Custom

2 kVA Isolation Transformer, 3 Phase, 460V to 230V

- Stock: In Stock

- Model: PEACO-SG-2KVA

- SKU: PEACO-SG-2KVA

$766.97

Ex Tax: $766.97

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Small isolation transformer provides 2 kVA capacity, 50Hz/60Hz, is a 3 phase isolation transformer. Primary voltage 460V AC to secondary voltages 230V AC 3 phase step down transformer. Optional open and enclosed type for indoor and outdoor use.

Technical Parameters

- Model : PEACO-SG-2KVA

- Capacity* : 2 kVA (Customized)

- Frequency : 50Hz/60Hz

- Primary voltage (VAC)* : 120V/ 190V/ 208V/ 220V/ 230V/ 240V/ 380V/ 400V/ 440V/ 415V/ 460V/ 480V/690V...(Customized)

- Secondary voltage (VAC)* : 120V/ 190V/ 208V/ 220V/ 230V/ 240V/ 380V/ 400V/ 440V/ 415V/ 460V/ 480V/690V...(Customized)

- Withstand voltage test : 100% tested. Primary to secondary 2.5kV AC/min; Primary to safety ground 2.5kV AC/min; Secondary to safety ground 2.5kV AC/min. (does not have both puncture and break-down)

- Insulation resistance : >100MΩ / DC500V

- Insulation class : B/H

- Overload capability : 300% for 10 seconds, 150% for 120 seconds

- Efficiency : ≥ 98%

- Short circuit impedance : 4%

- Total Harmonic Distortion : ≤1%

- Power factor : 0.8

- Primary to secondary winding isolation voltage : 1000V~3000V

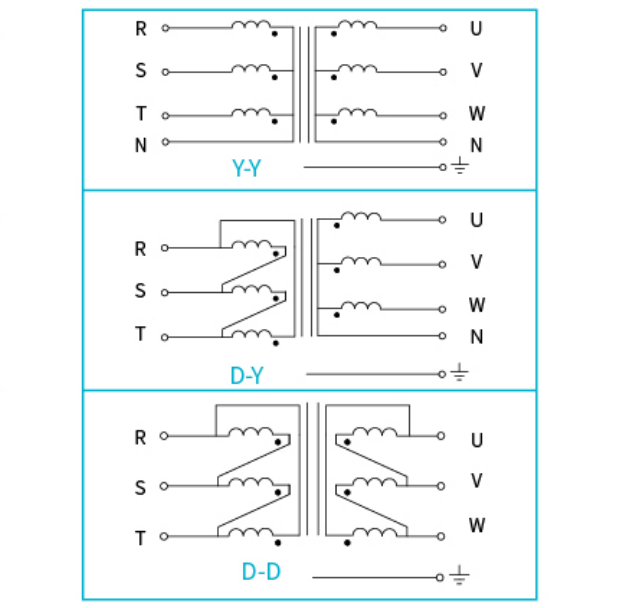

- Connection type* : standard Dyn11 and customized Ynyn0, Yd11, Dd0. Dyn5. Dzn0, etc, as per customer requriements.

- Temperature rise limit : 100K (actual temperature minus ambient temperature)

- Enclosure protection grade : standard IP22 indoor ( contact us for customized electrostatic shield or IP54, IP65 outdoor).

- Cooling mode : Natural cooling / fan system cooling

- Display* : Analogue display, digital display.

Transformer Material

- Material: Transformer coil adopts 200 degree high temperature copper or aluminum wire.

- Winding material*: 100% copper or aluminum (Optional)

Working Environment

- Noise : ≤45dB (within 1m)

- Environment temperature : -20℃~+50℃, indoor enclosure, floor-mounted

Quality Assurance

- Standard : IEC60076-1, VDE0550, IEC439, JB5555, GB5226, etc.

- Certification : CE, RoHS and ISO:9001

- Design Life : 30 years

- Warranty : 1 year

Note: * denotes optional and customized parameters and you can select every parameter in drop-down lists to complete your order. Please tell us your needed connection type.

Features

The small isolation transformer is a dry type isolation transformer. Peaco Support provides custom isolation transformer with special input and output voltages. For example, 240V to 240V isolation transformer, 440V to 230V step down transformer, 380V to 460V step up transformer, etc can be also customized. The three phase isolation transformers in Peaco Support have the following features and benefits:

- Silicon Steel Sheet: New cold rolled silicon steel sheet, 0.27mm, 0.30mm, 0.35mm of thickness, excellent performance.

- Terminal Block: High quality terminal block, excellent temperature resistance, pressure resistance and flame retardancy for small power. For high power, made of quality copper material, with good electrical conductivity, high temperature resistance, not easy to burn out the equipment when short circuit happens.

- Enameled Wires: H class enamelled copper/aluminum wires, temperature resistance 200℃, winded tightly and uniformly, no insulating layer, high heat dissipation, service life ≥35 years.

- Bobbin: The bobbion of dry type isolation transformer is made of nylon, high temperature resistance, great flame retardancy. The high power transformer with frameless design has ventilation slots between the coils for smooth air flows which reduce temperature of coils.

- Insulation Process: The whole transformer adopts H-class vacuum impregnated insulation, temperature resistance of 200°C, lower noise, better insulation and is anti-rust and anti-corrosion.

Dimension & Schematic Diagram (Unit:mm)

| Types | Dimension | Weight | |||

| Open Type (A*B*C) | Mounting Size (D*E) | Enclosed Type (A*B*C) | Open Type | Enclosed Type | |

| Aluminium Wire Transformer | 240*155*255mm | 130*115mm | 250*360*420mm | 22kg | 32kg |

| Copper Wire Transformer | 240*155*255mm | 130*130mm | 250*360*420mm | 25kg | 35kg |

KNOWLEDGE BASE --- The Importance of Silicon Steel Sheet for Transformers

- Silicon steel sheets are regarded as the primary material to form transformer core as for transformers. Silicon steel is a kind of steel that contains silicon and its silicon content ranges from 0.8% to 4.8%. Why should transformer cores be made of silicon steel? This is because silicon steel is a magnetic material with strong magnetic conductivity. It can generate a large amount of magnetic induction in current coils. Then the volume of transformer can be reduced.

- The power loss of transformer in the communication state happens not only in the resistance of coil, but also in the iron core under the magnetization of alternating current. Generally speaking, the power loss in iron core is called iron loss. The iron loss is caused by two factors: one is hysteresis loss and the other is eddy current loss. Hysteresis loss is the iron loss that occurs in the process of magnetization of iron core due to the presence of hysteresis. The magnitude of this loss is proportional to the size of the area enclosed by the hysteresis loop of the material. The hysteresis loop of silicon steel is narrow and when silicon steel is used to make transformer, the hysteresis loss of iron core is small, which can greatly reduce the heating.

- When the transformer is in operation, the magnetic flux generated by the alternating current in the coil is alternating certainly. The changing magnetic flux induces current in the iron core. The induced current generated in the iron core circulates in a plane perpendicular to the flow direction, so it is called eddy current loss, which also causes the iron core to heat up. In order to reduce the eddy current loss, the iron core of transformer is laminated with insulated silicon steel sheets. The eddy current passes through a smaller section in a long and narrow circuit to increase the electric limit of the eddy current circuit. At the same time, the silicon in the silicon steel increases the resistivity of material and also has the effect of reducing the eddy current.

- All in all, silicon steel sheet plays an important role in transformer and determines the lifespan of transformer.