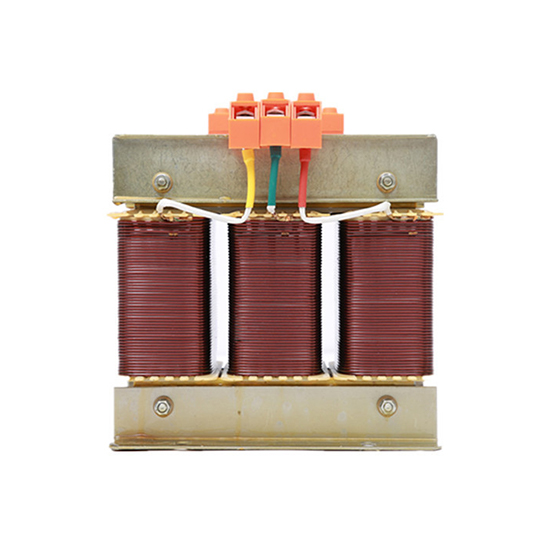

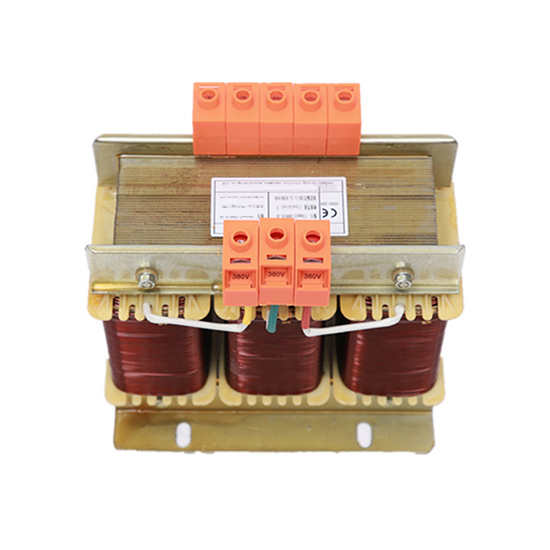

5 kVA Control Transformer, 3 Phase, 220V to 400V

- Stock: In Stock

- Model: PEACO-SBK-5kVA

- SKU: PEACO-SBK-CT-5k

$1,854.85

Ex Tax: $1,854.85

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

5 kVA three phase control transformer features optional Enameled pure copper or aluminum wire, a wide selection of primary voltage and secondary voltage, H class enameled wires, vacuum impregnated insulation. Cost-effective step-up / step-down transformer used in servo motors, CNC machine tools, testing machines, winding machines, packaging machinery, printing machinery, textile equipment, automated production lines, etc.

Specification

| Model | PEACO-SBK-5kVA |

||

| Winding Material* | Enameled copper wire or enameled aluminum wire (Optional) | ||

| Capacity* | 5kVA (Customized) | ||

| Primary Voltage (VAC)* | 110, 120, 208, 220, 230, 240, 380, 400, 440, 460, 480, 110/220, 120/240, 240/480, 600...(Customized) | ||

| Secondary Voltage (VAC)* | 110, 120, 208, 220, 230, 240, 380, 400, 440, 460, 480, 110/220, 120/240, 240/480, 600...(Customized) |

||

| Withstand Voltage Test | Primary to secondary 2.5KV/min; Primary to safety ground 2.5KV/min; Secondary to safety ground 1.5KV/min. | ||

| Insulation Resistance | Primary to secondary 2500V>100 megohm; Primary to safety ground 2500V>100 megohm; Secondary to safety ground 1500V>100 megohm. | ||

| Frequency* | 50 / 60Hz | Insulation Level | F / H |

| Induction Withstand Voltage Test | 125Hz/ 800V/min | Ground Resistance | 25A < 80 milliohm |

| Cooling Method | Natural or air cooling | Transformation Ratio | < 3% |

| No-load Current | < 3% | Impedance Voltage | About 4.5% |

| Total Losses / Efficiency | 4% / 80%~99% | Operating Temperature | -15℃~40℃ (40℃, 90% RH, 56 days) |

| Noise | ≤35~65dB (A)(within 1 metre) | Storage Temperature | -25℃~100℃ (40℃, 90% RH, 56 days) |

| Certificate | CE, ISO | Designed Life | 30 years |

| Warranty | 1 year | Weight | 50.0 kg for open type / 60.0kg for enclosed type |

| Overall Size (A*B*C) | 300*170*310mm / 300*440*500mm |

Installation Dimension (D*E) | 180*140mm |

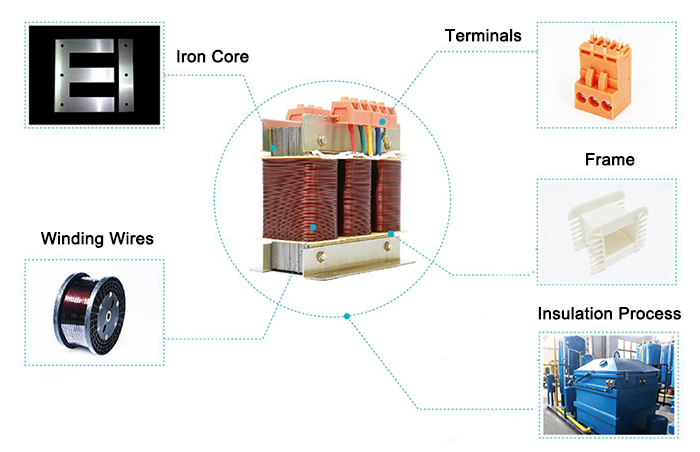

Control Transformer Features

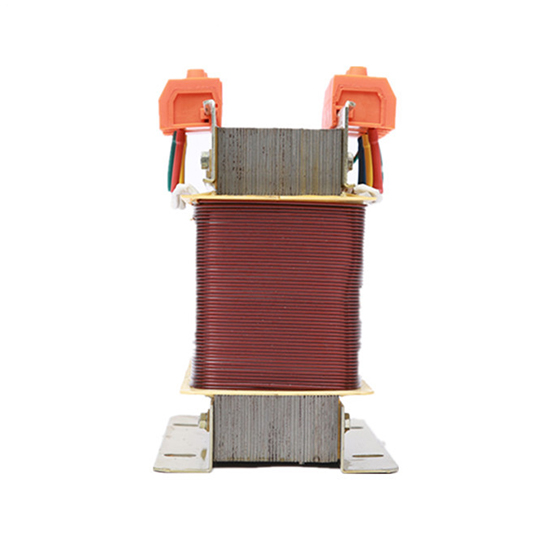

1. Iron Core

The transformer iron core thickness is flexible, 0.27mm, 0.30mm, 0.35m, H18, H14, H12, Z11 are available. Brand new and high quality cold-rolled silicon steel sheets are used to produce. Other material is also available according to customer requirements.

2. Terminals

Features excellent temperature resistance, pressure resistance, flame retardancy, Both low and high power control transformers adopt high-quality pure copper.

3. Frame

Made of nylon with high temperature resistance, great flame retardancy. The high-power transformers come with frameless design and there are ventilation slots between the coils so that the air flows smoothly, which can reduce the temperature of coils quickly and effectively.

4. Winding Wires

Control transformer winding is made of H-class enameled copper or aluminum, featuring 180°C temperature resistance and they are arranged tightly and uniformly. The outer surface is not wraped with an insulating layer, which has high heat dissipation.

5. Insulation Process

The whole transformer adopts H-class insulating paint under vacuum pressure, temperature resistance of 180°C, low operation noise and good insulation performance and is anti-rust and anti-corrosion.

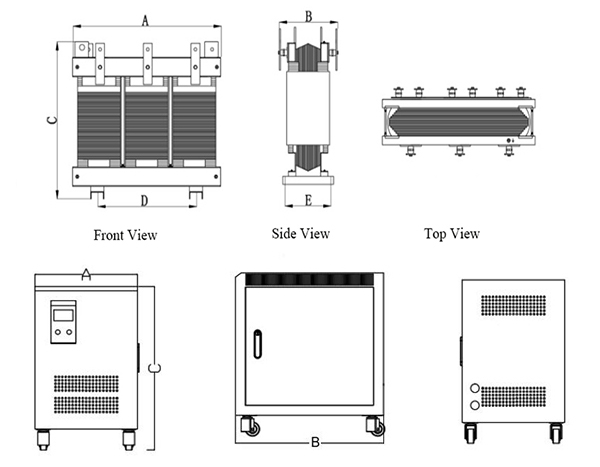

Control Transformer Dimension

| Capacity | Dimension | Weight | |||

| Open Type (A*B*C) | Mounting Size (D*E) | Enclosed Type (A*B*C) | Open Type | Enclosed Type | |

| 5 kVA | 300*170*310mm | 180*140mm | 300*440*500mm | 50kg | 60kg |

Control Transformer Schematic Diagram

KNOWLEDGE BASE --- Purpose of Control Transformer in Machine Control Systems

Control transformers are also known as machine tool transformers, industrial control transformers or control power transformers.

The control transformer can isolate electric to prevent electric shock, is convenient to obtain the appropriate voltage and features anti-interference function.

Control transformer is usually used in machine tools and mechanical equipment as electrical control lighting and indicator lights power supply. The control transformer occupies a very important position in the power transmission and distribution system and it is required to operate safely and reliably. When the control transformer is damaged in operation, it will cause a power outage. Therefore, the control transformer is a very important electrical equipment.

The control transformer is mainly suitable for AC 50H or 60Hz, circuits (≤1000V) and can work continuously for a long time under rated load and is typically used in industrial applications.