- Stock: In Stock

- Model: GDK125-18-24Z/5.5

- SKU: PEACO-SPINDLE-15

Available Options

High power 5.5 kW Water cooled spindle motor provides high speed 18,000 - 24,000 rpm, working at three phase 220V/380V. High performance CNC spindle motor comes with ER25 nut and collet, grease bearing lubrication, low running noise and the constant torque spindle is well suitable for carving / engraving and milling.

Specifications

- Model: PEACO-GDK125-18-24Z/5.5

- Material: Stainless steel, copper, aluminum

- Power: 5.5 kW

- Torque: 2.92Nm-2.19Nm

- Voltage: 220V/380V

- Current: 19.0A/11.0 A

- Frequency: 300Hz-400Hz

- Speed: 18,000-24,000 RPM

- Cooling: Water-cooled

- Bearing Lubrication: Grease

- Number of Pole: 2 poles

- Joint of Nose: ER25 collet (Φ3.175 mm-Φ16.0 mm)

- Bearings Type: 7007C (P4)*2, 7005C (P4)*2

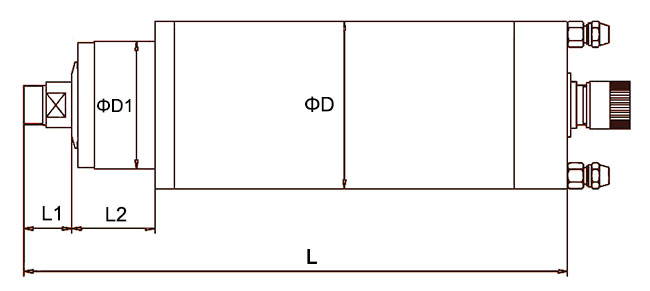

- Dimension: ØD=125mm, ØD1=100mm, L=365mm, L1=32.5mm, L2=56mm

- Rotating Mode: anticlockwise from the shaft extension end.

- Net Weight: 23kg

- Gross Weight: 32kg (packed with wooden box)

- Certification: CE

- Warranty: 1 year

Spindle Motor Dimension (Unit: mm)

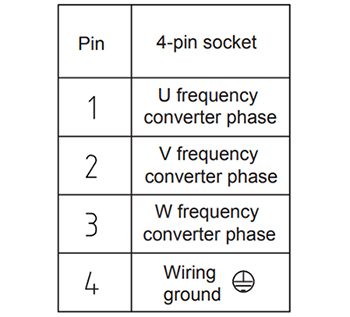

Spindle Motor Wiring

Warning:

1. The electric main shaft shall be installed at the clamped position, otherwise the bearing will be easily damaged.

2. The compressed air shall be dry and clean and the filtering accuracy shall be 0.1 micron. Atmospheric pressure is 0.1- 0.2 MPa and the air seal shall be normally open. It is recommended to use the two-level filtration with the filtration accuracy of 0.5 micron / 0.1 micron respectively and the air filter shall have automatic discharge device.

How to solve the heat dissipation problem of water-cooled spindle motor?

The water-cooled spindle bearing will generate a lot of heat when it rotates at high speed, causing the spindle to heat up. Additionally, the tool installed on the end face of the CNC spindle motor will also generate a lot of heat during high-speed cutting. Therefore, the spindle motor cooling during operation needs to be paid attention to. What's more, spindle cooling must be considered when designing the spindle motor structure.

During the high-speed operation of the water-cooled spindle motor, the internal power loss (including mechanical loss, electrical loss, etc.) causes the motor to heat up. Since the electric spindle motor is installed in the casing of the spindle unit, the spindle motor cannot be directly used for heat dissipation and the natural heat dissipation conditions are also poor. The experimental results show that when the spindle motor rotates at high speed, the working rotor temperature is 140-160℃ and the stator temperature is 45-85℃. The heat generated by the motor is directly transferred to the spindle, resulting in thermal deformation of the spindle and machining errors.

The purpose of the water-cooled spindle cooling circuit is to keep the spindle temperature stable, and its temperature has nothing to do with the spindle speed. Therefore, it can prevent the front end of the spindle from stretching and maintain the spindle bearing and then ensure that the accuracy of the spindle is not affected by the motor heat. The motor cooling circuit mainly lies in the cooling of the motor stator. As long as the stator temperature is controlled within a lower range, its temperature can be controlled. The cooling method is to use external circulating water coolant for forced cooling of the stator of the motor to strengthen the heat dissipation function of the motor to the outside, so that the shell of the main shaft part maintains the indoor temperature.

It is very necessary to use cooling method, because the temperature is too high, it will directly affect the normal operation of the spindle motor, so we must pay attention to the spindle temperature and cool it in time when using it.