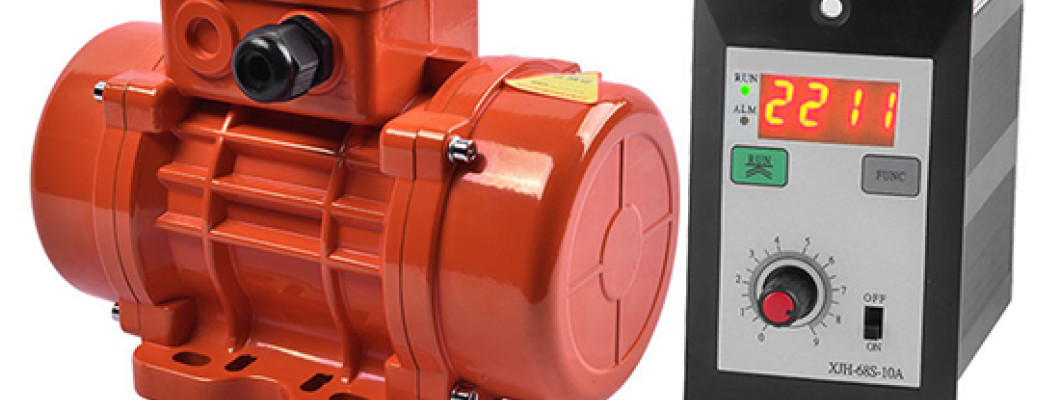

The vibration motor is equipped with a set of adjustable eccentric blocks at each end of the rotor shaft and the excitation force is obtained by the centrifugal force generated by the high-speed rotation of both the shaft and the eccentric block. The vibrating motor has large vibration frequency and the mechanical noise can be reduced only when the excitation force and power are properly matched.

Features of Vibration Motor

Vibration motor works well in the industrial field, which benefits from its features. Firstly, the excitation vibration force of the motor is matched with the power properly, the large vibration force is achieved, light motor weight, small size and low mechanical noise. What's more, the vibration motor provides a stable amplitude since the vibrating motor has vibration with a strong resistance instead of resonance. Addtionally, such an electric motor has large vibration frequency range. The vibration frequency of the electromagnetic exciter is fixed, which is generally equal to the power step rate and the vibration frequency of the vibration motor can be adjusted in a wide range by adjusting the speed and both the vibration frequency and amplitude can be selected at random according to different paths. The forth feature is that the vibrating motor has less fluctuations affected by power. Electromagnetic vibration exciters will cause large changes in the excitation force due to voltage changes. However, such changes are very less in vibrating motors. At last, vibrating motor is multi-machine combination and can realize self-synchronization and complete different process requirements.

Vibration Motor Application

The industrial vibration motor has high utilization rate of excitation force, low energy consumption, low noise and long working life. The excitation force of the electric vibrating motor can be steplessly adjusted for convenient use. P-MVE, P-YZS and P-VBE series of vibration motors from Peaco Support are universal vibrating motors, can be applied to general vibration machinery, such as vibration molding machine, vibration pile driver, vibration elevator, vibration crusher, vibration screening machine, vibration baler, vibration shakeout machine, vibration filling machine, etc. It is worth mentioning that there are a wide selection of vibrating motors for vibrating table on peacosupport.com. Vibration motors can be classified into AC vibration motors and DC vibration motors, which are widely used in hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, light industry and other industrial fields.

Types of Vibration Motor

According to the use occasion, vibration motors can be classified into ordinary vibration motors and explosion-proof vibration motors. According to the installation structure, there are two classifications of horizontal vibration motors and vertical vibration motors.

Horizontal vibration motor is different from other motors, which is a kind of excitation source that combines a power source and a vibration source. What is the structure of horizontal vibration motor? The horizontal vibration motor is mainly composed of two parts, one is a specially designed part to drive a three-phase asynchronous motor or a single-phase motor and the other is an exciting mechanical part with adjustable eccentricity and eccentric quality. Generally speaking, the horizontal vibration motor has a double-bearing structure, its casing is fully enclosed with a good heat dissipation function and a good mechanical strength so that it can be used in a variety of harsh environments. The motor's main shaft is designed reasonably, which can meet the needs of strong centrifugal force at both ends of the main shaft. Additionally, the structure of the motor coil, lead-out cable and junction box have the ability to withstand vibration.

Features of Horizontal Vibration Motor

- Fully enclosed. Usually, horizontal vibration motors are mainly used in places where there are a lot of dust. If they are not enclosed, it is easy to cause damage to various parts. Although it is closed, there are annular radiating ribs on the casing, which not only increases the heat dissipation rate and also increases the strength of the casing.

- Fixed feet. The horizontal vibration motor has fixed feet to ensure the structure stable when the excitation force is output.

- The spindle is short and thick. Such vibration motor has short and thick spindle to increase the spindle rigidity.

- Heavy-duty anti-vibration bearings. The powerful vibration motor is equipped with the heavy-duty anti-vibration bearings, which makes it convenient to transmit the exciting vibration force and also guarantees the working machine more stable and reliable.

- The junction box has the ability to withstand vibration. The motor coil, lead-out cable and junction box have special design and can withstand vibration.

Horizontal Vibration Motor Application

The horizontal vibration motor is a specially designed to drive a three-phase asynchronous motor, or in other words, it is actually a part of a single-phase motor, which is widely used in many occasions recently. The industrial vibration motors are mainly used in general vibration machinery, such as vibration crushers, vibration screening machines, vibration packers, vibration shakeout machines, vibration molding machines, vibration pile drivers, vibration elevators, vibration filling machines, etc. What's more important is that the horizontal vibration motor can also be combined with multiple vibration forms, such as flat rotation type, scroll type, shaking vibration type, combined linear type, combined oblong type, composite dual frequency type, composite double amplitude type, etc. These vibration forms can produce some new types of vibration machinery that were not available in the past.

Installation of Horizontal Vibration Motor

Horizontal vibration motors are mainly used in production to transfer granular or powdery substances to the receiving equipment through hoppers and vibrating belts or to achieve the effect of screening. This powerful vibration motor is widely used in industry and smelting. The vibration motor consists of a vibration exciter, a carrier, a shock-absorbing support and other related components and has the advantages of continuous feeding, long working life, low wear and low noise. However, there are many details needed to pay attention during installation and use. Here are some details about its installation and use.

1. Installation method

It is very necessary for users to instal the horizontal vibration strictly in accordance with the requirements. Generally, it is installed horizontally. If it cannot be installed horizontally, you can feel free to contact Peaco Support to consult the angle range of the installation. Generally speaking, it cannot exceed 10 degrees.

2. Identify the connection

The brushless vibration motor should be fixed after installation. The method and position of the fixation are very important. The connection position must be determined to ensure its firmness. If the motor installation is not firm enough, the working effect will be decreased and it will cause greater damage to the motor. .

3. Check whether the eccentric angle of the motor is the same.

Generally speaking, multiple horizontal vibration motors of the same model are installed on the same vibrating screen. Therefore, it is important to check whether the angle between the eccentric block and the fixed eccentric block of each vibrator is the same before use. When their vibration amplitudes are consistent then the motors can work normally.

4. Observe motors before working. After turning on the horizontal vibration motor, users should observe whether its operation is stable, whether there is obvious lateral movement, etc. and there are abnormal noise or not.

Maintenance and Troubleshooting for Horizontal Vibration Motor

Horizontal vibration motor is a vibration source that is installed in many equipment. If a failure occurs during use, it will definitely affect the normal operation of vibration motor equipment. Thus, regular maintenance should be done. The following is the methods of daily maintenance and troubleshooting to make motors perform better.

- Cleaning and maintenance. Do daily cleaning and maintenance. If the horizontal vibration motor is not cleaned in time, it will be covered with dust, which will affect the heat dissipation over time. If the heat dissipation of the equipment is not good, the internal parts will be burnt and even cause a fire. Therefore, the horizontal vibration motor should be maintained regularly, including putting lubricating oil, removing dust, anti-rust treatment and so on.

- Check the power line. The horizontal vibration motor will have electric leakage. Sometimes the ground wire is not connected properly or it is caused by the aging of the power cord. Whatever the reason is, the power line must be checked regularly. It is necessary to solve the short-circuit problem and replace the power cord in time if the insulation coating is off.

- Annual inspection. It is also important to pay attention to the annual inspection of the horizontal vibration motor. During the annual inspection, users should disassemble the motor to see if the internal components are normal and then install it correctly.

Advantages of Vertical Vibration Motor

What are the advantages of vertical vibration motors? The first is its good appearance design, which greatly improves the insulation and protection performance and such a vertical vibration motor can be widely used in humid working environments. The second advantage is its good vibration resistance. The lighter weight and smaller volume have greatly improved its excitation force. At the same time, this lightweight feature makes maintenance and installation much easier, which improves the motor's processing speed for materials. The third one is that the performance is relatively stable. The parts and components used in it have a higher standard, the starting speed has been much faster and it can maintain effective control in high-speed operation.

Application of Vertical Vibration Motor

Such electric vibrating motors are mainly used as a supporting facility, mainly used in vibrating crushers, vibrating cleaning machines and vibrating dryers.

How to Replace Vibration Motor Bearings?

- a. Remove the protective cover at both ends of the vibration motor (vertical vibration motor has no protective cover) and record the percentage value of the excitation force when the eccentric block is working, so that the original working state will be restored during installation.

- b. Remove the shaft rings at the two shaft ends.

- c. Loosen the fastening bolts of the outer eccentric block, the outer eccentric block and the shaft key. Then loosen the fastening bolts of the inner eccentric block and remove the inner eccentric block.

- d. Remove the bearing seat and tighten the bolts. Screw the bearing seat into housing with appropriate bolts, remove the screw hole and push the bearing seat out of the housing.

- e. Remove the bearing cover from the bearing seat, press out the bearing from the bearing seat or push it out with a suitable bolt.

- f. If the bearing is a cylindrical roller bearing with a separable inner and outer sleeve, remove the inner sleeve of the bearing from the shaft and put it into the original bearing outer sleeve.

- g. Clean the oil stains of all parts thoroughly.

- a. Wash the bearing with kerosene, press it into the bearing seat, fill the rollers of the outer ring of the bearing with 3# lithium base grease to two-thirds full, apply it evenly with a clean hand, install the bearing gland and press it with tightening bolts that are coated with anti-loosening glue.

- b. The bearing is a cylindrical roller bearing with a separable inner and outer and inner sleeve of the bearing should be sleeved on the rotating shaft and in place.

- c. Install the bearing seat on the casing. If there is a grease injection hole, it must be aligned with the position. Tighten the bearing seat with fastening bolts.

- d. Install the inner and outer eccentric block on the rotating shaft and place it in place. If there is a shaft key, install the shaft key in the keyway and then install the outer eccentric block, and install the shaft retaining ring on the rotating shaft.

- e. Tighten the fastening bolts of the eccentric block, turn the adjustable eccentric block to the angular position before removal and tighten the fastening bolts. After the above assembly is completed, the shaft should have a certain axial movement.

- f. Install and fasten the protective cover at both ends of the vibration motor with screws.

Leave a Comment