- Stock: In Stock

- Model: PEACO-C2000VA

- SKU: PEACO-TT-2000VA

Available Options

Toroidal step down transformer features high power 2000VA, 230V input to 50-0-50V output, custom made toroidal transformers are also available. High polymer PET polyester film, high temperature resistance, good insulation performance, QZ-2 industrial grade copper wire, high mechanical strength, double insulating paint, low loss, high flux toroidal transformer core, widely used in medical equipment, automatic control equipment, home appliance speaker equipment, monitoring equipment, broadcasting system, solar wind energy, electronic communication, floor heating power supply, wall heating power supply, etc.

Features

- High temperature resistance up to 130℃. High polymer PET polyester film, good insulation performance.

- High silicon toroidal transformer core with full copper wire windings, smooth and flat with small gap, longer service life.

- Double insulated enameled wire winding, standardized winding process and welding level.

- QZ-2 industrial copper wire, double insulation, high mechanical strength, low operating noise, little interference, high stability.

- Energy-conserving, smaller no-load standby losses, higher energy conversion efficiency up to 96%.

- Normal working at -30℃. No high frequency electromagnetic radiation.

- Widely used in solar inverter industry, medical equipment industry, machinery and equipment industry, stepping motor industry, outdoor lighting industry, etc.

Specification

| Model | PEACO-C2000VA |

| Rated power | 2000VA (Max.) |

| Input voltage* | 110V, 120V, 220V, 230V, 240V |

| Output voltage* | 2x6V, 2X12V, 2X15V, 2X24V, 2X30V, 2X35V, 2X40V, 2X50V, 2X115V, 12V, 24V, 48V, 110V, 220V |

| Rated current | 4A (Max.) |

| Rated frequency | 50Hz/60Hz |

| No-load loss | ≤5W |

| Voltage strength | PRI-SEC: DC2500V |

| Insulation impedance | PRI-SEC: ≥500MΩ |

| Input lead | UL1015-16# RED RED |

| Output lead | UL1015-16# BLK BLK |

| Net weight | 14.9 kg |

| Product dimension | 200*58*85mm |

| Mounting plate | 180*180mm (Standard) |

| Hole distance | 190*190mm, 170*170mm double holes |

| Pore size | 5*10mm |

| Base Type* | Stoving varnish (Standard), galvanization (Optional) |

| Certification | CE, RoHS, CQC, UL |

- * denotes optional or customized parameters and you can select every parameter in drop-down lists to complete your order.

- Magnetic shield, electrostatic shield and central hole filled with epoxy resin can be customized for your needs if needed.

Toroidal Transformer Winding

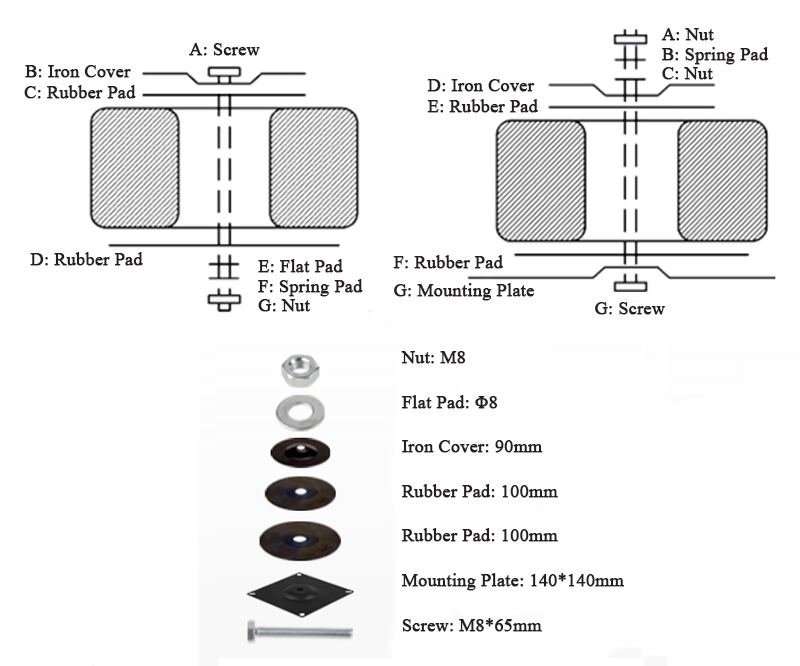

Toroidal Transformer Mounting & Accessories

Toroidal Transformer Packaging

Why does the power transformer of the amplifier get hot?

Reasons

1. Environment: The installation space may be too closed and not ventilated. The power transformer is not suitable to install in this environment.

2. Usage: The power transformer may be overloaded for a long time, but it can be used with overloaded for a short time.

3. Manufacturing material: The transformer may be made of inferior materials. For instance, isolation transformers iron cores are made of recycled waste, copper wires are not made of pure copper but aluminum, wires are too thin. Such problems may be the cause of the heat.

4. Design: Many parameters of the power transformer are relative to the temperature rise and the comprehensive matching of parameters is particularly important for the design of toroidal transformers.

Solutions

1. Disconnect the circuit, ventilate and dissipate heat. After its cooling, check whether there is obvious damage to components. For example, thereis flowing liquid, resistors get burnt and black, transistors and integrated circuits get burst, etc.

2. Buy a transformer with a higher power than your own needs and it is necessary not to use transformer with overload to increase the pressure of the transformer.

3. Purchase a qualified power transformer and install a temperature control protection device if necessary, which can disconnect the circuit in time and have a protection function.