- Stock: In Stock

- Model: PEACO-C3000VA

- SKU: PEACO-TT-3000VA

Available Options

Singls phase toroidal transformer comes with 3000VA rated power, optional primary and secondary voltages. High quality with CE, UL and RoHS compliant. Ideal toroidal step down transformer for power supply circuitry of electric machines and electronic devices with low nonload losses.

Features

- High temperature resistance up to 130℃. High polymer PET polyester film, good insulation performance.

- High silicon toroidal transformer core with full copper wire windings, smooth and flat with small gap, longer service life.

- Double insulated enameled wire winding, standardized winding process and welding level.

- QZ-2 industrial copper wire, double insulation, high mechanical strength, low operating noise, little interference, high stability.

- Energy-conserving, smaller no-load standby losses, higher energy conversion efficiency up to 96%.

- Normal working at -30℃. No high frequency electromagnetic radiation.

- Widely used in solar inverter industry, medical equipment industry, machinery and equipment industry, stepping motor industry, outdoor lighting industry, etc.

Specification

| Model | PEACO-C3000VA |

| Rated power | 3000VA (Max.) |

| Input voltage* | 110V, 120V, 220V, 230V, 240V |

| Output voltage* | 2x6V, 2X12V, 2X15V, 2X24V, 2X30V, 2X35V, 2X40V, 2X50V, 2X115V, 12V, 24V, 48V, 110V, 220V |

| Rated current | 125A (Max.) |

| Rated frequency | 50Hz/60Hz |

| No-load loss | <6.23W |

| Voltage strength | PRI-SEC: DC2500V |

| Insulation impedance | PRI-SEC: ≥500MΩ |

| Input lead | UL1672-18# RED RED |

| Output lead | UL1015-18# BLK BLK |

| Net weight | 22.0 kg |

| Product dimension | 230*65*90mm |

| Mounting plate | 220*220mm (Standard) |

| Hole distance | 210*210mm, 190*190mm double holes |

| Cooling | Natural air cooling |

| Base Type* | Stoving varnish (Standard), galvanization (Optional) |

| Certification | CE, RoHS, CQC, UL |

- * denotes optional or customized parameters and you can select every parameter in drop-down lists to complete your order.

- Magnetic shield, electrostatic shield and central hole filled with epoxy resin can be customized for your needs if needed.

Toroidal Transformer Winding

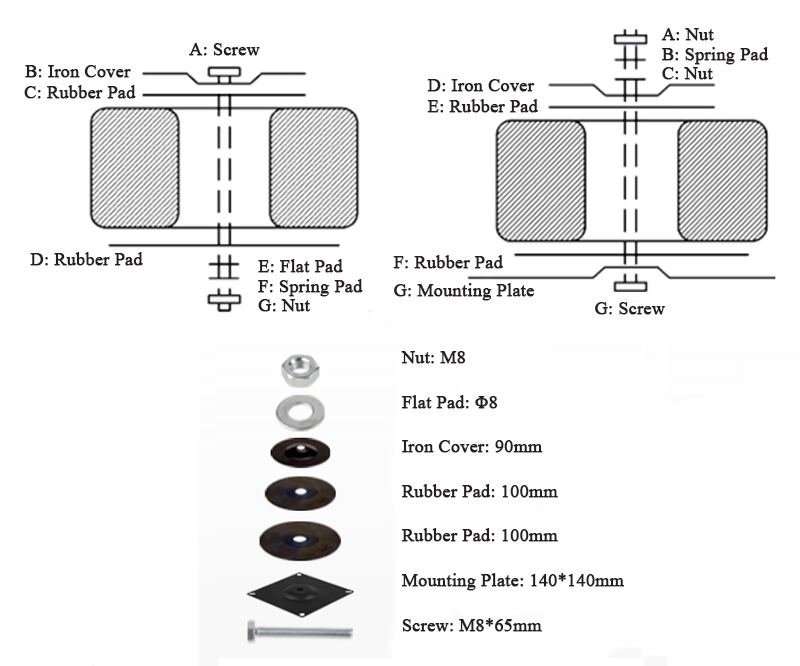

Toroidal Transformer Mounting & Accessories

Toroidal Transformer Packaging

The Relationship between Iron Core and Power of Toroidal Transformer

There is a direct relationship between the iron core and the power of the toroidal transformer. The iron core size of the toroidal transformer is proportional to the power. Namely, the greater the power is, the larger its volume will be. When the transformer power is larger, the magnetic circuit of the iron core is required to be longer, resulting in a larger volume of the iron core, which is mainly related to the iron core material.

The power of the toroidal transformer is determined by the material and cross-sectional area of the iron core. The cross-sectional area refers to the cross-sectional (rectangular) area of the core column wrapped by the winding. After measuring the cross-sectional area S of the iron core, the power P of the transformer can be estimated according to P=S2/1.5. The unit of S in the formula is cm2. For example, iron core cross-sectional area S=7cm2, power P=S2/1.5=7*7/1.5=33W. Without various errors, the actual nominal power is 30W.

Usually, the iron core is made of silicon steel sheets by seamless rolling. Wht the silicon steel sheets are used to make the iron core of the transformer? Because the silicon steel sheet itself is a magnetic substance with strong magnetic conductivity. The large magnetic induction intensity can be achieved to reach the condition of reducing the iron core, but this does not mean that the volume of the iron core can be infinitely reduced with high power. The reason is that the smaller the iron core is , the more difficult the production process will be. Due to the limitation of the production process, the iron core can not be as small as you want.

When the toroidal transformer works in the AC state, it will generate power loss, usually this power loss is called iron loss, which is also known as hysteresis loss and eddy current loss. Such losses are caused by the existence of hysteresis in the magnetization process of the iron core. The magnitude of this loss is proportional to the area enclosed by the hysteresis loop of the material. Then, we must reduce this power loss by increasing the core area when we need more power.

Therefore, if you want high power, the larger volume of the iron core is needed, so that the power can reach the required value after removing its iron loss. In fact, the power is also related to the number of turns of the wire winding and the diameter of the wire.