- Stock: In Stock

- Model: PEACO-ASW400-2Z

- SKU: PEACO-ASW400-2Z

Available Options

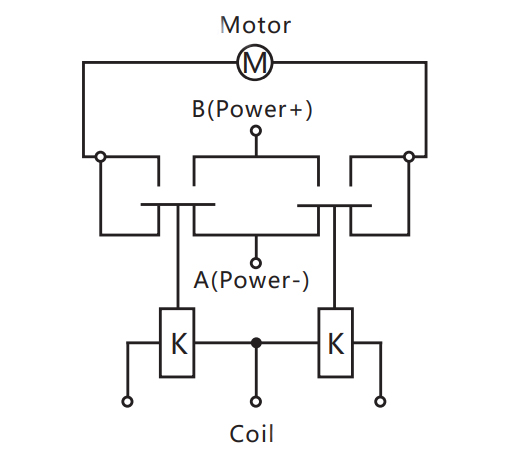

400A DC motor reversing contactor for sale, featuring continuous working duty, 2NO and 2NC (DPDT) contact form, optional magnetic blowouts, and 12V/24V/48V coil voltage or other customized coil voltage. The copper coil of the 400A DC reversing contactor has a wide range of coil suction to improve power consumption and coil life.

For a datasheet of the DC contactor, please visit Peaco Support DC contactor catalogue.pdf.

Bill of Materials (BOM)

- The upper cover of the DC reversing contactor is made of BMC material, which features high mechanical strength, good heat resistance (it can be used at 200℃ for a long time), and good aging resistance.

- DC motor reversing contactor adopts high-quality stainless steel material.

- The contact assembly uses high-quality and high-conductivity copper and silver contacts, which are reliable in contact, more durable and safer, and have an electrical life of over 30,000 times.

- The DC contactor comes with Teflon magnetic material, 500,000 movements without abrasion, temperature resistance of 155 degrees, and enameled wire.

- The base and coil frame are made of reinforced nylon PA66, which has high strength, high-temperature resistance, better flame retardancy, and electrical properties.

Applications

The DC reversing contactor has two sets of switching contacts (2NO and 2NC main contact) which are used in electric control systems, such as automotive electric winches, telecommunications equipment, construction machinery, battery cars, electric forklifts, trains, ships, uninterrupted power supplies (UPS) and other electronic control systems. Peaco Support 400A DC reversing contactor is supplied to the USA, Canada, Mexico, Europe, Africa, Asia, Australia, and New Zealand in bulk order.

Specification

| Physical Performance | Model | PEACO-ASW400-2Z | |

| Weight | 3150g | ||

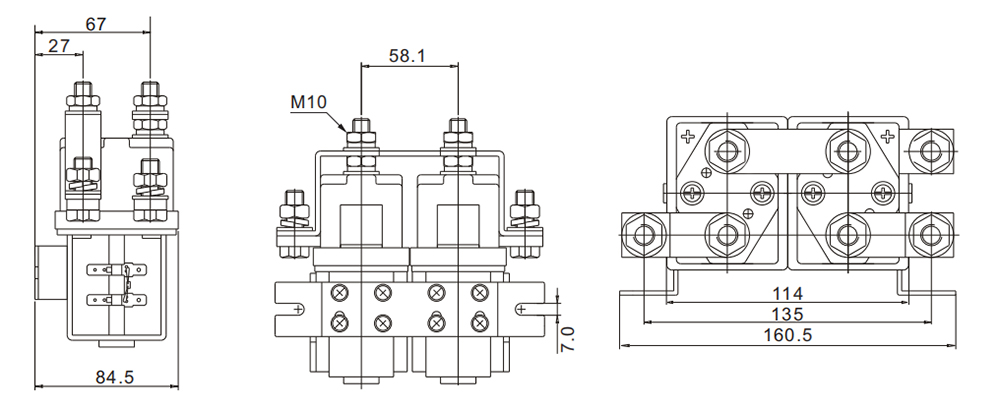

| Dimension | 51*114*160mm | ||

| Certification | CE, RoHS, ISO9001 | ||

| Warranty | 1 year | ||

| Contact Specification | Application | Continuous 400A | |

| Operation Duty | Continuous working duty | ||

| Contact Form | DPDT (2 NO and 2 NC) | ||

| Contact Load (Resistive) | 1 A-400A,12V DC-60V DC | ||

| Electrical Life (Resistive) | 20,000 times (400A 60V DC) | ||

| Max. Switching Current | ≤ 7Ie, ≤ 1s | ||

| Contact Voltage Drop | ≤ 100mV | ||

| Dielectric Withstanding Voltage | Between Coil and Contact | 50Hz/60Hz 1500V AC/1min, ≤ 1mA | |

| Between Open Contacts | 50Hz/60Hz 1500V AC/1min, ≤ 1mA | ||

| Pull-In Time | ≤ 30ms | ||

| Drop-Out Time | ≤ 20ms | ||

| Max. Contact Bounce Period | ≤ 5ms | ||

| Insulation Resistance |

≥50MΩ |

||

| Load Terminal Size | M10 External Thread | ||

| Coil Specification | Coil Type | Single Coil | |

| Rated Voltage | 12V/ 24V/ 36V/ 48/ 60V | ||

| The Allowed Range of Coil Voltage* | ±20% | ||

| Pull-In Voltage | ≤ 70% Us | ||

| Drop-Out Voltage | ≥ 5% Us, ≤ 40% Us | ||

| Coil Power | ≤ 24W | ||

| Contact Material | AgSnO/Cu or AgCuO/Cu | ||

| Mechanical Life | 200,000 times | ||

| Use of Environment | Altitude | <2 km | |

| Humidity | 5%-85% | ||

| Temperature Range | -25℃~55℃ | ||

| Protection Grade | IP50 | ||

| Vibration | 2.5G Max. Sin 5Hz-50Hz | ||

| Impact | 50g, 11ms (Half-sine wave) | ||

400A DC Reversing Contactor Dimension (Unit: mm)

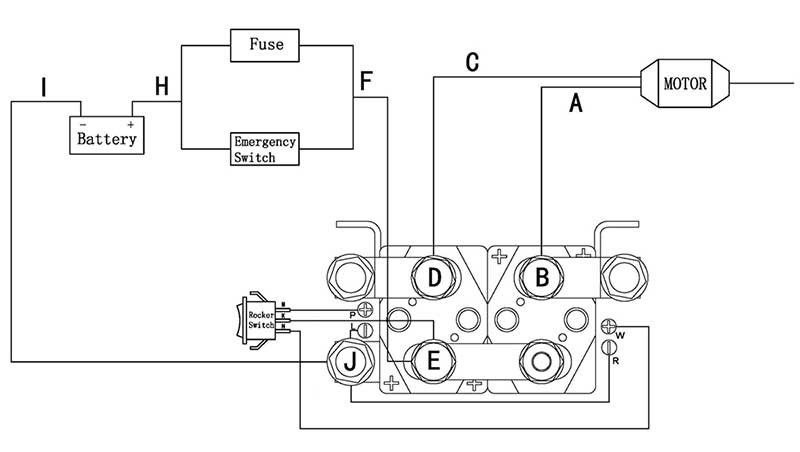

DC Reversing Contactor Wiring Diagram

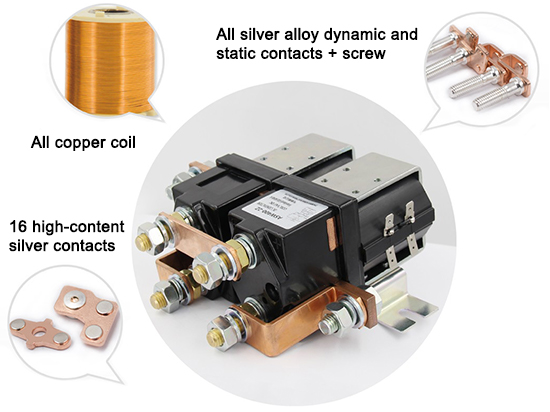

- All copper coil - Peaco Support DC motor reversing contactors adopt QA-1/155 grade enameled wire, the DC contactor coil has a wide range of suction and can be used for a long time, with low power consumption and long life.

- All silver alloy dynamic and static contacts + screw - 6 pairs of high-conductivity oxygen-free copper dynamic and static contacts and 4 silver-plated copper screws in single DC reversing contactor, low power consumption, low-temperature rise, low heat generation.

- 16 high-content silver contacts - Each DC motor reversing contactor is equipped with 16 high-content silver contacts, which have better electrical conductivity, longer life, and high-temperature resistance.

- If the AC contactor is replaced with a DC contactor and the power supply is still AC, then the DC contactor cannot be closed and the coil core will be burnt due to eddy current heating.

- If the DC contactor is replaced with an AC contactor and the power supply is still DC, then the AC contactor coil will be burnt due to excessive current.

- If the AC contactor is replaced with a DC contactor and the power supply is replaced with DC, then it can work normally.

- If the DC contactor is replaced with an AC contactor and the power supply is used with AC, then the contactor is not frequently closed and disconnected, it can be used normally. However, when the contactor is frequently switched on and off, the coil will be burnt due to frequent starting currents and excessive heat. In addition, because the arc capacity of the AC contactor is not as good as that of the DC contactor, the AC contactor also needs to be used with derating.