- Stock: In Stock

- Model: PEACO-ADC200-I

- SKU: PEACO-ADC200-I

Available Options

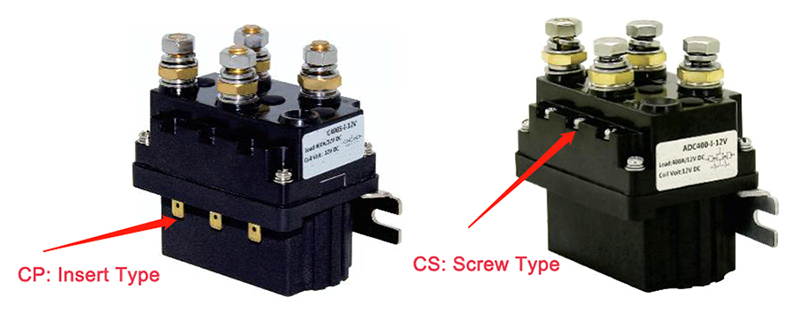

200A DC reversing contactor is equipped for intermittent working duty, Peaco Support has 12V dc reversing contactor, 24V dc reversing contactor, 48V dc reversing contactor, and other coil voltages that can be customized. The DC reversing contactor has two sets of switching contacts (2 NO and 2 NC contact forms) which can be used in auto electric winch and other various electric vehicles.

For a DC reversing contactor datasheet, please visit here Peaco Support DC contactor catalogue.pdf.

Bill of Materials (BOM)

- The upper cover of the DC reversing contactor is made of BMC material, which features high mechanical strength, good heat resistance (it can be used under 200℃ for a long time), and good aging resistance.

- DC motor reversing contactor adopts high-quality stainless steel material.

- The contact assembly uses high-quality and high-conductivity copper and silver contacts, which are reliable in contact, more durable and safer, and have an electrical life of over 30,000 times.

- The DC contactor comes with Teflon magnetic material, 500,000 movements without abrasion, temperature resistance of 155℃, and enameled wire.

- The base and coil frame are made of reinforced nylon PA66, which has high strength, high-temperature resistance, better flame retardancy, and electrical properties.

Applications

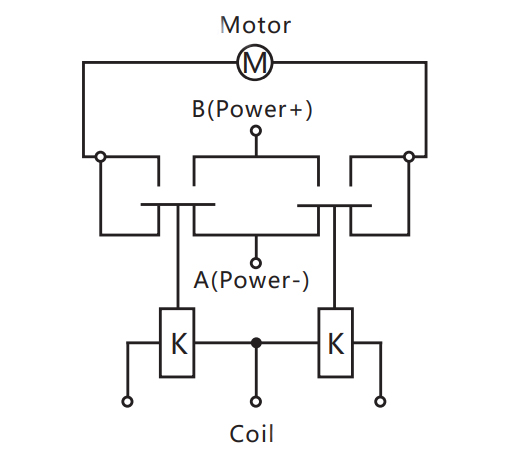

The 200A DC reversing contactor has two sets of switching contacts (2NO and 2NC DPDT Contacto Forms) which are used in electric control systems, such as automotive electric winches, telecommunications equipment, construction machinery, battery cars, electric forklifts, trains, ships, uninterrupted power supplies (UPS) and other electronic control systems.

Specification

| Physical Performance | Model | PEACO-ADC200-I | |

| Weight | 410g | ||

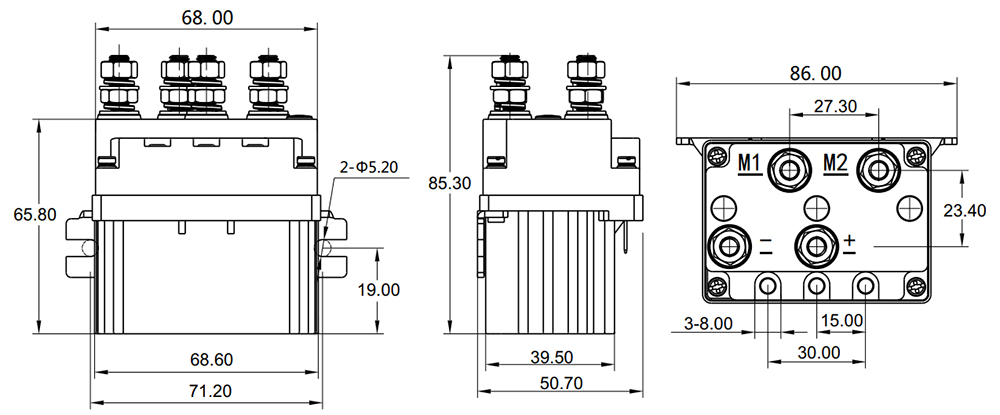

| Dimension | 81*52*76mm | ||

| Certification | CE, RoHS, ISO9001 | ||

| Warranty | 1 year | ||

| Contact Specification | Application | Intermittent 200A | |

| Operation Duty | Intermittent working duty | ||

| Contact Form | 2 NO and 2 NC | ||

| Electrical Life | 30,000 times, 200A and 24V DC | ||

| Max. Switching Current | ≤ 8Ie, ≤ 1s | ||

| Contact Voltage Drop | ≤ 80mV | ||

| Dielectric Withstanding Voltage | 50Hz/60Hz 1500VAC, ≤ 1min | ||

| Pull-In Time | ≤ 20ms | ||

| Drop-Out Time | ≤ 10ms | ||

| Max. Contact Bounce Period | ≤ 5ms | ||

| Load Terminal Size | M6 External | ||

| Insulation Resistance |

≥ 50MΩ |

||

| Coil Specification | Rated Voltage* | 12V/ 24V/ 36V/ 48/ 60V DC | |

| The Allowed Range of Coil Voltage | ±20% | ||

| Pull-In Voltage | ≤ 70% Us | ||

| Drop-Out Voltage | ≥ 5% Us, ≤ 40% Us | ||

| Coil Power | ≤ 25W | ||

| Starting Current | ≤ 4A | ||

| Contact Material | AgSnO/Cu or AgCuO/Cu | ||

| Mechanical Life | 300 thousand times | ||

| Use of Environment | Altitude | <2 km | |

| Humidity | 5%-85%RH | ||

| Temperature Range | -40℃~85℃ | ||

| Protection Grade | IP67 | ||

| Vibration | 20G Max. 80Hz-2000Hz | ||

| Impact | 50g, 11ms (Half-sine wave) | ||

200A DC Reversing Contactor Dimension (Unit: mm)

200A DC Reversing Contactor Wiring Diagram