- Stock: In Stock

- Model: PEACO-M4

- SKU: PEACO-SIREN-M4

Available Options

Features

- Machine stack light can be equipped with optional built-in buzzer, the volume is above 85 decibels.

- Industrial stack light adopts advanced LED color chips, features high-brightness, clear color, good light transmittance, no fading, no wear, stable performance and longer service life.

- The stack lights with buzzer feature multiple stacks design, is easy to disassemble, assemble, maintain, the body can be adjusted toward 180 degrees.

- The stack lights are widely used in automatic assembly line, automation equipment, security inspection equipment, LED packaging equipment, alarm system, SMT equipment, CNC lathe, carving machines, CNC milling machines, industrial and mining equipment, etc.

Specification

| Model | PEACO-M4 |

| Operating voltage* | AC/DC 12V, DC 24V, AC 110V, AC 120V, AC 220V 50Hz/60Hz |

| Power | 1 stack: 2W, 2 stacks: 4W, 3 stacks: 6W, 4 stacks: 8W, 5 stacks: 10W |

| Current | Single color: <50mA, Buzzer: 18mA |

| Light source | LED |

| Stack light diameter* | Φ50mm, Φ60mm, Φ70mm |

| Material of light body | ABS |

| Material of lamp housing | PC |

| Material of base | PA+15%GF |

| Material color | Black, gray, white |

| Light color | Red, yellow, green, blue, white |

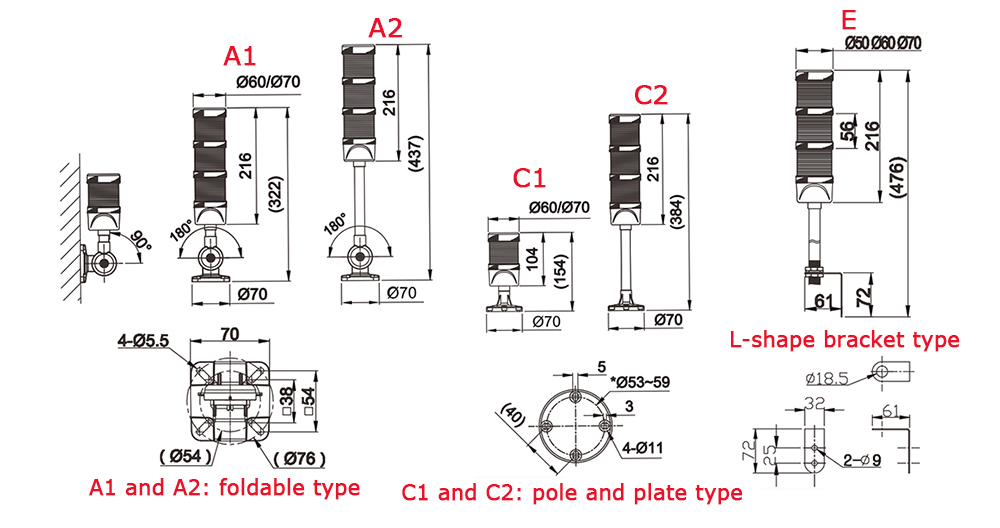

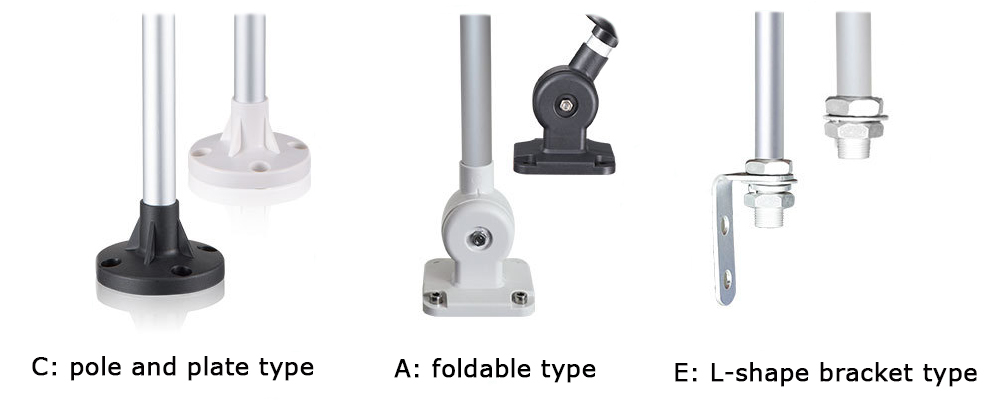

| Mounting type | A1 and A2: foldable type, C1 and C2: pole and plate type, E: L-shape bracket |

| Function* | B: steady light, F: steady light with buzzer, S: red flash light, C: red flash light with buzzer, D: All flash light, E all flash light with buzzer |

| Connect type* | T: PNP & NPN, C: contact type |

| Flash Frequency | 63-65 times/min |

| Buzzer volume | >85dB |

| Operating temperature | -20℃-45℃ |

| Protection grade | IP53 (with buzzer), IP65 (without buzzer) |

| Lifetime | 50,000 hours |

| Certification | CE |

Note: * denotes optional parameters and you can select every parameter in drop-down lists to complete your order.

Stack Light Dimension Drawing (Unit: mm)

Stack Light Wiring Diagram

LED Stack Light Applications

KNOWLEDGE BASE ---

What is stack light?

Stack light is also called machine status indicator light, signal tower light, warning light, industrial signal light or tower light. The tower stack lights are widely used on equipment in industrial manufacturing and process control environments for operator stations, call lights, machine monitoring so that they provide visual and audible indicators of a machine's status to machine operators, technicians, production managers and factory personnel. Actually, the machine stack lights identify errors in manufacturing when they happen.

LED stack light color meaning

LED stack lights are used in all kinds of machines and process environments. There are some special meaning of their color codes for machine state conditions.

- RED: Failure conditions in manufacturing, such as an emergency stop or machine fault.

- YELLOW: Warnings, such as over-temperature or over-pressure conditions.

- GREEN: Normal machine or process operation.

- BLUE: External help request, where an operator might need raw materials, scheduling or maintenance personnel assistance.

- WHITE: User-defined conditions to a specific machine, it is often related to productivity monitoring.

An optional audible alarm buzzer can be added in stack light, whose volume reaches 70–105dB typically, and stack light with buzzer can alert machine operators to pay attention to the machine conditions in auditory way more obviously.

LED stack light function

Steady light, steady light with buzzer, red flash light, red flash light with buzzer, all flash light and all flash light with buzzer.

Mounting type has foldable type, pole and plate type, L-shape bracket type.

LED stack light advantage

LEDs produce less heat than traditional light sources and have longer service life than traditional bulbs. One watt of LED power can replace the eight watts of a light bulb, making it more energy efficient during use.