10 hp 3 Phase AC Gear Motor, Gear Ratio 5~60

- Stock: In Stock

- Model: PGH-50-7500W

- SKU: XACGM-TP7500

$2,776.95

Ex Tax: $2,776.95

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

10 hp 3 phase AC gear motor provides optional rated voltage 220V/380V/460V/480V, 5~60 gear ratio, features high stability and precision, strong bearing capacity, and long lifespan. Reliable three-phase asynchronous motor for modern industrial production of all kinds of machinery and equipment to ensure smooth operation.

Navigation: Motors > Gear Motor > AC Gear Motor >10 hp 3 Phase AC Gear Motor, Gear Ratio 5~60

Specification| Model | PGH-50-7500W | ||

| Product Name | Medium Gear Motor | ||

| Product Type | Three-phase asynchronous motor | ||

| Rated Power | 7500W (10 hp) | ||

| Rated Voltage* | Three phase 220V/380V or other customized voltage 3-phase 400V, 440V, 460V, 480V | ||

| Rated Frequency | 50/60Hz | ||

| Rated Speed | 1420/1720rpm | ||

| Gear Ratio* | 5:1/ 10:1/ 15:1/ 20:1/ 25:1/ 30:1/ 40:1/ 45:1/ 50:1/ 60:1/ 70:1/ 80:1/ 90:1/ 100:1 | ||

| Protection Grade | IP54 | ||

| Material | Aluminum shell | ||

| Warranty | 1 year | ||

| Certification | CE | ||

| Installation* | Horizontal | ||

| Application | Automation equipment: mechanical equipment, packaging machine, die-cutting machine, assembly line equipment, etc. | ||

10 hp AC Gear Motor Output Torque

| Gear Ratio | 5 | 10 | 15 | 20 | 25 | 30 | 40 | 45 | 50 | 60 | |

| Output Speed (rpm) | 50Hz | 300 | 150 | 100 | 75 | 60 | 50 | 37 | 33 | 30 | 25 |

| 60Hz | 360 | 180 | 120 | 90 | 72 | 60 | 45 | 40 | 36 | 30 | |

| Output Torque (kg.m) | 50Hz | 22.4 | 44.8 | 67.3 | 89.7 | 122.2 | 134.6 | 179.5 | 202 | 244.4 | 269.3 |

| 60Hz | 18.2 | 36.4 | 54.6 | 72.8 | 91 | 109.2 | 145.6 | 163.8 | 182 | 218.5 | |

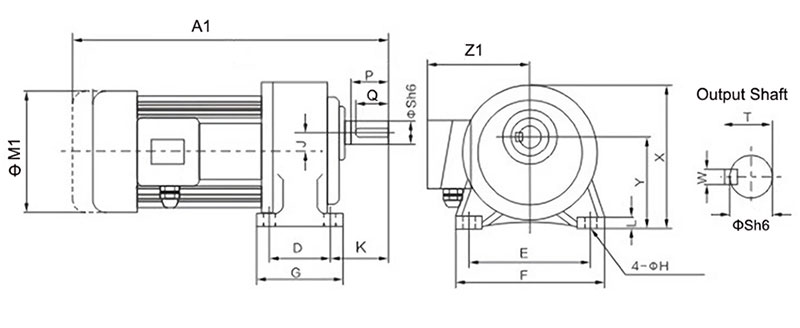

| Gear Ratio | Shaft Dia | A1 | A3 | D | E | F | G | H | L | J | K | M1 | X | Y | Z1 | Weight |

| 5~10 | Φ50 | 619 | 659 | 170 | 265 | 330 | 220 | 19 | 30 | 51.7 | 104 | 250 | 315 | 200 | 178 | 99 |

| 11~30 | Φ60 | 629 | 669 | 170 | 265 | 330 | 220 | 19 | 30 | 51.7 | 115 | 250 | 315 | 200 | 178 | 103 |

| 31~60 | Φ60 | 629 | 669 | 170 | 265 | 330 | 220 | 19 | 30 | 51.7 | 115 | 250 | 315 | 200 | 178 | 110 |

Notes:

1. A3 is the size of three-phase motors with brakes.

2. * denotes optional parameters and you can select every parameter in drop-down lists to complete your order.

Output Shaft Dimension

| Output Shaft | keyway | Key | |||

| Shaft Dia | P | W | T | Q | SPEC |

| Φ45 | 75 | 12 | 48.5 | 70 | 12*8*70 |

| Φ50 | 80 | 14 | 54 | 75 | 14*9*75 |

| Φ60 | 90 | 15 | 63.5 | 85 | 15*10*85 |

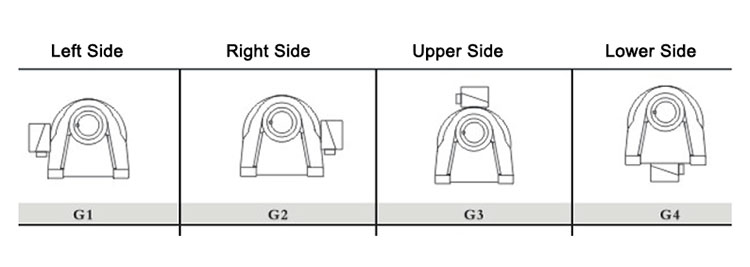

AC Gear Motor Terminal Box Direction (From Output Shaft)

KNOWLEDGE BASE

How to judge whether the gearbox is overloaded?

We can judge whether the gearbox is in overload state by observing and detecting the following aspects.

1. Check the rated power and actual output power of the motor.

The rated power of the motor is the maximum power that the motor can output at the rated speed. If the actual output power of the motor exceeds the rated power, then there may be an overload problem.

2. Observe the motor speed.

Motor speed refers to the number of revolutions per minute of the motor. If the actual speed of the motor is lower than the rated speed, the output power of the motor may be limited, which may also indicate the presence of an overload situation.

3. Check the transmission ratio of the gearbox.

The transmission ratio of the gearbox is the ratio of the speed of the output shaft to the speed of the input shaft. If the transmission ratio of the gearbox is too large, the power output of the motor may be limited, which is prone to overload problems.

4. Monitor the temperature of motor and gearbox.

In the case of overload, both the motor and the gearbox will produce large heat, resulting in an increase in temperature. Therefore, by monitoring the temperature of these devices, it is possible to preliminarily determine whether there is an overload situation.

5. Monitor the noise of the gearbox.

When the gearbox is overloaded, it may produce large noise due to the large load. Therefore, monitoring the noise of the gearbox is also a way to judge whether it is overloaded.

To sum up, judging whether the gearbox is overloaded requires comprehensive consideration of multiple factors and combined with actual observation and detection. If the gearbox is found to be overloaded, measures should be taken to adjust and maintain it in time to avoid further damage to the equipment.