DC contactor is also called DC contactor relay, is such a contactor used in the DC circuit, mainly used to control the DC circuit (main circuit, control circuit and excitation circuit, etc.). The iron core of the DC contactor is different from that of the AC contactor, which has no eddy current. Therefore, it is generally made of mild steel or industrial pure iron into a round shape.

How does DC contactor work?

When the DC contactor coil is energized, the coil current generates a magnetic field, which makes the static iron core generate electromagnetic attraction to attract the moving iron core and drives the contact action - the normally closed contact is disconnected, the normally open contact is closed and both are linked. When the coil is powered off, the electromagnetic attraction disappears and the armature is released under the action of the release spring, so that the contacts are restored - the normally open contact is disconnected and the normally closed contact is closed.

DC contactors are widely used in DC motors that require long-distance connection or disconnection of DC circuits, as well as frequent start, stop, reverse and reverse braking, mainly play an important role in frequently connecting and disconnecting the electromagnetic coil of lifting electromagnet, solenoid valve, clutch.

DC contactors have two types of structures, namely, three-dimensional layout and plane layout and some products are derived on the basis of AC contactors. Therefore, the structure and working principle of the DC contactor are basically the same as that of the AC contactor, which is mainly composed of three parts: the electromagnetic mechanism, the contact system and the arc extinguishing device.

- Electromagnetic Mechanism

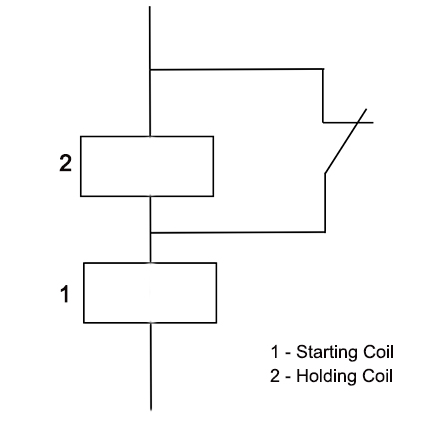

The electromagnetic mechanism is assembled by components such as iron core, coil and armature. Because there is DC current flowing in the coil, under normal working conditions, the eddy current phenomenon will not happen in the iron core. What's more, there will not exist heat and iron damage happening. There are more DC contactor coil turns, in order to make the coil dissipate well, the coil is usually wound into a long and thin cylindrical shape. Since the magnetic flux in the core is constant, shorting rings are also not required on the pole surface of the core. In order to ensure the reliable release of the armature, it is often necessary to place a non-magnetic gasket between the iron core and the armature to reduce the influence of residual magnetism. DC contactors above 250A often adopt double-winding coils as shown in the following figure (DC contactor wiring diagram).

Dual Coil DC Contactor Wiring Diagram

In the figure, the coil 1 is the starting coil, the coil 2 is the holding coil and a normally closed contact of the contactor is connected in parallel with the holding coil. At the moment when the circuit is just turned on, the coil 2 is short-circuited by the normally closed contact, so that the coil 1 can obtain a larger current and suction.

When the DC contactor operates, the normally closed contact is disconnected and both coil 1 and coil 2 are connected in series. Since the voltage remains constan, the current is small. However, the armature can still be pulled in, saving power and extending the service life of the electromagnetic coil.

- Contact System

DC contactors have main contacts and auxiliary contacts. The main contact is generally used as a single pole or a double pole. Since the current of the contact is relatively large, the finger contact for rolling contact is used. On the contrary, the current of the auxiliary contact is small, and the double-breakpoint bridge contact with point contact is often used.

- Arc Extinguishing Device

Since the DC arc does not have a natural zero-crossing point like the AC arc, when the main contact of the DC contactor breaks a large current, it is more difficult to extinguish the arc and a strong arc is often generated, which easily leads to burn the contacts and delay the power-off. In order to extinguish the arc quickly, the DC contactor generally adopts an arc extinguishing device with magnetic blowing and is equipped with a partition plate and a clay arc extinguishing cover, which DC contactors with small capacity also adopt.

Peaco Support, one DC contactor manufacturer and distributor, provides a wide selecion of DC contactors, whose coil rated voltage can be customized according to customer's needs, including 12V contactor relay, 24 volt DC contactor, 48V DC contactor, 110V DC contactor, 220V DC contactor. Its current ranges from 50A to 800A, such as 50A DC contactor, 100A DC contactor, 200 amp DC contactor, 300 amp DC contactor, 400A DC contactor, etc.

Leave a Comment