- Stock: In Stock

- Model: PEACO-D2BLD150-30S

- SKU: PEACO-BLDC-150W

Available Options

150W brushless DC electric (BLDC) motor runs at 3000 rpm speed, 12V/24V/36V/48V DC rated voltage, torque 0.48Nm, and peak torque 1.43 Nm respectively. High torque brushless DC motor matched with brushless motor speed controller and gearbox, high efficiency of 85-90%, and excellent controllability, is widely used in modern production equipment, instruments, meters, and advanced household appliances.

Features

- The BLDC motor has three motor wires and Hall wires and works well with a brushless DC motor controller, which has high performance for good control. Easy for speed adjustment and reversible direction.

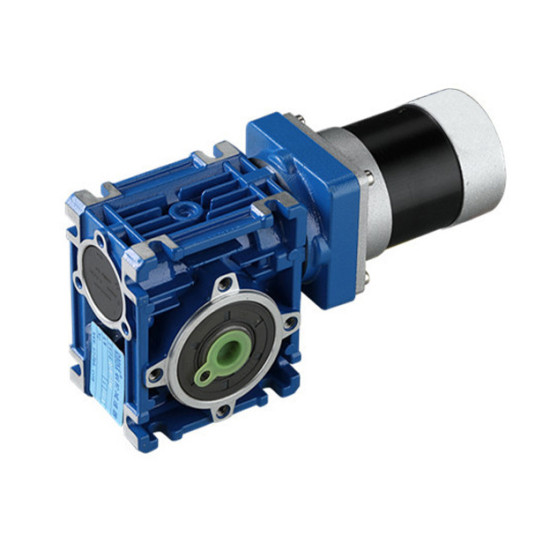

- The brushless DC motor can be equipped with a planetary gearbox/worm gearbox for effective speed control and increasing torque for your needs. The gear ratio is up to 4:1-250: 1 for options.

- The 3-phase brushless DC motor has no brushes and no sparks will be generated during operation, which greatly reduces friction. Smoother running, longer service life. No need for cleaning and maintenance.

- The brushless DC electric motor is a 3-phase motor with higher efficiency, low heat loss, lower emissions, lower EMI/RFI, and high C/P.

- The electric motor comes with a smaller size, compact, and less-weight design. Users can connect to the PLC to read the speed parameters, etc.

- Brushless DC motors are often used in modern devices where low noise, low heat, and compact size are required, such as washing machines, air conditioners, AGVs, service robots, and other consumer electronics.

Specification

| Model | PEACO-D2BLD150-30S | ||||

| Power | 150W | ||||

| Rated Voltage* | 12V | 24V | 36V | 48V | 310V |

| Rated current | 15.63A | 7.81A | 5.21A | 3.91A | 0.60A |

| No-load current | <1.5A | <1.0A | <0.8A | <0.6A | <0.4A |

| No-load speed | 3300rpm | ||||

| Rated speed | 3000 rpm | ||||

| Rated torque | 0.48 Nm | ||||

| Peak torque | 1.43 Nm | ||||

| Square flange size | 60mm | ||||

| Phase | 3 phase | ||||

| Motor lead length | 100cm | ||||

| Protection grade | IP54 | ||||

| Insulation rank | F | ||||

| Certification | CE, RoHS, ISO/TS16949 | ||||

| Warranty | 1 year | ||||

| Weight | 2.8kg | ||||

| Other optional accessories* | Matched brake, planetary gearbox or worm gearbox, controller | ||||

Notes:

1. * denotes optional or customized parameters; you can select every parameter in drop-down lists to complete your order.

2. 150W BLDC Motor length, shaft, keyway, speed, voltage, power, lead, and controller can be customized for your needs.

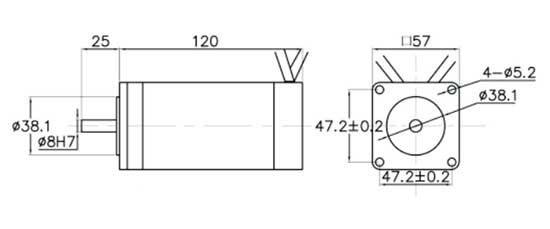

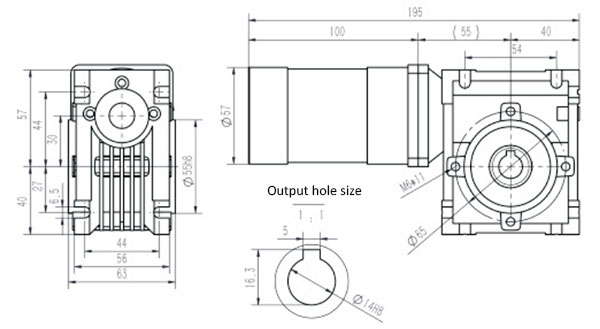

Brushless DC Motor Dimension (Unit: mm)

Wiring Diagram

| Power Wire | Hall Wire | ||||||

| Red | Yellow | Black | Red | Black | Hu | Hv | Hw |

| U | V | W | 5V | GND | Blue | Green | White |

What are the advantages of brushless DC motors?

- High efficiency. The efficiency of general brushless DC motors can reach more than 96%, while other traditional DC motors generally are up to around 75%. If their efficiency is high, then the mechanical energy for converting electrical energy into the motor will be high with high energy conversion. In other words, BLDC motors are 20% more energy-saving than brushed motors. For example, if a brushless DC motor runs for a long time, it can save the electricity cost of a motor every year.

- Long service life. Generally speaking, traditional brushed motors have to be replaced frequently due to the wear of the carbon brushes. However, brushless DC motors generally have a service life of more than 20,000 hours under normal working conditions. After they are used for more than 5 years, they will not be damaged basically. Therefore, the service life of brushless DC motors is 5 times that of traditional brushed motors.

- Low noise. Because the brushless DC electric motor provides a simple structure, it runs relatively smoothly and the operating sound is below 50dB with quiet performance. Therefore, brushless DC motors are widely used in many medical equipment. However, conventional motors require the replacement of carbon brushes, which cannot be sealed. What's more, the wear of the carbon brush causes frictional noise, which is generally up to above 60 dB. Thus, in this case, such a traditional motor can not meet the requirements where low noise is required.

150W brushless DC planetary gear motor provides high performance and high working efficiency, featuring a wide range of gear ratios from 4:1 to 250:1. BLDC motor length, shaft, keyway, etc. can be customized according to the customer's need.

Planetary Gearbox Features

1. The output shaft of the double support structure greatly improves the bearing torque of the gearbox.

2. The wheel and the planet frame are splined, which greatly enhances the internal gearbox bear torque, and improves the service life of the BLDC motor.

3. The helical teeth are adopted in the part that is connected with the motor, which makes the gearbox transmission more stable and the noise is lower under the condition of high speed. The inner gear part of the gearbox adopts a segmented structure, which makes the speed ratio distribution of the gearbox wider and the structure design of the whole motor more flexible. The connection between the gearbox and the motor adopts the spigot positioning, and the axial locking screw makes the brushless DC motor with a planetary gearbox more precise and the noise is low.

4. Double support structure of output shaft and first-stage helical tooth scheme is adopted, the inner hole grinding process of planetary gear makes the inner hole roundness less than 0.003mm and the tooth surface hardness is HRC60 degree precision scraping. The adoption of this series of processes enables the gearbox to have a smooth operation, making its life span more than 10,000 hours.

5. The needle roller cage is used in the planetary gear and the sliding friction is replaced by rolling friction so that the life of the gearbox is longer.

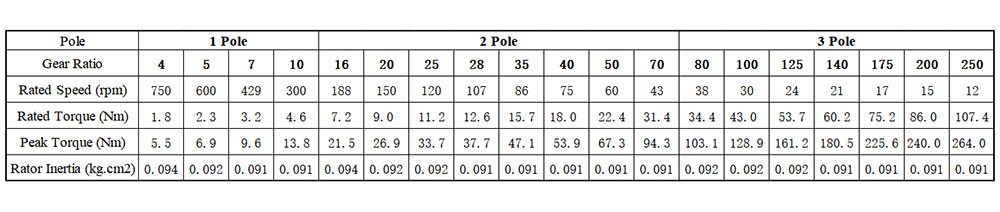

Allowable Torque with Planetary Gearbox (PLF-060 Type)

Note: Please add the gear ratio in the Comment section of the Checkout page while checking out the product.

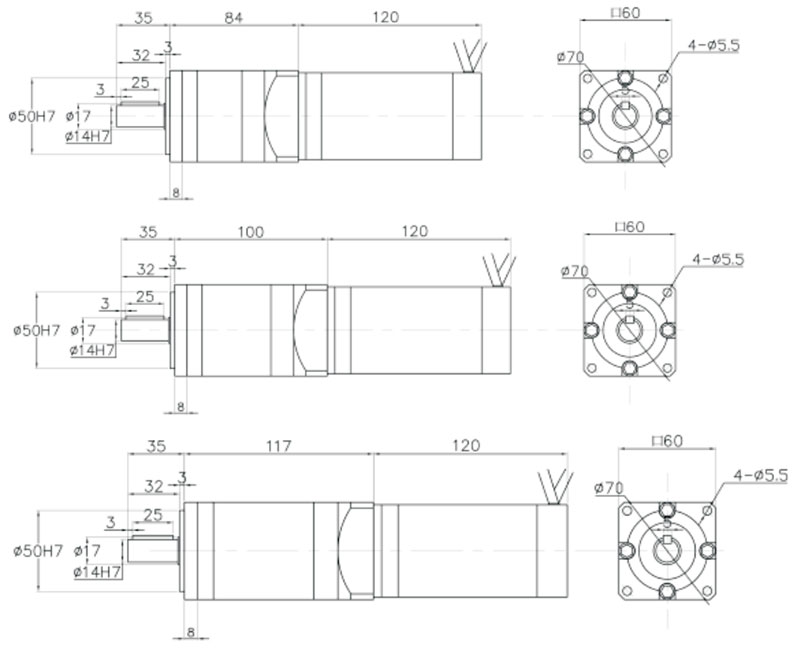

BLDC Motor with Planetary Gearbox Dimension (Unit: mm)

BLDC Motor Specification:

| Motor Model | Power | Voltage | No-load Current | Rated Speed | Rated Current | Rated Torque | Max. Torque | No-load Current |

| D2BLD150-12GN-20S | 150W | 12V | 2800 rpm | 2000 rpm | 15.63A | 0.72N.m | 2.15N.m | <1.50A |

| D2BLD150-24GN-20S | 150W | 24V | 2800 rpm | 2000 rpm | 7.81A | 0.72N.m | 2.15N.m | <1.0A |

| D2BLD150-36GN-20S | 150W | 36V | 2800 rpm | 2000 rpm | 5.21A | 0.72N.m | 2.15N.m | <0.8A |

| D2BLD150-48GN-20S | 150W | 48V | 2800 rpm | 2000 rpm | 3.91A | 0.72N.m | 2.15N.m | <0.6A |

Allowable Torque with Worm Gearbox

RV030 Type:

| Gear Ratio | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 |

| Rated Output Speed (rpm) | 267 | 200 | 133 | 100 | 80 | 67 | 50 | 40 | 33 | 25 |

| Rated Output Torque (Nm) | 4.3 | 5.7 | 8.6 | 11.2 | 13.6 | 15.9 | 17.0 | 12.0 | 17.0 | 12.0 |

Note:

1. The speed is calculated based on the rated speed of the motor divided by the reduction ratio. The actual speed will vary with the size of the load and will be reduced by about 2%-20% from the shown value. The rated speed of the brushless DC motor is 2000rpm and the no-load speed is 2800rpm when it is matched with a worm gearbox.

2. Please add the gear ratio in the Comment section of the Checkout page while checking out the product.