Rotary Torque Sensor, Shaft to Shaft, 5 Nm-10000 Nm

- Stock: In Stock

- Model: PEACO-ZJ-A

- SKU: PEACO-ZJ-A

$1,099.19

Ex Tax: $1,099.19

Available Options

Free Shipping Worldwide.

By DHL/ FedEx/ UPS.

Lead Time 7-12 Days.

Mail Us for Lead Time of Custom Products.

MOQ 1.

Buy More Save More.

Shaft to shaft rotary torque sensor comes with a wide selection of capacity 5 Nm - 1000Nm, dynamic measurement of torque and speed, outputs both forward and reverse torque signals. High precision < ±0.2% F.S and stable and reliable performance. With transmitter for output signal DC 4-20mA, 0-5V, 0-10V, RS485.

Features and Benefits- The rotary torque sensor features dynamic measurement of torque and speed, non-contact transmission of power supply and signals and digitization of output signals.

- High testing precision, good stability and strong anti-interference for the shaft to shaft rotary torque sensor are available.

- The forward and reverse torque can be continuously measured without repeating zero setting.

- Rotary torque transducer can measure both static torque and dynamic torque.

- Reliable torque transducer can be used independently from the secondary instrument, and the output signal can be used directly by PLC and PC.

- The shaft to shaft rotary torque sensor can be customized according to customer requirements.

- Model: PEACO-ZJ-A

- Capacity: 5 Nm-10000 Nm. 5 Nm, 10 Nm, 20 Nm, 30 Nm, 50 Nm, 100 Nm, 200 Nm, 500 Nm, 1000 Nm, 2000Nm, 5000Nm, 10000Nm (Optional)

- Torque indication error: < ±0.2% F.S

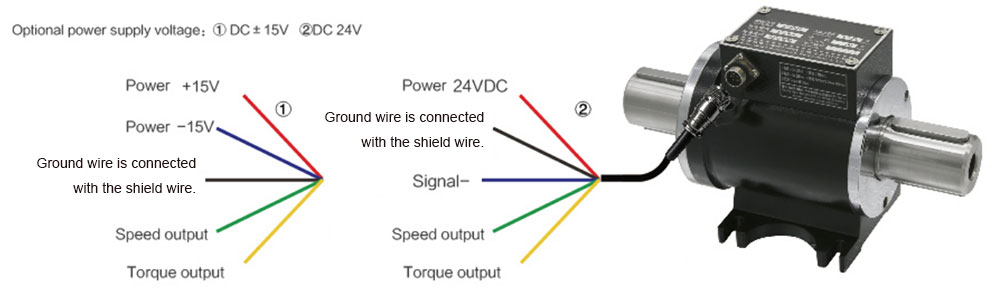

- Power supply voltage: DC 15V±5%, DC 24V (optional)

- Sensitivity: 1±0.2 mv/V

- Speed output signal: 60-2000 pulse /turn (optional)

- Nonlinear: ≤ ±0.2% F.S

- Zero torque frequency output: 10KHz

- Repeatability: ≤ ±0.2% F.S

- Positive torque full scale frequency output: 15KHz

- Lag: ≤ 0.2 F.S

- Reverse torque full scale frequency output: 5KHz

- Zero drift (24 hours) : ≤ 0.1% F.S

- Signal duty ratio: (50±10) %

- Output impedance: 1ΚΩ±3Ω

- Power consumption of the sensor: 4W

- Insulation resistance: >500MΩ

- Temperature while using: -20℃~+70℃

- Static overload: 150%

- Relative humidity: ≤ 90% RH

- Breaking load: 200%

- Signal output: 10±5KHz (Optional 4-20mA, 0-5V, 0-10V signal output / RS485)

- Measurement range: 5-1000N.m (customizable)

- Warranty: 12 months

Plug Connection and Lead Definition

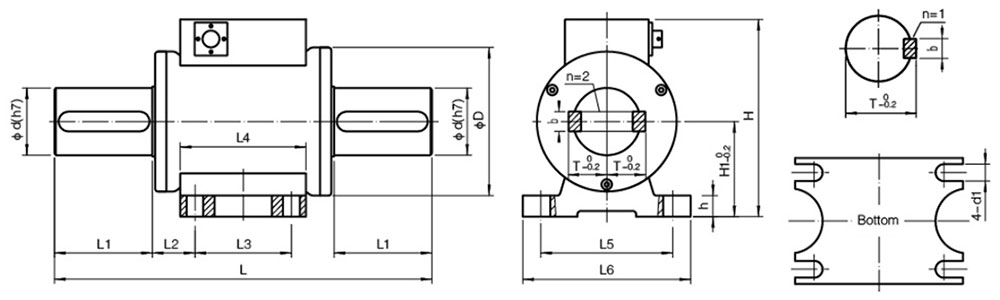

Torque Sensor Installation Dimension (unit: mm)

| Model | Capacity Range (N.m) |

MAx. Speed (r/min) | Dimension (mm) | Shaft Couping Size (mm) | Base Support Size (mm) | Weight (kg) | ||||||||||||

| H | L | D | d | b (p7)*n | T | L1 | L2 | L3 | L4 | L5 | L6 | H1 | d1 | h | ||||

| ZJ-5A | 5 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-10A | 10 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-20A | 20 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-30A | 30 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-50A | 50 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-100A | 100 | 6000 | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 35 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 3.8 |

| ZJ-200A | 200 | 5000 | 125 | 209 | 92 | 28 | 8*1 | 31 | 41 | 36.5 | 72 | 90 | 75 | 100 | 60 | 8 | 12 | 5.1 |

| ZJ-500A | 500 | 4000 | 135 | 238 | 96 | 38 | 10*2 | 22 | 55 | 37 | 72 | 90 | 75 | 100 | 65 | 8 | 12 | 6.5 |

| ZJ-1000A | 1000 | 3000 | 143 | 270 | 106 | 48 | 14*2 | 27.5 | 70 | 40.5 | 69 | 90 | 78 | 120 | 68 | 12 | 15 | 9 |

| ZJ-2000A | 2000 | 3000 | 143 | 270 | 106 | 48 | 14*2 | 27.5 | 70 | 40.5 | 69 | 90 | 78 | 120 | 68 | 12 | 15 | 9.5 |

| ZJ-5000A | 5000 | 2000 | 187 | 347 | 144 | 75 | 20*2 | 42 | 105 | 34 | 69 | 100 | 156 | 180 | 90 | 12 | 15 | 23 |

| ZJ-10000A | 10000 | 2000 | 214 | 389 | 158 | 98 | 20*2 | 55 | 118 | 36.5 | 80 | 110 | 170 | 200 | 110 | 14 | 15 | 35 |