- Stock: In Stock

- Model: PEACO-SGG-8KVA

- SKU: PEACO-K3PIT-8KVA

Available Options

Technical Parameters

- Model: PEACO-SGG-8KVA

- Capacity*: 8 kVA (Customized)

- Frequency : 50Hz/60Hz

- Primary voltage (VAC)* : 120V/ 190V/ 208V/ 220V/ 230V/ 240V/ 380V/ 400V/ 440V/ 415V/ 460V/ 480V/690V...(Customized)

- Secondary voltage (VAC)* : 120V/ 190V/ 208V/ 220V/ 230V/ 240V/ 380V/ 400V/ 440V/ 415V/ 460V/ 480V/690V...(Customized)

- Withstand voltage test: 100% tested. Primary to secondary 2.5kV AC/min; Primary to safety ground 2.5kV AC/min; Secondary to safety ground 2.5kV AC/min. (does not have both puncture and break-down)

- Insulation resistance : >100MΩ / DC500V

- Insulation class: H

- Overload capability: 300% for 10 seconds, 150% for 120 seconds

- Efficiency : ≥98%

- Short circuit impedance: 4%

- Total Harmonic Distortion: ≤1%

- Power factor: 0.8

- Primary to secondary winding isolation voltage: 1000V~3000V

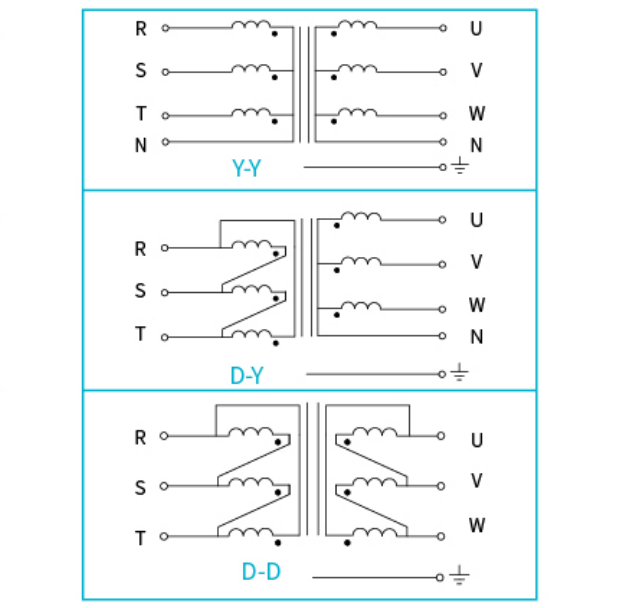

- Connection type* : standard Dyn11 and customized Ynyn0, Yd11, Dd0. Dyn5. Dzn0, etc, as per customer requirements.

- Temperature rise limit: 100K (actual temperature minus ambient temperature)

- Enclosure protection grade*: standard IP22 indoor (contact us for customized electrostatic shield or IP54 outdoor).

- Cooling mode: Natural cooling/fan system cooling

- K factor: Standard K4 (contact us for customization)

- Display*: Analogue display, digital display.

Transformer Material

- Material: Transformer coil adopts 200-degree high-temperature copper or aluminum wire.

- Winding material*: 100% copper or aluminum (Optional)

- Insulation Class: H Class

Working Environment

- Noise: ≤ 60dB (within 1m)

- Environment temperature : -20℃~+50℃, indoor enclosure, floor-mounted

- Insulation Class: H Class

Quality Assurance

- Standard : IEC60076-1, VDE0550, IEC439, JB5555, GB5226, etc.

- Certification: CE, RoHS, and ISO:9001

- Design Life: 30 years

- Warranty: 1 year

- * Denotes optional and customized parameters; you can select every parameter in drop-down lists to complete your order.

- 8 kVA transformer is not a phase converter. It is usable for three-phase step-up or three-phase-step-down voltage.

- The transformer is unsuitable for converting any frequency from 50 Hz to 60 Hz or 60 Hz to 50 Hz. It can function either input and output 50 hz or 60 hz frequency.

- Silicon Steel Sheet

A New cold-rolled silicon steel sheet, 0.27mm, 0.30mm, 0.35mm of thickness, excellent performance.

- Terminal Block

High-quality terminal block, excellent temperature resistance, pressure resistance, and flame retardancy for small power. For high power, made of quality copper material, with good electrical conductivity, and high-temperature resistance, and hard to burn out the equipment when a short circuit happens.

- Enameled Wires

H class enameled copper/aluminum wires, temperature resistance 180℃, winded tightly and uniformly, no insulating layer, high heat dissipation, service life ≥35 years.

- Bobbin

The 3-phase isolation transformer is made of nylon, with high-temperature resistance, and great flame retardancy. The high-power transformer with a frameless design has ventilation slots between the coils for smooth airflow, which reduces the temperature of the coils.

- Insulation Process

The whole dry-type isolation transformer adopts H-class vacuum-impregnated insulation, temperature resistance of 200°C, lower noise, better insulation, and anti-rust and anti-corrosion.

| Types | Dimension | Weight | ||

| Open Type (A*B*C) | Enclosed Type (A*B*C) | Open Type | Enclosed Type | |

| Aluminum Wire Transformer | 280*200*260mm | 430*320*400mm | 63kg | 77kg |

| Copper Wire Transformer | 280*200*260mm | 430*320*400mm | 68kg | 82kg |