Magnetic Particle Clutch, Double Shaft, 3Nm-400Nm

- Stock: In Stock

- Model: PEACO-PC

- SKU: PEACO-PC

$401.69

Ex Tax: $401.69

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Magnetic powder clutch, double shaft, wide rated torque 3Nm, 6Nm, 12Nm, 25Nm, 50Nm, 100Nm, 200Nm, 400Nm, voltage DC 24V. Uniquely suited to unwinding, rewinding, and tension control systems in printing/paper/packaging/textile / wideband cable machinery. Wide torque range, superior durability, long service life, and factory direct sale.

Please note that the base is not needed for the small torque<100 N.m and is applicable for large torque ≥ 100 N.m.

For the magnetic powder clutch and brake catalog and user manual, please visit here Peaco Support Powder Clutch and Brake Catalogue.

Features

- The excitation current has a linear relationship with the transmission torque. The torque of the magnetic powder brake is basically linear with the excitation current. The size of the control torque can be adjusted at random by changing the size of the excitation current. The torque can be controlled over a wide range. Under normal conditions, the excitation current has a linear relationship with transmission torque within the range of 5% ~ 100% rated torque.

- Stable rotational speed---the feature of torque. When the excitation current remains constant, the torque will be transmitted steadily and will not be affected by changes in speed. This feature is used in tension control, the torque can be controlled by only adjusting the excitation current to achieve the purpose of tension control.

- Effective heat sink and its load characteristics. When the friction part keeps sliding continuously, it will inevitably generate heat and even be destroyed. However, the PEACO SUPPORT magnetic powder clutch has a complete cooling device, which will not generate a lot of heat after long-term operation and has a long service life.

Specifications

| Model* PEACO- | PC-003 | PC-006 | PC-015 | PC-025 | PC-050 | PC-100 | PC-200 | PC-400 | |

| Rated Torque* (Nm) | 3 | 6 | 12 | 25 | 50 | 100 | 200 | 400 | |

| Capacity DC24V (75℃) | Current (A) | 0.53 | 0.81 | 0.94 | 1.24 | 2.15 | 2.40 | 2.70 | 3.50 |

| Power (W) | 12.7 | 19.4 | 22.5 | 30 | 51.5 | 57.6 | 64.8 | 84 | |

| Moment of Inertia | No. of Hrs Set (S) | 0.08 | 0.08 | 0.1 | 0.12 | 0.13 | 0.25 | 0.37 | 0.4 |

| Input Shaft (Kgm2) | 5.40*10-4 | 7.30*10-4 | 1.34*10-3 | 3.8*10-3 | 9.5*10-3 | 3.5*10-2 | 9.15*10-2 | 2.4*10-1 | |

| Output Shaft (Kgm2) | 2.01*10-4 | 2.40*10-4 | 4.90*10-3 | 1.49*10-3 | 4.8*10-3 | 2.5*10-2 | 6.89*10-2 | 2.2*10-1 | |

| Air Pressure (Pa) | / | 3*104 | 3*104 | 5*104 | 1*105 | 6*104 | 5*104 | 2*105 | |

| Air Volume (m³/min) | / | 0.2 | 0.2 | 0.4 | 0.6 | 1.1 | 1.6 | 2.0 | |

| Power (W) | / | 110 | 250 | 380 | 700 | 1100 | 1900 | 2800 | |

| Maximum Speed (r/min) | 1800 | ||||||||

| Weight of Powder (g) | 7.5 | 10 | 20 | 33 | 60 | 140 | 225 | 370 | |

| Item Weight (kg) | 2.5 | 2.7 | 5.2 | 9.0 | 14.5 | 37.0 | 53.0 | 100 | |

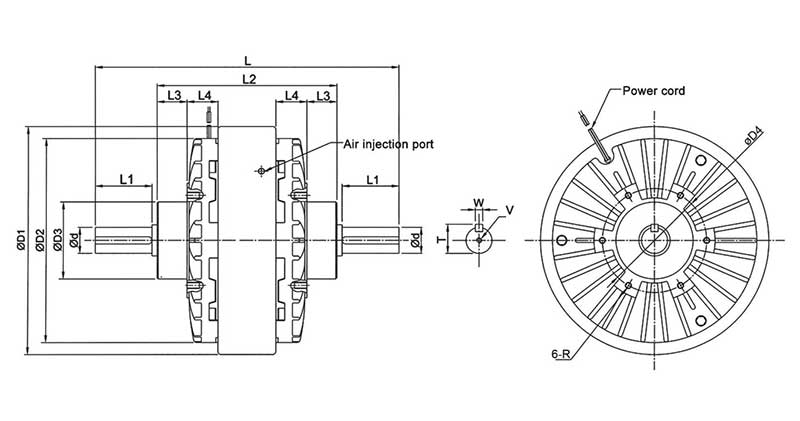

Magnetic Particle Clutch Dimension (unit: mm)

| Model* |

PC-003 |

PC-006 |

PC-015 |

PC-025 |

PC-050 |

PC-100 |

PC-200 |

PC-400 |

| D1 | 120 | 134 | 152 | 182 | 219 | 278 | 327 | 395 |

| D2 | 75 | 116 | 126 | 160 | 196 | 260 | 301 | 365 |

| D3 (g7) | 42 | 42 | 42 | 55 | 74 | 100 | 110 | 130 |

| D4 | 64 | 64 | 64 | 78 | 100 | 140 | 150 | 200 |

| L | 154 | 164 | 192 | 230 | 294 | 360 | 408 | 500 |

| L1 | 22 | 22 | 29 | 43 | 55 | 65 | 69 | 92 |

| L2 | 98 | 95 | 124 | 136 | 172 | 216 | 250 | 291 |

| L3 | 11 | 14 | 15 | 17 | 30 | 28 | 30 | 35 |

| L4 | 13.5 | 17 | 25.5 | 26 | 28 | 46 | 56 | 70 |

| d (h7) | 10 | 12 | 15 | 20 | 25 | 30 | 35 | 45 |

| T | 11.5 | 13.5 | 17 | 22 | 28 | 33 | 38.5 | 48.5 |

| W (P7) | 4 | 4 | 5 | 5 | 7 | 7 | 10 | 12 |

| V | M3*0.6P*10L | M4*0.7P*8L | M4*0.7P*8L | M5*0.8P*10L | M6*1P*12L | M10*1.5P*20L | M10*1.5P*20L | M10*1.5P*20L |

| R | 6-M5*0.8P*10L | 6-M6*1P*10L | 6-M6*1P*10L | 6-M6*1P*10L | 6-M6*1P*10L | 6-M10*1.5P*20L | 6-M10*1.5P*20L | 8-M10*1.5P*15L |

| S | / | 1/8 | 1/8 | 1/8 | 1/4 | 3/8 | 3/8 | 3/8 |

Magnetic Particle Clutch Application

Magnetic Particle Brake Package

KNOWLEDGE BASE --- Magnetic Particle Clutch Applications

- For buffer start and stop. The magnetic particle clutch has smooth and constant torque to buffer when a connection occurs. In other words, the clutch has stable acceleration and torque.

- For continuous sliding and tension control.

- For high-speed response.

- For simulated load.

- For power absorption.

- For positioning and stopping.

- For torque limiter.

- It can be used for clutching and torque braking in the process of torque transmission.

- Magnetic particle clutch is suitable for constant tension control systems, such as printing machines, slitting machines, laminating machines, coating machines, paper machines, wire drawing machines, and cable winding machines, as well as metal sheet, strip, film, and other processing equipment and textile machinery, etc.

- The magnetic powder clutches can replace ordinary clutches, widely used in machine tools for rapid separation and numerical control devices, computers, wide-line printers, and other precision machinery.

- In overload protection, when the working system has an accident and the torque is overloaded, the clutch will automatically slip to protect the mechanical equipment and the driving force.

- For stepless speed regulation. Equipped with sensors and control circuits, the clutch can realize stepless speed regulation, especially for fine-tuning the speed at high speed and the speed regulation system of medium and small power.

- Can be used as an overload device. magnetic powder clutch can be applied to hoisting machinery, and cement/ steel mechanical equipment. It can start the prime mover without load, load it gradually, and improve the load capacity of the equipment.