- Stock: In Stock

- Model: PEACO-D5BLD300-30S

- SKU: PEACO-BLDC-300W

Available Options

3-phase brushless DC motor comes with 300W power, 0.96 high torque, 3000 rpm speed, 12V/24V/36V/48V DC rated voltage. High torque brushless DC motor works even in harsh environments. The 24VDC brake, brushless motor speed controller, and planetary/ worm gearbox are optional for your needs. Customized brushless motor length, shaft, speed, voltage, power, and lead are available.

Features

- The BLDC motor has three motor wires, and five Hall wires that work well with a brushless DC motor controller, which has high performance for good control. Easy for speed adjustment and reversible direction.

- The brushless direct current motor can be equipped with a planetary gearbox/worm gearbox for effective speed control and increasing torque for your needs. The gear ratio is up to 4:1-250: 1 for options.

- The 3-phase brushless DC motor has no brushes and no sparks will be generated during operation, which greatly reduces friction. Smoother running, longer service life. No need for cleaning and maintenance.

- The brushless DC electric motor is a 3-phase motor with higher efficiency, low heat loss, lower emissions, lower EMI/RFI, and high C/P.

- The electric motor comes with a smaller size, compact, and less-weight design. Users can connect to the PLC to read the speed parameters, etc.

- Peaco Support brushless DC motors have high-quality housing that can be used in various harsh environments of -20~55℃ and are often used in modern devices where low noise and continuous low heat are required, such as washing machines, air conditioners, service robots, and other consumer electronics.

Specification

| Model | PEACO-D5BLD300-30S | |||

| Power | 300W | |||

| Voltage* | 12V | 24V | 36V | 48V |

| Rated current | 31.25A | 15.63A | 10.42A | 7.81A |

| No-load current | <7.2A | <6.13A | <3.5A | <4.61A |

| No-load speed | 3300rpm | |||

| Rated speed | 3000 rpm | |||

| Rated torque | 0.96 Nm | |||

| Peak torque | 2.87 Nm | |||

| Square flange size | 86*86 mm | |||

| Phase | 3 phase | |||

| Motor lead length | 100cm | |||

| Protection grade | IP54 | |||

| Insulation rank | F | |||

| Certification | CE, RoHS, ISO/TS16949 | |||

| Warranty | 1 year | |||

| Weight | 3.5kg | |||

| Other optional accessories* | Matched brake, planetary gearbox or worm gearbox, controller | |||

Notes:

1. * denotes optional or customized parameters; you can select every parameter in drop-down lists to complete your order.

2. Motor length, shaft, speed, voltage, power, keyway, lead, and controller can be customized for your needs.

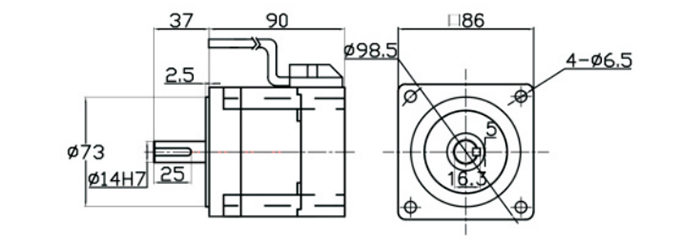

Brushless DC Motor Dimension (Unit: mm)

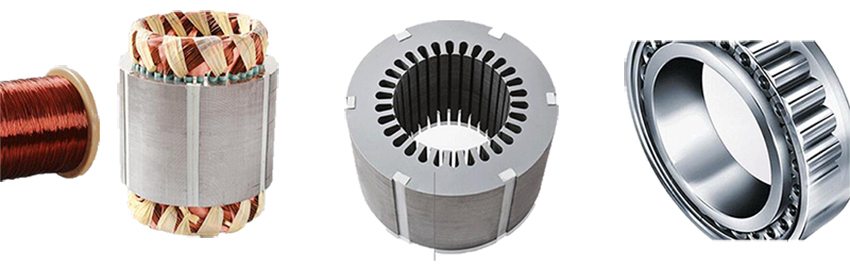

- The brushless dc motor adopts full pure copper, which is the best source of power, high performance, and longer span life.

- A brushless DC electric motor is made of cold rolled silicon sand steel sheet, which has good toughness, endurance, and wear resistance.

- High torque brushless motor adopts high strength fine steel die casting to achieve long life, low friction coefficient, and high flexibility joints.

- The casting material of the 3-phase brushless DC motor is harder than the ordinary housing and features better heat dissipation and strong and durable housing.

Wiring Diagram

| Power Wire | Hall Wire | ||||||

| Red | Yellow | Black | Red | Black | Hu | Hv | Hw |

| U | V | W | 5V | GND | Blue | Green | White |

300W BLDC planetary gear motor has the advantages of smooth working and high efficiency, featuring a wide range of gear ratios for different requirements. The length, shaft, input voltage, key size etc. can be customized for BLDC motor with desired planetary gearbox as per customer's different needs.

Planetary Gearbox Features

1. The output shaft of the double support structure greatly improves the bearing torque of the planetary gearbox.

2. The wheel and the planet frame are splined, which greatly enhances the internal gearbox bear torque, and improves the service life of the BLDC motor.

3. The helical teeth are adopted in the part that is connected with the motor, which makes the gearbox transmission more stable and the noise is lower under the condition of high speed. The inner gear part of the gearbox adopts a segmented structure, which makes the speed ratio distribution of the gearbox wider and the structure design of the whole motor more flexible. The connection between the gearbox and the motor adopts the spigot positioning, and the axial locking screw makes the brushless DC motor with a planetary gearbox more precise and the noise is low.

4. Double support structure of output shaft and first-stage helical tooth scheme is adopted, the inner hole grinding process of planetary gear makes the inner hole roundness less than 0.003mm and the tooth surface hardness is HRC60 degree precision scraping. The adoption of this series of processes enables the gearbox to have a smooth operation, making its life span more than 10,000 hours.

5. The needle roller cage is used in the planetary gear and the sliding friction is replaced by rolling friction so that the life of the gearbox is longer.

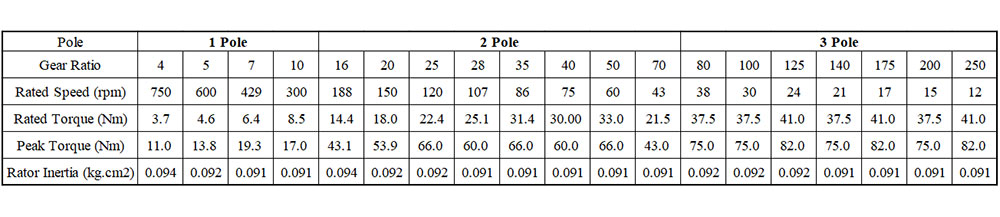

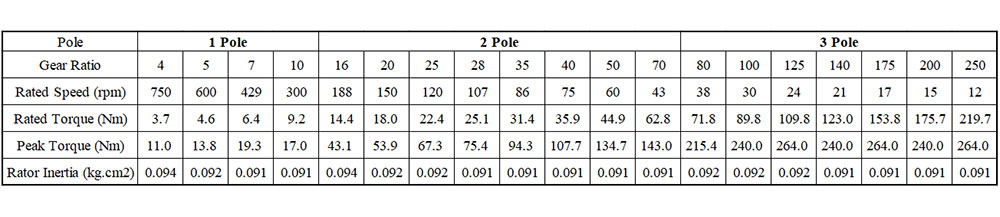

Allowable Torque with Planetary Gearbox (PLF-060 Type)

Note: Please add the gear ratio in the Comment section of the Checkout page while checking out the product.

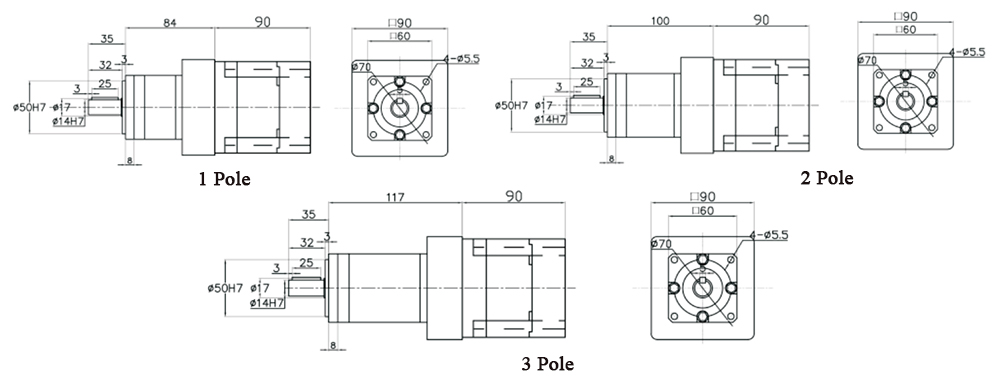

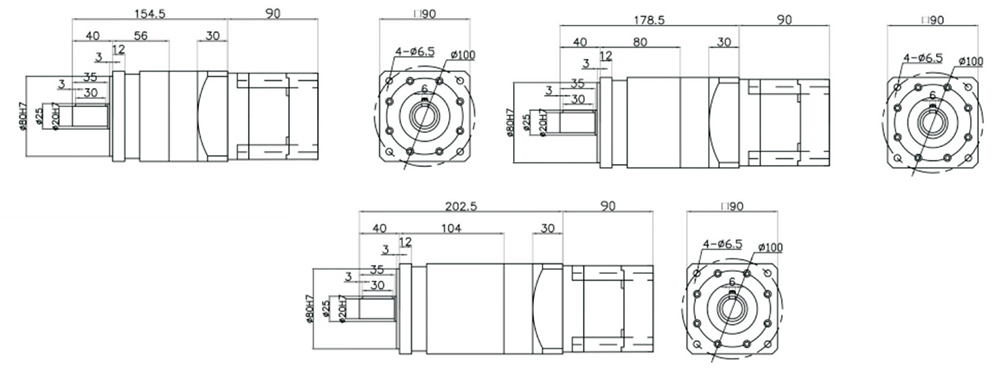

BLDC Motor with Planetary Gearbox Dimension (Unit: mm)

Allowable Torque with Planetary Gearbox (PLF-090 Type)

Note: Please add the gear ratio in the Comment section of the Checkout page while checking out the product.

BLDC Motor with Planetary Gearbox Dimension (Unit: mm)

BLDC Motor Specification:

| Motor Model | Power | Voltage | No-load Current | Rated Speed | Rated Current | Rated Torque | Max. Torque | No-load Current |

| D5BLD300-12A-20S | 300W | 12V | 2700 rpm | 2000 rpm | 31.25A | 1.43N.m | 4.30N.m | <7.20A |

| D5BLD300-24A-20S | 300W | 24V | 2700 rpm | 2000 rpm | 15.63A | 1.43N.m | 4.30N.m | <6.13A |

| D5BLD300-36A-20S | 300W | 36V | 2700 rpm | 2000 rpm | 10.42A | 1.43N.m | 4.30N.m | <3.50A |

| D5BLD300-48A-20S | 300W | 48V | 2700 rpm | 2000 rpm | 7.81A | 1.43N.m | 4.30N.m | <4.61A |

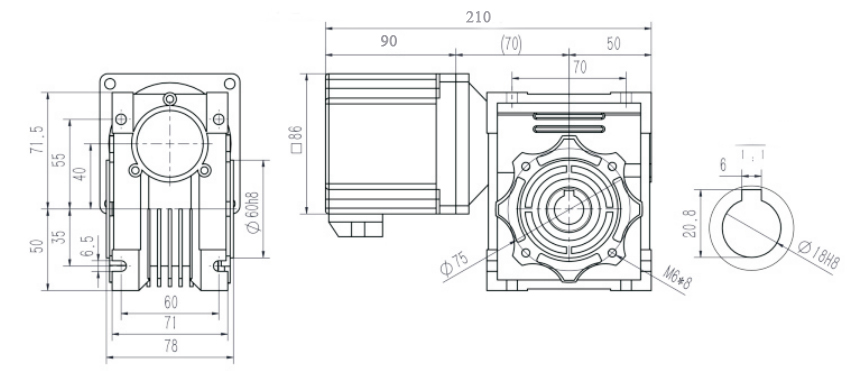

Allowable Torque with Worm Gearbox

RV040 Type:

| Gear Ratio | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 |

| Rated Output Speed (rpm) | 267 | 200 | 133 | 100 | 80 | 67 | 50 | 40 | 33 | 25 | 20 |

| Rated Output Torque (Nm) | 4.3 | 5.76 | 8.64 | 11.52 | 14.4 | 17.28 | 23 | 28.8 | 34.6 | 33.0 | 39.0 |

Note:

1. The speed is calculated based on the rated speed of the motor divided by the reduction ratio. The actual speed will vary with the size of the load and will be reduced by about 2%-20% from the shown value. The rated speed of the brushless DC motor is 2000rpm and the no-load speed is 2800rpm when it is matched with a worm gearbox.

2. Please add the gear ratio in the Comment section of the Checkout page while checking out the product.