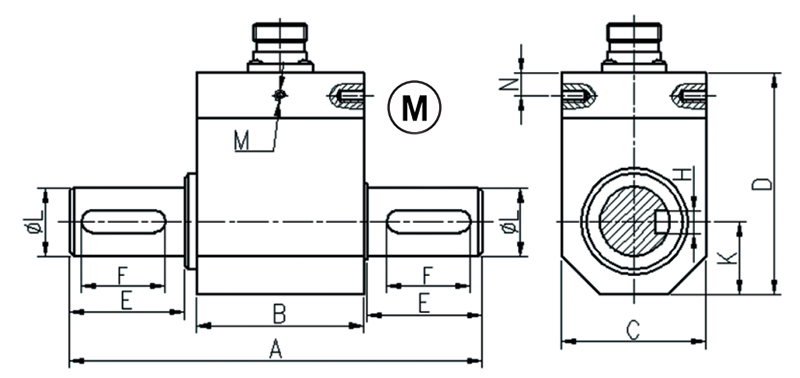

Rotary Torque Sensor Dimension (unit: mm)

| Capacity (Nm) | A | ΦL | B | C | D | E | F | K | N | M | H | Weight |

| 5/10/20 | 108 | 18 | 44 | 38 | 58 | 30 | 22 | 19 | 6 | 3-M3 | 6 | 1.5 kg |

| 30/50/100 | 108 | 18 | 44 | 38 | 58 | 30 | 22 | 19 | 6 | 3-M3 | 6 | 1.8 kg |

| 200/300 | 143 | 28 | 56 | 53 | 73.5 | 40 | 30 | 27 | 6 | 2-M3 | 8 | 2.5 kg |

| 400~800 | 188 | 38 | 70 | 78 | 96 | 56 | 40 | 39 | 7 | 5-M8 | 10 | 3.5 kg |

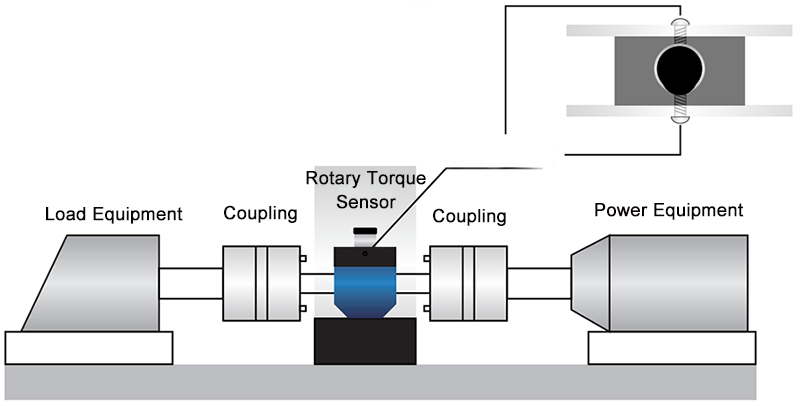

Installation Diagram

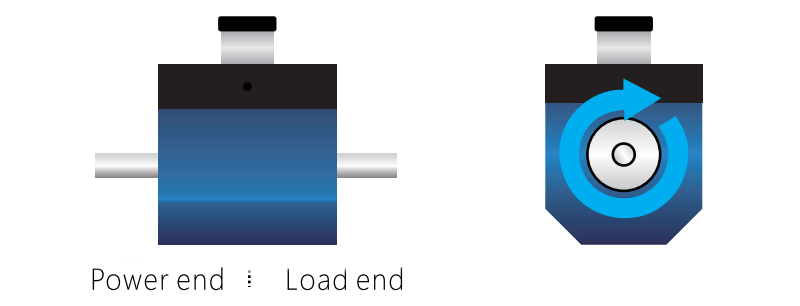

Sensor Force Diagram