When power is transmitted over long and short distances, there are inherent losses in the system. The magnitude of these losses is greater when the current is higher than (at low voltages) low currents. Power transmission lines are often made of copper to minimize transmission-related losses. Copper provides the lowest resistance of all conductive materials. Therefore, long-distance transmission requires electricity with both high voltage and low current. However, high voltage is not safe for consumers and is not suitable for most appliances. The rated voltage of consumer appliances is usually 110V or 220V.

Generally speaking, on the one hand, a step-up transformer is located at the power plant and steps up the voltage flowing from the power plant to the long-distance distribution grid. On the other hand, a step-down transformer reduces the voltage of the power flow received at the local distribution level. Firstly, long-distance traffic is reduced to a level acceptable to the local distribution, then long-distance traffic will arrive at the residence and office.

Step-down transformers have an important impact on our daily lives and basic industrial production. The power produced by the power station is high voltage. There is a fact that there would be no electricity in the home without a step-down transformer. Therefore, step-down transformers are necessary when we need to transmit electricity from a power station to a residential house or office.

So what is a step-down transformer? What is the structure of a step-down transformer? What is the working principle of a step-down transformer?

Usually, transformers are classified into step-up transformers and step-down transformers. A step-up transformer increases the voltage of the input current, while a step-down transformer reduces the voltage of the input current. The input voltage is called the primary voltage and the output one is called the secondary voltage. In other words, a step-down transformer steps down the voltage applied on the primary winding and provides the reduced voltage on the secondary side. However, the power and frequency remain the same during the process.

How a Step-down Transformer Works?

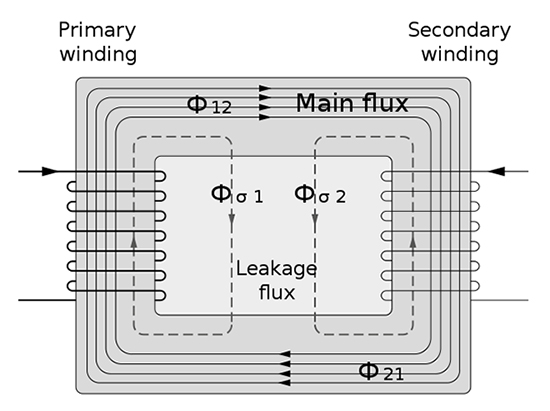

The working principle of the transformer is Faraday's law of electromagnetic induction. Namely, when the magnetic flux connecting the circuit changes, the electromotive force induced in the circuit is proportional to the rate of change of the magnetic flux. Transmission in transformers is achieved through the mutual induction between windings. The number of turns of the primary winding and the secondary winding respectively determines the electromotive force induced between the two windings and this ratio is called the turns ratio. However, what determines the step-down capability of a step-down transformer? It depends on the turn ratio of the primary and secondary coils. The transformer's secondary coil still has less magnetic flux compared to the primary coil because the number of windings in the secondary coil is also smaller than that in the primary coil. Therefore, the electromotive force induced in the secondary coil will be smaller, which will eventually reduce the voltage in the secondary winding but not the primary winding.

Here is the formula for designing a step-down transformer.

Ns/Np=Vs/Vp

Ns=Secondary winding turns

Np=Primary winding turns

Vs=Secondary winding voltage

Vp=Primary winding voltage

To make the transformer work as a step-down transformer, the number of turns of the secondary winding must always be less than that of the primary winding of the transformer, i.e. Np > Ns.

For example, there is a step-down transformer whose secondary winding turns [Ns] is 400, primary winding turns [Np] is 8000 and input voltage [Vp] is 240V. Then, the voltage [Vs] on the secondary side can be calculated using the following formula:

Vs=Ns*Vp/Np

Then Vs=400*240/8000 and Vs=12V

Therefore, the voltage of the transformer's secondary winding is 12V and it is less than that of the primary winding.

Step-down Transformer Advantages

Step-down transformers are useful for reducing voltage. It is easier and cheaper to transfer power. Such DC step-down transformers offer over 99% efficiency, provide different voltage requirements, and are highly reliable and durable.

Step-down Transformer Application

Transformers are widely used in metal processing equipment, elevators, production lines, medical equipment, construction equipment, etc.

Power Supply System: Step-down transformers are used in power distribution systems. They are used to reduce the voltage when necessary during all phases of the power supply.

Electronic Equipment: Step-down transformers are used in various electronic equipment that operate at a lower voltage than the supplied voltage.

For example, a power plant generates 20kV of electricity, which is then boosted to 440kV for distribution over long distances. When the local substation receives, the voltage is reduced to 11kV by using a step-down transformer. Then, another step-down transformer reduces the voltage to 220V or 110V which is suitable for consumer use for distribution to individual consumers.

Peaco Support provides a wide selection of step-down transformers, including single-phase step-down transformers and three-phase step-down transformers. There are isolation transformers, control transformers, and autotransformers, whose voltage ranges from 480V to 12V. For example, 220V to 110V step-down transformer, 230V to 12V step-down transformer, 240V to 120V step-down transformer, 480V to 240V step-down transformer, 240V to 100V step down transformer, 440V to 220V step-down transformer, etc.