- Stock: In Stock

- Model: PEACO-DSP86

- SKU: PEACO-DSP86

Available Options

Specification

| Model | PEACO-DSP86 |

| Max. Input Power | 300W |

| Input Voltage Range | 48V-80V AC (<90V, >24V is recommended) |

| Output Peak Current Range | 2A-6A |

| Control Mode | Step and direction |

| Protection Functions | Over-voltage, under-voltage, over-current protections. |

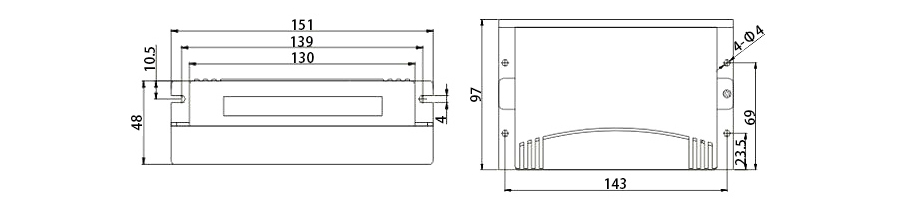

| Dimension | 151*97*48mm |

| Mounting Hole Distance | 143mm |

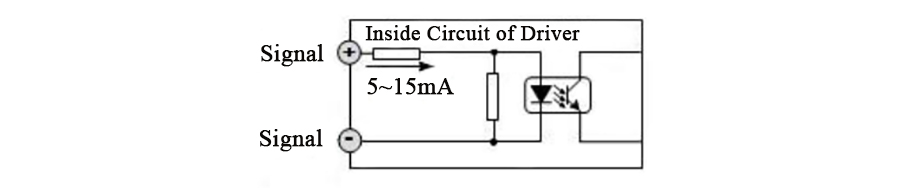

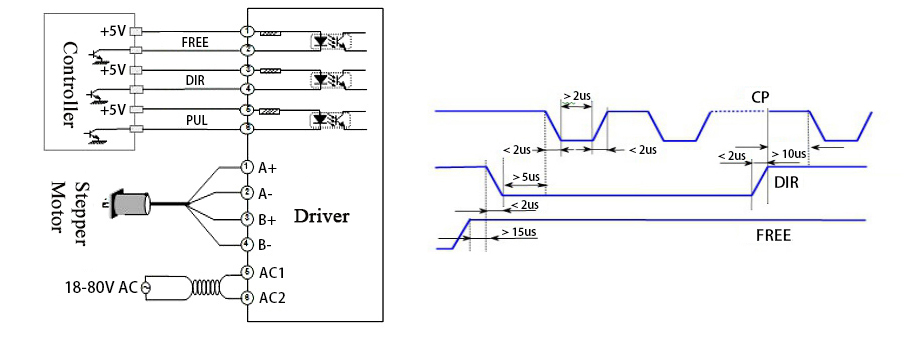

Pulse Signal

- PUL+ is the positive end of pulses input pin, PUL- is the negative end of pulse input pin.

- DIR+ is the positive end of direction input pin, DIR- is the negative end of direction input pin.

Enable Signal

- ENA+ is the positive end of direction input pin. This signal is used for enabling/disabling the stepper motor driver. High level for enabling the driver and low level for disabling the driver.

- ENA- is the negative end of direction input pin. Usually it is unconnected (enabled).

Motor Interface

- A+ and A- are connected to the positive and negative ends of the A-phase winding of the stepper motor.

- B+ and B- are connected to the positive and negative ends of the B-phase winding of the stepper motor.

- When the windings of A and B are switched, the direction of the motor can be reversed.

Power Interface

- AC power supply, recommended operating voltage range: 18V-80VAC, power supply: >300W, voltage: <90V AC and >24V AC.

Indicator Lights

- The stepper motor driver has red and green indicators.

- The green indicator is the power indicator. When the motor driver is powered on, the green indicator is on.

- The red indicator is the fault indicator. When overvoltage or overcurrent faults occur, the fault indicator is on.

- After the fault is eliminated, the red light is off. When stepper driver is faulty, you need to power on and enable the stepper driver again to get rid of the fault.

Installation Instructions

- The external dimension of the stepper motor driver is 151*97*48mm and the installation hole distance is 143mm.

- Both horizontal and vertical installation are available, but vertical installation is recommended. When installing, it should be close to the metal cabinet for heat dissipation.

Switch Options

| Output Peak Current | Output REF Current | SW1 | SW2 | SW3 |

| 2.00A | 2.40A | on | on | on |

| 2.57A | 3.08A | off | on | on |

| 3.14A | 3.77A | on | off | on |

| 3.71A | 4.45A | off | off | on |

| 4.28A | 5.14A | on | on | off |

| 4.86A | 5.83A | off | on | off |

| 5.43A | 6.52A | on | off | off |

| 6.00A | 7.20A | off | off | off |

Micro Step Selection

| PUL/REV | SW5 | SW6 | SW7 | SW8 |

| 400 | on | on | on | on |

| 800 | off | on | on | on |

| 1600 | on | off | on | on |

| 3200 | off | off | on | on |

| 6400 | on | on | off | on |

| 12800 | off | on | off | on |

| 25600 | on | off | off | on |

| 51200 | off | off | off | on |

| 1000 | on | on | on | off |

| 2000 | off | on | on | off |

| 4000 | on | off | on | off |

| 5000 | off | off | on | off |

| 8000 | on | on | off | off |

| 10000 | off | on | off | off |

| 20000 | on | off | off | off |

| 40000 | off | off | off | off |

Notice: When the command input is not compatible with TTL, a series resistor for current limiting should be added at each signal input port according to the voltage level you use. Such as, 24V with 2KΩ.

Stepper Motor Driver Installation Dimension (Unit:mm)

KNOWLEDGE BASE --- Advantages of Stepper Motor Driver

Low-frequency oscillation exists in stepper motors, especially in reactive motors. However, stepper motor driver can completely eliminate it. If your stepper motor sometimes needs to work in the resonance zone, such as arcing, it is a good option to use a stepper motor driver to improve the output torque of the motor.

For example, a stepper driver can increase 30%-40% of torque of a three-phase reactive motor and can also improve the motor resolution, because the step angle is reduced and the step uniformity is improved.

Generally speaking, the performance of stepper motor control system not only depends on the performance of stepper motor itself, but also depends on that of stepper motor driver.