- Stock: In Stock

- Model: PEACO-CJX2-18

- SKU: PEACO-ACC-3

Available Options

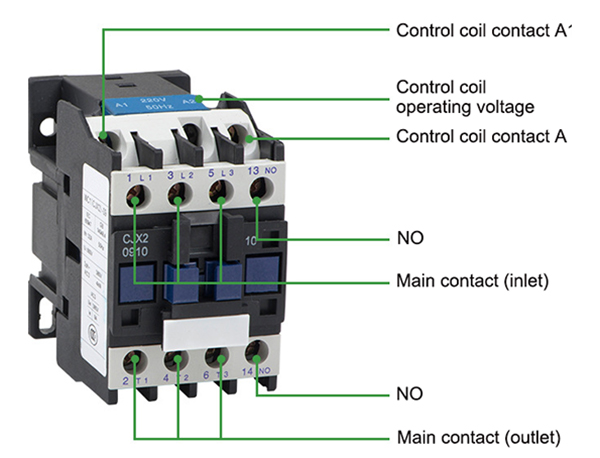

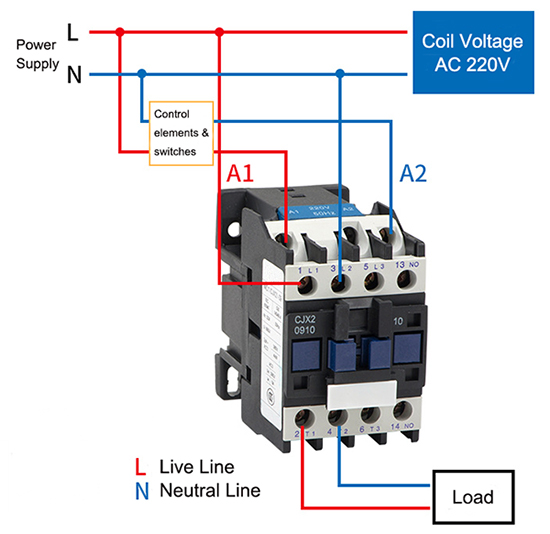

Peaco support provides a wide selection of CJX2 AC contactors. Contactor CJX2-1810 is such an AC contactor with 18A rated current and 3NO main contact and 1NO auxiliary contact, coil voltages are optional, including 24V, 48V, 110V, 220V AC, etc. Reliable 3 pole/ 4 pole AC contactors are suitable for long distance breaking circuit and frequently starting or control the motor.

AC Contactor Specifications

| Model | PEACO-CJX2-18 | ||

| Rated current* (optional) |

380V | AC-3 | 18A |

| AC-4 | 7.7A | ||

| 660V | AC-3 | 12A | |

| AC-4 | 3.8A | ||

| Conventional heating current | 32A | ||

| Rated insulation voltage | 690V | ||

| Power of controllable 3-phase squirrel cage motor (AC-3) | 220V | 4kW | |

| 380V | 7.5kW | ||

| 660V | 10kW | ||

| Operational frequency | Electric life | AC-3 | 1200 operations/h |

| AC-4 | 300 operations/h | ||

| Mechanical life | 3600 operations/h | ||

| Service life | Electric life | AC-3 | 1,000,000 operations |

| AC-4 | 200,000 operations | ||

| Mechanical life | 10,000,000 operations | ||

| Matching fusing model | RT16-25 | ||

| Average power consumption at 50Hz, 20℃ | Pick-up | 76VA | |

| Holding | 9.4VA | ||

| Pole* (Optional) | 3P+NO, 3P+NC | ||

| Weight | 0.35kg | ||

| Certification | CCC | ||

| Warranty | 2 years | ||

Note: For electricity-related maintenance and installation, make sure that the operator holds the qualification for electrical work and takes necessary power-off and insulation protection measures.

Features

- 32 pieces of iron core with solid materials, the suction is more smooth and tight.

- Provides silver alloy contacts with strong conductivity and flame retardant housing.

- With copper coils with strong electromagnetic suction when the coil is energized.

Normal Working and Installation Conditions

1. Ambient temperature: -5℃~+40℃, the average value should not exceed +35℃ within 24 hours.

2. Altitude: <2000m.

3. Atmospheric conditions: When the temperature reaches 40℃, the relative humidity of atmosphere should be <50%. When at relatively low temperatures, it could have higher relative humidity. Monthly maximum relative humidity could be not more than 90%. Special measures should be taken if there is occurrence of dews due to temperature changes.

4. Class of pollution: Class 3

5. Installation category. Ⅲ

6. Installation conditions: The inclination degree between the installation surface and the vertical surface does not exceed ±5°.

7. Impact shock: AC contactors should be installed and used in the place where there are no strong shakes and impacts.

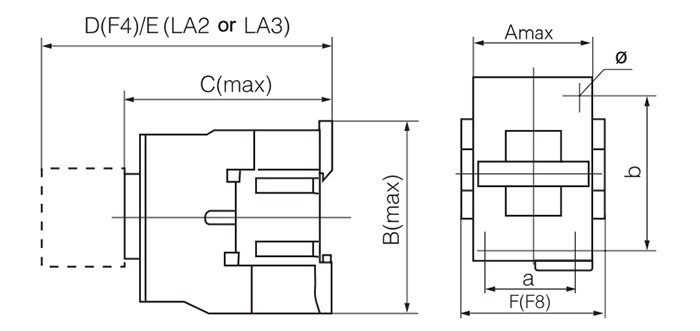

AC Contactor Dimension (Unit: mm)

Amax=47, Bmax=76, Cmax=82, Dmax=115, Emax=135, Fmax=73, a=35, b=50/60, Φ=4.5

- After the AC contactor coil is energized, the contactor does not move or acts abnormally.

- After the coil is powered off, the contactor does not release or delay release.

- The coil is damaged due to overheating.

- The electromagnet is too noisy.