Electromagnetic Clutch, 6Nm-400Nm, 1800 rpm

- Stock: In Stock

- Model: PEACO-FCD-1

- SKU: PEACO-FCD-1

$234.68

Ex Tax: $234.68

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

High-quality electromagnetic clutch from the factory, dry single-plate type, 1800rpm max. working speed, 6Nm, 25Nm, 200Nm, 400Nm static torque, DC 24V voltage, responses fast and brakes stably. Great shaft-mounted electromagnetic clutch for transmitting torque mechanically.

For the electromagnetic clutch and brake catalogue and user manual, please visit here Peaco Support Electromagnetic Clutch and Brake Catalogue.

Specification

| Model | FCD-1-006 | FCD-1-015 | FCD-1-025 | FCD-1-050 | FCD-1-100 | FCD-1-200 | FCD-1-400 | ||

| Static Friction Torque [kgm](Nm) | 0.6 (6) | 1.5 (15) | 2.5 (25) | 5.0 (50) | 10 (100) | 20 (200) | 40 (400) | ||

| Dynamic Friction Torque [kgm](Nm) | 0.5 (5) | 1.0 (10) | 2.0 (20) | 4.0 (40) | 8 (80) | 16 (160) | 32 (320) | ||

| Power [DC 24V](W) at 20℃ | 11 | 15 | 20 | 25 | 35 | 45 | 60 | ||

| Weight (kg) | 0.66 | 1.19 | 2.11 | 3.8 | 6.9 | 13 | 23.6 | ||

| Rated Voltage | DC 24V | ||||||||

| Max. Speed (r/min) | 1800 | ||||||||

| Certification, Warranty | CE, 12 months | ||||||||

Features

- Suitable for connection, speed change, cutting, inching, forward and reverse rotation, buffer starting, high-frequency operation, power switching, overload protection, etc.

- Equipped with non-asbestos lining, the clutch has good wear resistance and a longer service life.

- Super thin design allows less occupied space, with a flywheel at the input side and transmission shaft at the output side, simple and easy to install.

- Used in various Sorting and Packaging applications including food processing equipment, packaging machinery, conveyor drives, printing and copy machines, automated manufacturing, and assembly.

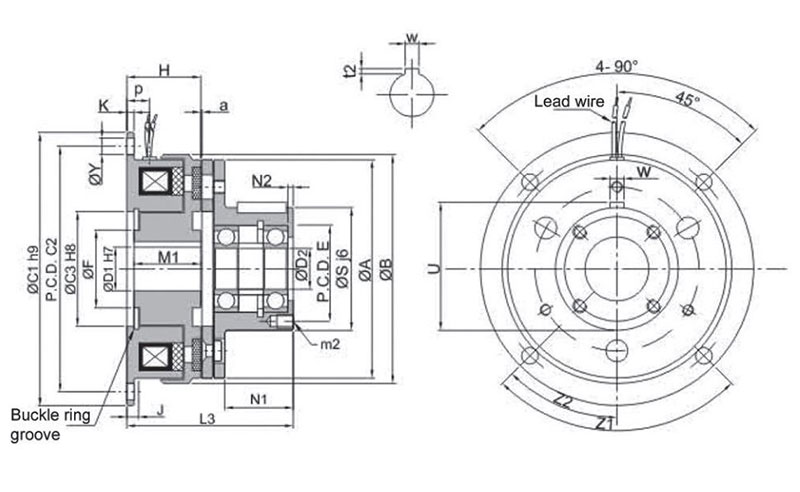

Electromagnetic Clutch Dimension (Unit: mm)

| Model | FCD-1-006 | FCD-1-015 | FCD-1-025 | FCD-1-050 | FCD-1-100 | FCD-1-200 | FCD-1-400 | ||||||||

| Radial Direction | A | 63 | 80 | 100 | 125 | 160 | 200 | 250 | |||||||

| B | 67.5 | 85 | 106 | 133 | 169 | 212.5 | 264 | ||||||||

| C1 | 80 | 100 | 125 | 150 | 190 | 230 | 290 | ||||||||

| C2 | 72 | 90 | 112 | 137 | 175 | 215 | 270 | ||||||||

| C3 | 35 | 42 | 52 | 62 | 80 | 100 | 125 | ||||||||

| D1 | 12 | 15 | 15 | 20 | 20 | 25 | 25 | 30 | 30 | 40 | 40 | 50 | 50 | 60 | |

| D2 | 12 | 15 | 20 | 25 | 30 | 40 | 50 | ||||||||

| E1 | 26 | 31 | 41 | 49 | 65 | 83 | 105 | ||||||||

| E2 | 33 | 37 | 47 | 52 | 62 | 74.5 | 101.5 | ||||||||

| F | 23 | 28.5 | 40 | 45 | 62 | 77 | 100 | ||||||||

| S | 38 | 45 | 55 | 64 | 75 | 90 | 115 | ||||||||

| U | 39.5 | 47 | 57 | 67 | 78 | 93.5 | 118.5 | ||||||||

| Y | 5 | 6 | 7 | 7 | 9.5 | 9.5 | 11.5 | ||||||||

| Axis Direction | H | 24 | 26.5 | 30 | 33.5 | 37.5 | 44 | 51 | |||||||

| J | 3.5 | 4.3 | 5 | 5.5 | 6 | 7 | 8 | ||||||||

| K | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | ||||||||

| L1 | 43 | 51 | 61 | 70.5 | 84.5 | 100.5 | 118 | ||||||||

| L2 | 31.5 | 35 | 41 | 46.5 | 53.5 | 64.5 | 75 | ||||||||

| L3 | 51.5 | 60 | 71 | 86.5 | 103.5 | 124.5 | 145 | ||||||||

| M1 | 22 | 24 | 27 | 30 | 34 | 40 | 47 | ||||||||

| M2 | 15 | 20 | 25 | 30 | 38 | 45 | 54 | ||||||||

| N1 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | ||||||||

| N2 | 2 | 2 | 3 | 2 | 3 | 5 | 6 | ||||||||

| P | 7.5 | 8 | 9 | 9 | 11.5 | 13 | 15.5 | ||||||||

| T | 6 | 8 | 10 | 12 | 15 | 18 | 22 | ||||||||

| W | 4 | 5 | 5 | 7 | 7 | 10 | 12 | ||||||||

| Z1 | 4°~90° | ||||||||||||||

| Z2 | 60° | 45° | 30° | 45° | 25° | ||||||||||

| m1 | 2-M4 | 2-M5 |

2-M5 | 2-M6 | 2-M8 | 2-M8 |

2-M10 | ||||||||

| m2 | 3-M4*0.7P*4L | 3-M4*0.7P*6L |

4-M4*0.7P*8L | 4-M4*0.7P*8L | 6-M5*0.8P*8L | 4-M6*1P*12L |

4-M6*1P*12L | ||||||||

| a | 0.2 (±0.05) | 0.3 (+0.05-0.1) | 0.5 (-0-0.2) | ||||||||||||

| b | 4 | 5 | 5 | 7 | 7 | 10 | 12 | ||||||||

| t1 | 1.8 | 2.3 | 2.3 | 2.3 | 2.3 | 3.3 | 3.3 | 3.3 | 3.3 | 3.8 | 3.8 | 3.8 | 3.8 | 5 | |

| t2 | 1.8 | 2.3 | 2.3 | 3.3 | 3.3 | 3.8 | 3.8 | ||||||||

Note: Please write the diameter D1 for each model you need in the Comments Box while checking out.

Electromagnetic Clutch Dimension

FCD-1 Bearing Guide Seat Type

Electromagnetic Clutch Installation

The flange is installed on the machine wall, and the bearing guide seat is connected to the sprocket.