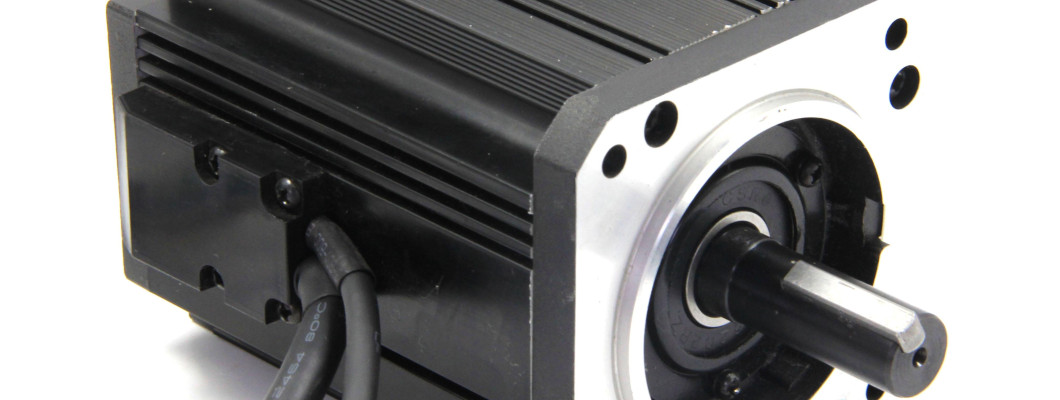

BLDC (also known as a BLDC motor or BL motor) is short for brushless direct current motor. It has major components as permanent magnet rotor, poly-phase armature winding on stator and hall sensor. The operation of BLDC is based on simple force of interaction between permanent magnet and electromagnet which can also be explained from Lorentz Law.

- Accurate torque and speed control provide higher efficiency and low power consumption.

- High torque and weight ratio make it suitable for robotics, space, medicine application where size is constrained.

- Number of electromagnet coils can be used on the stator for more precise and control on the operation.

- Better performance and efficiency as compared to brushed DC motors due to involvement of electronic control over the speed and position of the motor. BLDC motor life span is approximately 6 times higher than brushed DC motor.

- Easy to maintenance, MTBF of the motor is higher compared to general DC motor, which makes BLDC motor more efficient and reliable.

- Mechanical energy loss due to friction can be eliminated in BLDC motor due to absence of carbon brushes.

- Low operating noise as compared to other motor of same ratings and avoiding the use of brush contact in BLDC.

- No spark due to commutator in BLDC motor leads to minimize the burnout issue and it is more eco-friendly and safe to use.

- Low no-load current makes it suitable to operate at low or no load current.

- No heating issue resulting from absence of electromagnet in center of the BLDC motor.

Peaco Support offers a wide range of brushless motors to choose for your application including square & round inner rotor BLDC motors, flat outer rotor BLDC motors and high torque brushless DC motors. Square size frame ranges from 42*42mm , 60*60mm to 110*110mm, round inner rotor BLDC ranges from 22mm, 28mm to 57mm. What's more, the matching gearbox, encoders, brakes and connectors can be added for your complete application. For more details, you can visit brushless DC motors.

Leave a Comment