70 hp VFD, Single Phase 220V Input to 3 Phase 440V Output

- Stock: In Stock

- Model: PEACO-FC280-2S/4T-55G/75P

- SKU: PEACO-STVFD-70

$3,229.57

Ex Tax: $3,229.57

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Heavy duty high quality 70 hp VFD comes with IP20 enclosed shell, 112A rated output current, converting 220V 1-phase input to 415V 3-phase output. Cost-effective variable frequency drive to provide speed control and increase the efficiency of AC electrical motors.

Our VFD are suitable for single phase and split phase input power supply.

For the 70 hp VFD user manual, please contact us.

Navigation: Motor Controls > Variable Frequency Drives >1 Phase to 3 Phase VFD > 70 hp VFD, Single Phase 220V Input to 3 Phase 440V Output

Specifications

| Basics | Model | PEACO-FC280-2S/4T-55G/75P | |

| Rated Capacity | 70 hp (55 kW) | ||

| Rated Input Current | 366A (for 220V) | ||

| Rated Output Current | 112A (for 380V) | ||

| Certification | CE | ||

| Warranty | 12 months | ||

| Applicable Motor Output | 55 kW | ||

| Power | Input Rated Voltage* | 220V±10% |

|

| Output Rated Voltage* | 220V±10%, 380V±10% |

||

| Rated Frequency | 1.0~3200Hz | ||

| Robust Design | IGBT current > 2 times of inverter output current, Capacitor > 50uF/A | ||

| PCB aging test | 100% test, 50°C, 12 hours. | ||

| Finished products aging test | 100% test, 50°C, 24 hours. | ||

| Control Feature | Control System | VF Control / Open Sensor Vector Control / Closed loop Vector (PG card - for lift/elevator) | |

| Output Frequency Resolution | 0.1Hz | ||

| Torque Characteristics | Including the auto-torque, auto-slip compensation, starting torque can be 0.5 Hz/150% (V/f), 1 Hz/150% (SVC),0 Hz/180% (FVC) | ||

| Overload Endurance | 150% / 120s, 160% / 60s, 180% / 10s, 200% / 1s | ||

| Accel / Decel Time | 0.1~65000s. (can be set individually) | ||

| Torque Boost | Automatically torque boost, manually torque boost: 0.1%~30.0% | ||

| Stall Prevention Level | 20~200%, setting of Rated Current | ||

| Operating Feature | Input / Output Terminals | Keypad | Removable |

| Input terminals | 6 multifunctional inputs, one can be work as high speed pulse Input. 3 programmable analog input: AI1, AI2, AI3: 0~10V / 4~20mA. |

||

| Output terminals | 2 Groups relay outputs, 1 open collector outputs. 2 Analog outputs, 0~10V / 4~20mA. |

||

| Communication Terminals | Build-in standard RS485 communication interface. MODBUS-RTU communication protocol. | ||

| Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | ||

| Jog Operation | Jog operation frequency: 0.0Hz~maximum frequency. Jog acceleration/deceleration time: 0.1s~3600.0s. | ||

| Other Function | AVR, S-curve, Over-Voltage Stall Prevention, DC Braking, Fault Records, Adjustable Carried Frequency, Starting Frequency Setting of DC Braking, Over-Current Stall Prevention, Momentary Power Loss Restart, Reverse Inhibition, Frequency Limits, Parameter Lock/Reset. | ||

| Protection | Over Voltage, Over Current, Under Voltage, Overload, Electronic thermal, Overheating, Self-testing. | ||

| Others | Including EMC Filter (C2/C3 Standard) | ||

| Cooling | Forced air-cooling | ||

| Installation Location | Altitude 1,000 m or below, keep from corrosive gasses, liquid and dust. | ||

| Ambient Temperature | -10°C~+40°C (Non-Condensing and not frozen) | ||

| Storage Temperature | -20°C~+60°C | ||

| Ambient Humidity | Below 90% RH (non-condensing) | ||

| Vibration | 9.80665m/s2 (1G) less than 20Hz, 5.88m/s2 (0.6Gat) 20 to 50Hz | ||

| External Accessories* |

Matched optional input EMC filter, output EMC filter, input AC reactor, output AC reactor, energy regenerated reactor, harmonic filter, sine wave filter (excluding VFD price). |

||

1. * denotes the parameters are optional or customized and please select every parameter in drop-down lists to complete your order.

2. Please contact us for external accessories catalogue and price.

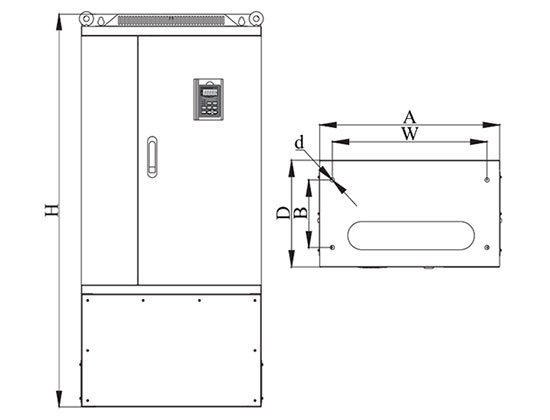

70 hp VFD Dimension (Unit: mm)

| A | H | D | W | B | Φ | Weight |

| 280 | 582 | 295 | 200 | 563 | Φ9 | 12kg |

How Variable Frequency Drive (VFD) can save energy?

The VFD reduces the output frequency, thereby reducing the motor speed. Take adjusting the air volume as an example, power consumption can be greatly reduced by reducing the air volume.

According to fluid mechanics, power = pressure × flow, the flow is proportional to the square of the speed, the pressure is proportional to the square of the speed, and the power is proportional to the cube of the speed. If the efficiency of the pump is fixed, when the regulated flow decreases, the rotational speed will decrease proportionally, and the output power will decrease in a cubic relationship. Therefore, the rotational speed of the fan and the power consumption of the motor are in an approximate cubic relationship.

For example, when a fan with a power of 55kW is adjusted to 80% of the original speed, its power consumption is 28kW/h, and the power saving rate is 48%. But if the speed is adjusted to 50% of the original, the power consumption becomes 6kw per hour, and the power saving rate reaches 87%.