- Stock: In Stock

- Model: PEACO-LZZH-2

- SKU: PEACO-FL-2

Available Options

The variable area flowmeter comes with a square pointer indicator, vertical thread connection can be produced according to the diameter and customer requirements. Nominal diameter up to DN15mm-DN150mm with no output and with 4-20mA output to choose. The metal tube variable area flowmeter adopts metal structure, suitable for high temperature, high pressure and strong corrosive medium.

Features

1. M7 pointer indicates 4-20mA remote transmission and mechanical upper and lower limit alarm (adjustable alarm point) functions. M7 pointer local indication + mechanical upper and lower limit alarm (alarm point is adjustable), the upper limit alarm setting range is 50-100%, the lower limit alarm setting range is 0-50%, and the alarm hysteresis setting range is 0-5% , When the relay output is connected to the FB889 safety grid, an intrinsic safety explosion-proof system can be formed.

2. The metal tube variable area flowmeter is applicable for flow measurement of medium with small diameter and low flow velocity.

3. There are low requirements for front and rear straight pipe sections.

4. Two displays are optional: the pointer indicating the instantaneous flow, the LCD displaying the instantaneous flow and the cumulative total (LCD type).

5. The float flowmeter adopts all metal structure, is suitable for high temperature, high pressure and strong corrosive medium

6. The flowmeter can be used in inflammable and explosive dangerous occasion.

7. The variable area flowmeter comes with the functions of data backup and power failure protection (LCD type).

8. High quality flowmeter features reliable operation, less maintenance and long service life.

9. Wide range ratio 10:1 is available.

10. There are multi parameter calibration, keyboard setting alarm (with alarm type).

11. There are optional external power supply or self-contained 3.6V lithium battery power supply.

Technical Parameter

PEACO-LZZH series of metal tube rotameter is a common area of flow measuring instrument in the industrial automation process control, featuring small size, stable and reliable operation, suitable for measuring of liquid, gas for the measurement of various flow in various environments.

| Model | PEACO-LZZH-2 (The pointer indicating instantaneous flow.) |

| Measuring range | Liquid (20℃) 2.5-160000L/h, Gas (20°C, 0.101325MPa) 0.07-4000m3/h |

| Range ratio | Standard type 10:1 |

| Pressure rating | Standard type: DN15mm-DN50mm 4.0MPa, DN80mm-DN150mm, 1.6MPa |

| Pressure loss | 2kPa-20kPa |

| Medium viscosity | DN15mm: η<5mPa.s |

| DN25mm: η<250PFa.s | |

| DN50mm-DN150mm: η<300mPa.s | |

| Indicator for liquid crystal display | Instantaneous flow display numerical range:0-60000 |

| The cumulative flow display numerical range: 0-99999999x5 | |

| Indicator conversion accuracy | Instantaneous value: 0.5%FS±Lmsd |

| Cumulative value: 0.5%FS±Lmsd | |

| Liquid crystal temperature | -10℃-+85℃ |

| Influence of temperature | 0.5%/10℃ |

| Guard time | Data power-off protection period of 10 years |

| Power supply mode | Two-wire system, DC24V |

| Load resistance | 4~20mA 0~600Ω |

| Power consumption | 25 mW |

| Alarm mode | Solid state relay, current 200mA, voltage 50V, regardless of AC and DC power supply interface and the other part of the isolation. |

| Explosion proof mark: Intrinsically safe | iaIICTS |

| With the security grid model | FB906 |

| Cable interface | M201x.5 |

| Protection grade | IP65 |

| The implementation of product standards | JB/T6844-93 JJG257-2007 |

| Flange connection |

Flange connection standard HG20592-2010 |

| Threaded connection* |

According to the diameter or according to customer requirements. |

| Hygienic clamp connection | According to the diameter or according to customer requirements. |

Note: Please tell us caliber, measuring medium, medium density, operating temperature, operating pressure, flow range, installation form (vertical or horizontal) when you are ordering.

Flow Range

| Nominal Diameter | Flow range | Pressure loss | |||||

| Liquid | Gas | Kong Banxing | Cone tube | ||||

| Conventional type | Anticcorrosion type | Water | Air | Water | Air | ||

| DN15mm | 2.5-25L/h 4.0-40L/h 6.3-63L/h 10-100L/h 16-160L/h 25-250L/h 40-400L/h 63-630L/h |

/ 2.5-25L/h 4.0-40L/h 6.3-63L/h 10-100L/h 16-160L/h 25-250L/h 40-400L/h |

0.07-7Nm3/h 0.11-1.1Nm3/h 0.18-1.8Nm3/h 0.28-2.8Nm3/h 0.48-4.8Nm3/h 0.7-7.0Nm3/h 1.0-10.0Nm3/h 1.6-16.0Nm3/h |

5.5 5.5 5.5 5.6 5.6 5.8 6.0 7.3 |

7.1 7.2 7.3 7.5 8.0 9.8 10.0 14.0 |

2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 |

2.6 2.6 2.6 2.6 2.6 2.6 2.8 3.2 |

| DN20mm | 63-630L/h 80-800L/h 100-1000L/h |

40-400L/h 63-630L/h 80-800L/h |

1.6-16.0Nm3/h 2.4-24.0Nm3/h 3.6-36.0Nm3/h |

5.8 5.9 7.0 7.4 |

8.2 9.3 12.5 13.0 |

2.2 2.2 2.2 2.3 |

2.4 2.6 2.8 3.0 |

| DN25mm | 63-630L/h 100-1000L/h 160-1600L/h 250-2500L/h 400-4000L/h |

40-400L/h 63-630L/h 100-1000L/h 160-1600L/h 250-2500L/h |

1.6-16.0Nm3/h 3.0-30.0Nm3/h 4.5-45.0Nm3/h 7.0-70.0Nm3/h 11.0-110.0Nm3/h |

5.7 5.9 6.0 6.8 9.2 |

7.2 7.7 8.8 12.0 19.0 |

2.4 2.4 2.5 2.6 3.0 |

3.2 3.3 3.4 3.8 4.5 |

| DN32mm | 500-5000L/h 800-8000L/h 1000-10000L/h |

400-4000L/h 500-5000L/h 800-8000L/h |

14.0-140.0Nm3/h 23.0-230.0Nm3/h 35.0-350.0Nm3/h |

5.9 6.8 10.0 |

7.5 8.8 11.0 |

2.6 2.6 2.9 |

4.5 4.8 5.1 |

| DN40mm | 630-6300L/h 1000-10000L/h 1200-12000L/h |

400-4000L/h 630-6300L/h 1000-10000L/h |

18.0-180.0Nm3/h 25.0-250.0Nm3/h 40.0-400.0Nm3/h |

6.0 7.2 12.0 |

7.8 9.5 12.0 |

3.0 3.3 3.6 |

4.9 5.2 6.8 |

| DN50mm | 630-6300L/h 1000-10000L/h 1600-16000L/h |

400-4000L/h 630-6300L/h 1000-10000L/h |

18.0-180.0Nm3/h 25.0-250.0Nm3/h 40.0-400.0Nm3/h |

6.8 9.4 14.5 |

8.6 10.4 15.5 |

3.3 3.8 4.3 |

7.4 7.7 8.4 |

| DN65mm | 1600-16000L/h 2000-20000L/h 2500-25000L/h |

1000-10000L/h 1600-16000L/h 2000-20000L/h |

40.0-400.0Nm3/h 65.0-650.0Nm3/h 100.0-1000.0Nm3/h |

6.8 10.0 12.8 |

9.5 13.8 17.5 |

3.4 3.4 3.5 |

7.5 8.1 9.4 |

| DN80mm | 2500-25000L/h 4000-40000L/h |

1600-16000L/h 2500-25000L/h |

70.0-700.0Nm3/h 100.0-1000.0Nm3/h |

6.9 8.0 |

12.9 18.5 |

3.6 4.6 |

6.9 8.9 |

| DN100mm | 6300-63000L/h 10000-100000L/h |

4000-40000L/h 6300-630000L/h |

160.0-1600.0Nm3/h 250.0-2500.0Nm3/h |

8.5 8.8 |

19.2 19.6 |

5.8 6.4 |

12.0 12.8 |

| DN125mm | 12000-120000L/h | 10000-100000L/h | 300.0-3000.0Nm3/h | 9.0 | 20.3 | 7.0 | 13.5 |

| DN150mm | 16000-160000L/h | 12000-120000L/h | 400.0-4000.0Nm3/h | 9.2 | 20.8 | 7.1 | 13.8 |

| ZH | The pointer indicating instantaneous flow. | Display form | ||||||||||

| DH | The pointer indicating the instantaneous flow with signal output. | |||||||||||

| DN15mm-DN 150mm | Nominal diameter | |||||||||||

| Lower-upper (not standard) | Structure form | |||||||||||

| H1 | Left into, right out | |||||||||||

| H2 | Right into, left out | |||||||||||

| AA | Side into, side out | |||||||||||

| LA | Bottom side | |||||||||||

| N | Flange connection (not standard) | Connection mode | ||||||||||

| L | Thread connection | |||||||||||

| W | Hygienic clamp connection | |||||||||||

| RR4 | 304 1Cr18Ni9Ti | Measuring tube material | ||||||||||

| RR6 | 316L 00Cr17Ni14Mo2 | |||||||||||

| RR6L | 316 0Cr18Ni12Mo2Ti | |||||||||||

| HC4 | Hastelloy C alloy | |||||||||||

| Ti | Titanium alloy | |||||||||||

| F | 304 lining PTFE | |||||||||||

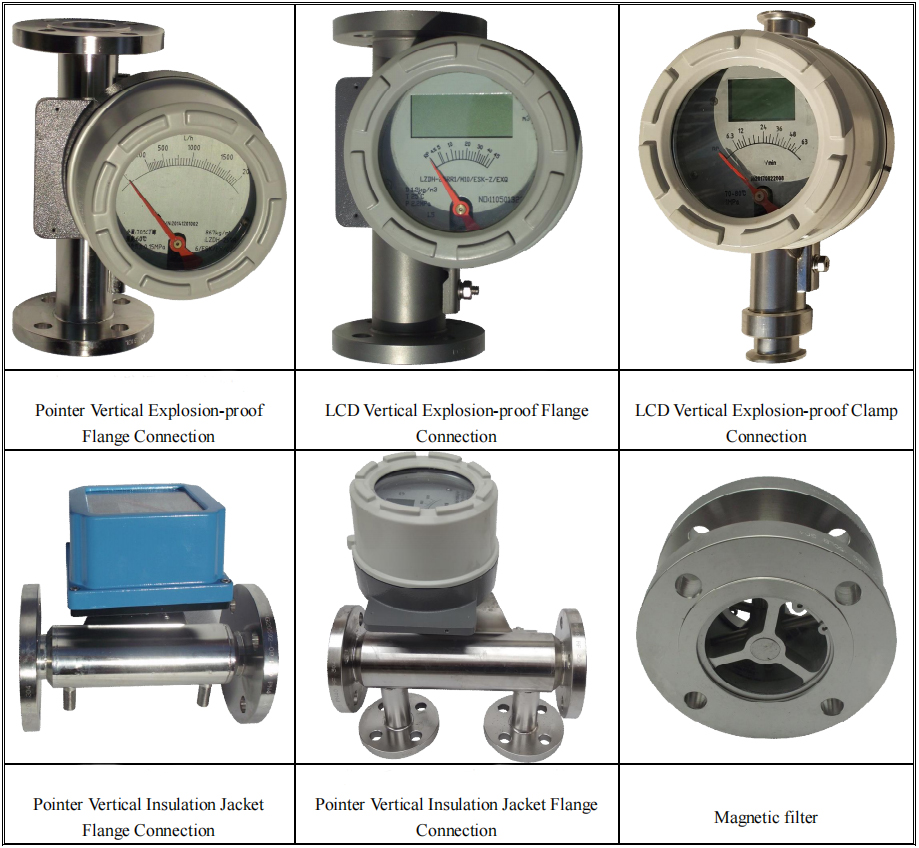

| M7 | Square indicator, the pointer indicates instantaneous flow. | Indicator type | ||||||||||

| M9 | Square indicator with liquid crystal display. | |||||||||||

| M10 | Circular (explosion) indicator, the pointer indicates instantaneous flow. | |||||||||||

| M12 | Circular (explosion) indicator with liquid crystal display. | |||||||||||

| N | No output (not standard) | |||||||||||

| ESK | 4-20mA current output | |||||||||||

| EX | 4-20mA current output, intrinsically safe explosion-proof type | |||||||||||

| H | With HART protocol | |||||||||||

| K1 | With upper limit alarm | |||||||||||

| K2 | With lower limit alarm | |||||||||||

| K12 | With alarm | |||||||||||

| D | DC24V two-wire system | |||||||||||

| L | 3.6V lithium battery | |||||||||||

| T | With insulation jacket. | Additional features | ||||||||||

| HT | The temperature is higher than 120℃. | |||||||||||

| Q | Gas | Measuring medium | ||||||||||

| Y | Liquid | |||||||||||

| DH | DN25MM | RR4 | M7 | ESK | D | Q | (example) | |||||

For more flowmeters to choose, please contact us.

KNOWLEDGE BASE --- Working Principle of Variable Area Flowmeter

The measured medium flows through the float of the measuring tube from bottom to top and the upper and lower ends generate differential pressure to form a lift force. When the lift force received by the float is greater than the weight of the float immersed in the fluid, the float will rise, and the area of the annular gap will increase accordingly. The fluid flow rate drops rapidly, the differential pressure at the upper and lower ends of the float decreases, and the lifting force acting on the float decreases with it. When the lifting force is balanced with the weight of the float immersed in the fluid, the float is stable at a certain position, corresponding to the size of the measured medium flow. The float has a built-in magnetic steel. When the float moves up and down with the medium, the magnetic field changes with the movement of the float.

As for the common type of variable area flowmeter, the follow-up magnet in the local indicator is coupled with the magnet in the float to rotate, and at the same time drive the pointer to indicate the flow rate at this time through the dial.

On the other hand, for the intelligent type, the follow-up magnet in the intelligent indicator is coupled with the magnet in the float, and rotates, and drives the sensor magnet and pointer at the same time, and converts the magnetic field change into an electrical signal through a magnetic sensor. After conversion, digital filtering, temperature compensation, microprocessor processing, D/A output, LCD liquid crystal display will show the instantaneous flow and cumulative flow.