160W DC Brushless Vibration Motor, 24V/36V, Speed Control, 4000rpm

- Stock: In Stock

- Model: PEACO-PUTA160DCB

- SKU: PEACO-PUTA160DCB

$602.58

Ex Tax: $602.58

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

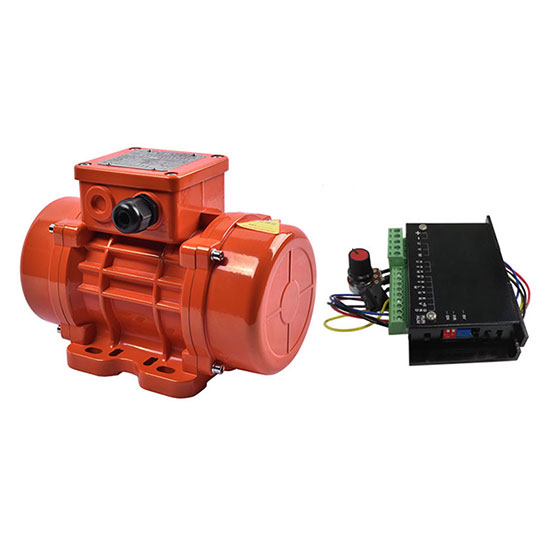

160W DC brushless vibration motor works with variable speed display controller at 4000rpm working speed and 24 volt or 36 volt voltage can be choosen for your vibration solutions. Reliable vibration motor is supplied from direct manufacturer with low vibration motor price, 1 year warranty. High performance vibration motor speed control for food machinery, screening machine, etc.

For vibration motors user manual, please visit here Peaco Support Vibration Motors User Manual.

DC Brushless vibrating motor specification

- Model: PEACO-PUTA160DCB/24-12, PUTA160DCB/36-12 (Optional)

- Name: DC Brushless Vibration Motor

- Power: 160W

- Vibration Frequency: 4000rpm

- Rated Voltage: 24V / 36V DC (Optional)

- Rated Current: 7.1 A / 6.3 A (for 24V / 36V DC)

- Excitation Force: 2.5 KN / 2.6 KN

- Frame No.: 12/8

- Shell Material: Aluminium alloy / stainless steel (Optional)

- Insulation Grade: F (The highest heat resistant temperature is 155℃)

- Protection Rank: IP65 (dustproof & waterproof)

- Cooling Mode: Natural cooling (IC410)

- Working System: S1 (Continuous Duty)

- Certificate: CCC, CE

- Warranty: 1 year.

- Weight : 5.5kg

- Package: Brushless vibration motor*1 + cable*1 + speed controller*1

Notes: The digital speed controller has been obsolete for the high power motor recently, you may choose the advanced black one.

DC Brushless Vibrating Motor Features

- DC brushless vibration motor is equipped with intelligent digital display controller, convenient and easy to adjust speed.

- The aluminum alloy & stainless steel vibration motor features pure copper enameled wire, all copper windings, and the stator is dipped in vacuum, F-class insulation level, high-temperature-resistant and 10 times longer life than ordinary motors.

- Brushless DC technology is adopted for high efficiency and energy saving and the power saving rate is up to 40%-60%.

- Outer shell is made of aluminium alloy / stainless steel with precision casting and a fully enclosed structure, small size, light weight, dust-proof, moisture-proof, not easy to rust, fast heat dissipation and low temperature rise.

- The electric vibrating motor is equipped with anti-vibration special protective sleeve for power line outlet to prevent the cable from the damage of long time vibration.

- Industrial vibration motor comes with pure copper wire and precision bearings, low noise, high wear resistance.

- The vibration motor is widely used with vibratory feeder, vibration machine, vibrating table, vibrating hopper feeder, concrete vibrating equipment and other industrial equipment.

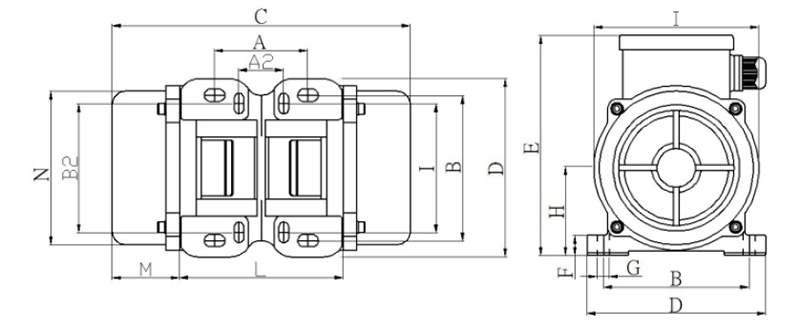

Vibration Motor Dimension (unit: mm)

| Frame No. | A | A2 | B | B2 | C | D | E | F | G | H | I | L | M | N | lead connection |

| 12 | 62-74 | 33 | 106 | 83-102 | 211 | 130 | 136 | 12 | 10 | 55 | 94 | 104 | 45 | 90 | M1.6*1.5 |

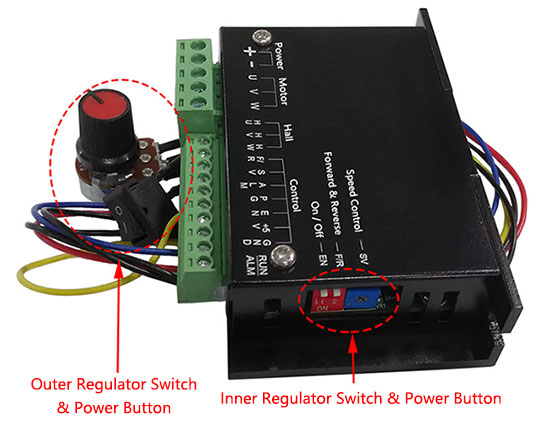

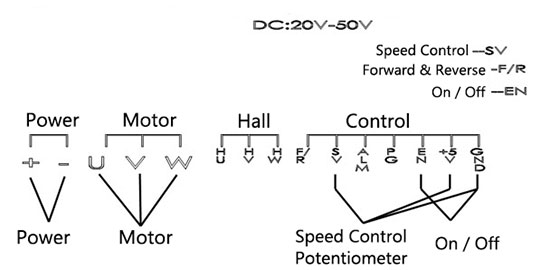

Vibration Motor Controller

Vibration Motor Controller Wiring

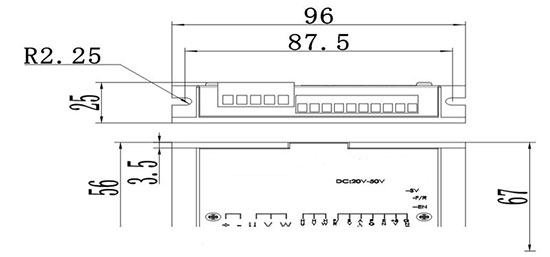

Vibration Motor Controller Dimension (unit: mm)

DC Brushless Vibrating Motor Applications

KNOWLEDGE BASE - What should I do if the vibration motor leaks?

When vibration motors have been used for many years, there will be some problems, which are very common. When dealing with this vibration motor leakage problem, users need to take different measures according to different reasons.

1. There may be a problem with the ground wire connection.

For some new users, when operating the vibrating motor for the first time, there may be a wrong ground wire connection. This kind of problem can be found by checking the cable to find the root of the problem and then find out and correct it.

2. Cable aging affects insulation.

Some vibration motors may be used for too long time and there is a problem of cable aging in some places, especially in harsh environments, the aging will be accelerated. Therefore, the electric vibration motors with a relatively long service life have leakage. First of all, it is necessary to check whether the skin of the lead wire is aging. If it is so, what users need to do is to just replace it in time, then it can still be used normally.

Additionally, there are also some common reasons, for example, the winding is damp, damaged or it may be that too much dirt has accumulated on the wiring board inside and it is also prone to leakage. In response to such problems, drying treatment can be used to alleviate the dampness. And it is very important to replace the damaged areas and clean the accumulated dirt on the wire board timely.