A variable frequency drive (VFD) is a motor controller that can control the speed of the motor by varying the frequency. Such devices do the smooth ramp up and ramp down during the start and stop of the induction motor. Many people look for VFDs that can club the phase conversion as well as the speed control in one device.

Why there is a need for a phase converter VFD?

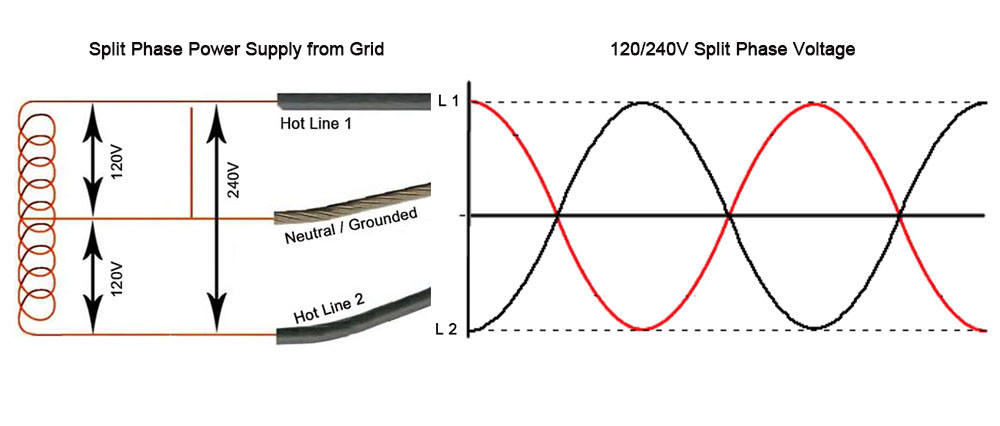

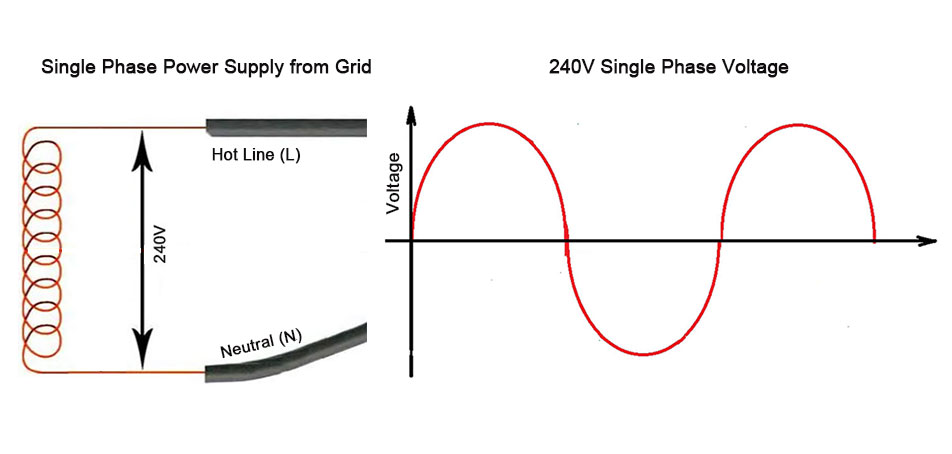

It is common to have a single-phase AC supply in many non-industrial zones like residential, agriculture, small industrialized, micro-industry, etc. Some countries, for example, the USA and Canada, have split phase voltage (single phase) with 2-hotlines L1 and L2. Each line carries 120V voltage with a phase difference of 180° from each other.

While many other countries like the EU, UK, China, India, Australia and New Zealand get the supply of single-phase with a single hotline L (220-240V) and one natural line N.

Hence, it is not an easy, convenient and economical solution to install a three-phase power grid or buy an expensive phase converter to operate a few motors.

Single phase to three phases VFD

Many people jump into a problem with how to power up a 3-phase induction motor with a single-phase power supply in the simplest way. So, the best countermeasure to encounter such a problem is to use a single phase to three phase VFD. These VFDs are rated and sized based on the three-phase current rating available on your motor nameplate.

Let us look over some case studies to choose the correct single-phase to three-phase VFD to drive a 3-phase induction motor.

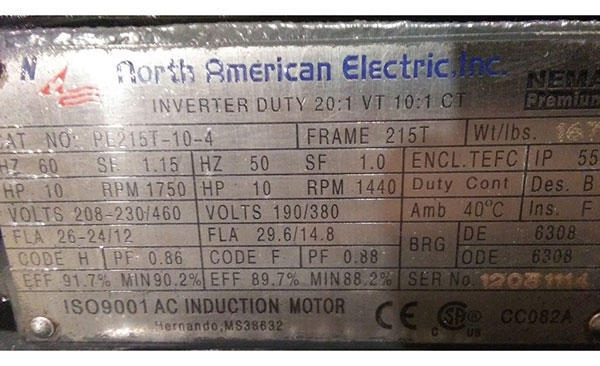

Case study 1: If you want to run a 10hp three phase motor having a 9-leads wire connection at 230V or 460V voltage and 60Hz frequency. Then such a 10hp motor will drain 24A current when operated at three-phase 230V and 12A with 460V voltage supply as mentioned in the following motor nameplate.

Now, the users can have the option to operate the motor at either 230V three-phase or 460V three-phase voltage. But the VFD has a drawback to reaching such a high 460V voltage when your input supply is a single phase/split phase 240V. Therefore, we recommend setting the motor wire connection with low voltage 230V and choosing the VFD that can deliver three-phase voltage 230V and full load current (FLA) 24~26 Amps from single phase supply.

Product: 10 hp (7.5 kW) VFD single Phase to three Phase

- Input voltage (single phase): 230~240V AC

- Output voltage (three phase): 230V

Case study 2: Following 3hp induction motor can be driven with a voltage of 400/440V. It will drain current 4.9/3.7A. So, Peaco Support single-phase to three-phase VFD that can deliver the rated current above the mentioned FLA is suitable to overcome the phase conversion problem.

Product: 5 hp (3.7 kW) VFD single Phase to three Phase or 3 hp (2.2 kW) VFD single Phase to three Phase

- Input voltage (single phase): 220~230V AC

- Output voltage (three phase): 440V

Do you need to oversize the variable frequency drive (VFD)?

Using standard 3-phase VFD for phase conversion of high-capacity motor (>5hp) can trigger the failure of VFD input diodes. It probably happens by connecting the same amperage on two-phase (split voltage) or 1-phase instead of three at the input terminal of VFDs. Generally, to encounter such an issue, you need to oversize the VFD to account for a larger output current.

Our specially designed single-phase to three-phase VFDs consider the above factor. Only the customer needs to finalize the suitable VFD for their applications based on the motor capacity, voltage, and rated output current.

For motor details, visitors can approach our sales executive via email.

Related Post:

- What is a VFD Drive and How a Variable Frequency Drive Works?

- What is Soft Starter? - Soft Starter Working, Diagram and Applications

- Variable Frequency Drive (VFD) FAQ

- How to Check AC Contactor?

- Difference between Auxiliary and Main Contacts

- Capacitor Switching Contactor: Function, Structure

- What is Contactor?